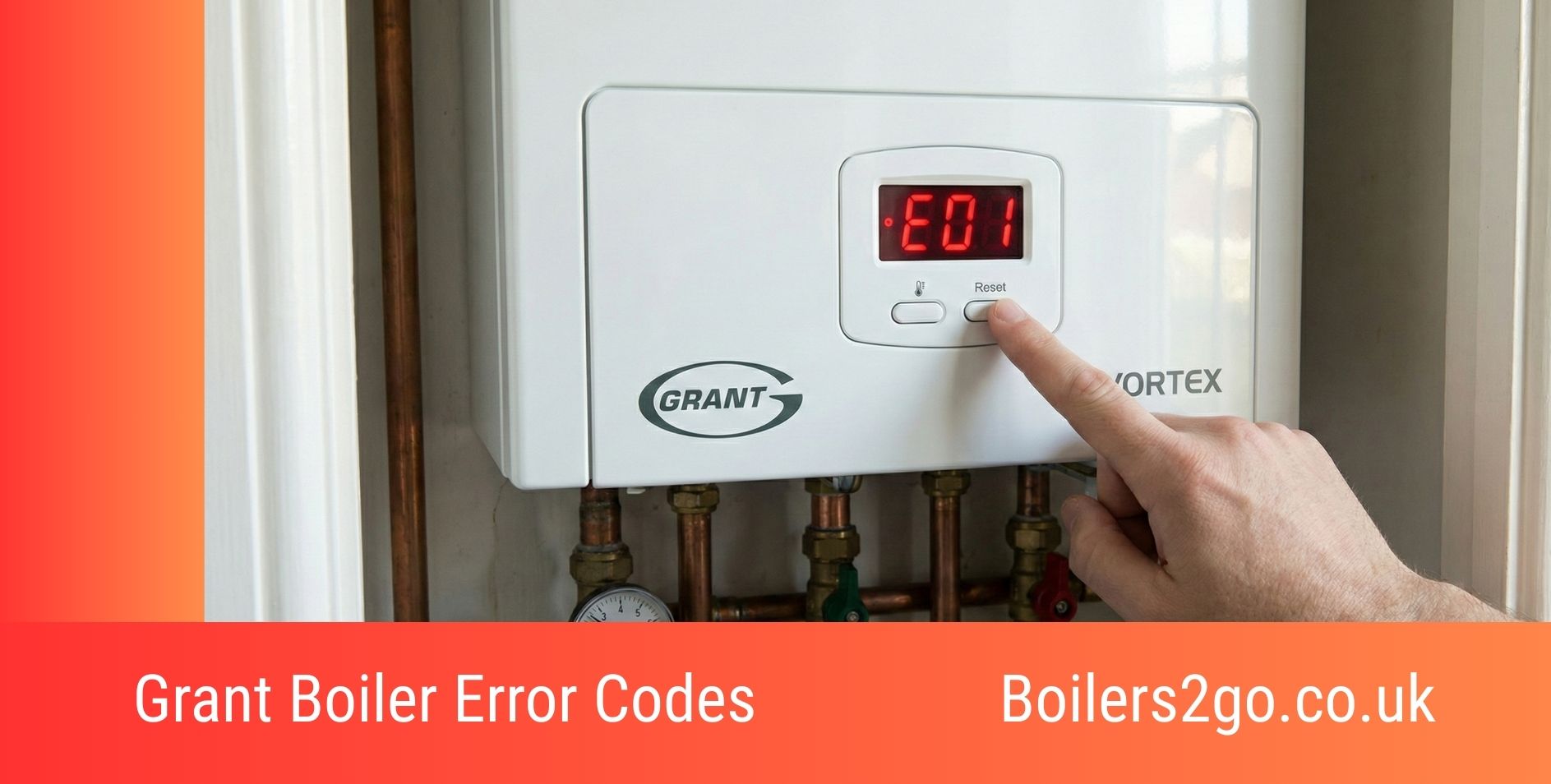

Grant boiler error codes are alphanumeric indicators displayed on the control panel of your Grant Vortex, Eco, or Pro series boiler, serving as a diagnostic tool for central heating faults.

These codes, often prefixed with ‘EE’ for electrical errors or ‘PP’ for protective functions, pinpoint irregularities in components like pressure sensors, thermostats, or ignition systems, allowing for swift intervention in oil boiler troubleshooting.

By interpreting these signals, homeowners can differentiate between simple resets and more complex issues requiring professional oil boiler servicing.

In this guide, I’ll explain the most common Grant boiler fault codes, discuss their meanings, root causes, and step-by-step fixes tailored for everyday users.

Most Common Grant Boiler Error Codes

Below, we’ve detailed the most frequent Grant boiler fault codes encountered by UK households. Each section breaks down the code’s meaning, potential causes with context, and targeted fixes. Remember, while some remedies are DIY-friendly, others demand an OFTEC engineer to ensure safety and warranty validity.

EE1: Low Water Pressure Fault

The EE1 error code on a Grant boiler indicates insufficient water pressure in the heating circuit, a common issue in sealed central heating systems where the gauge drops below 1 bar, preventing proper circulation and risking air locks or component strain.

What Causes the EE1 Error Code?

Low boiler pressure, as signalled by EE1, often stems from gradual water loss in the system, which is vital for distributing heat evenly through radiators and underfloor heating in UK homes.

Cause 1: Minor Leaks in Pipes or Radiators

Over time, small leaks develop at joints, valves, or radiator pinholes due to corrosion or thermal expansion, slowly depleting system water and triggering the pressure sensor in your Grant condensing boiler.

How to Fix Minor Leaks

- Inspect visible pipes and radiators for damp spots or drips; wipe dry and monitor for 24 hours.

- If confirmed, use a radiator key to bleed air from high points, then repressurise via the filling loop (a flexible hose connecting cold mains to the boiler).

- Turn the valves slowly until the gauge reads 1-1.5 bar, then close and test. For persistent leaks, seal with PTFE tape on threaded joints, but call an engineer if internal.

Cause 2: Faulty Pressure Relief Valve

The pressure relief valve, designed to vent excess water safely, can stick open from limescale buildup in hard water areas, causing continuous drainage and low pressure alerts on your oil-fired boiler.

How to Fix a Faulty Pressure Relief Valve

- Isolate the boiler by switching off power and fuel supply.

- Locate the valve on the boiler’s outlet pipe and gently lift the lever to flush debris; listen for water flow into the drain. If it doesn’t reseat, replace the valve—a straightforward swap using basic spanners—but only if you’re comfortable; otherwise, schedule an OFTEC service to avoid voiding your Grant warranty.

Additional Notes on EE1

If pressure stabilises post-fix but recurs, underlying sludge in the system may be the culprit; a power flush by a professional restores flow in older installations.

EE2: High Water Pressure Fault

EE2 signifies excessive water pressure above 2.5 bar in your Grant boiler’s hydraulic circuit, which can stress seals and gaskets, leading to leaks or boiler lockout in over-pressurised domestic hot water systems.

What Causes the EE2 Error Code?

Elevated boiler system pressure disrupts the equilibrium needed for efficient heat transfer, often arising from expansion issues in confined heating networks common in UK terraced homes or flats.

Cause 1: Air Trapped in the System

Air ingress during bleeding or from a recent refill creates compressible pockets that mimic high pressure when the boiler heats up, fooling the sensor in your Vortex model.

How to Fix Trapped Air

- Switch off the boiler and let it cool.

- Start at the lowest radiator, fitting a bleed key to the valve and turning anti-clockwise until a hiss indicates air escape; catch drips with a cloth.

- Repeat upstairs, working downwards, then check the boiler gauge.

- Top up if needed via the filling loop to 1 bar cold. Run the system for 15 minutes to purge remaining air.

Cause 2: Expansion Vessel Failure

The expansion vessel absorbs water volume increase during heating; if its diaphragm ruptures or air charge depletes, unchecked expansion spikes pressure, a frequent fault in unserviced Grant Eco boilers after 5-7 years.

How to Fix Expansion Vessel Failure

- Press the vessel’s Schrader valve (like a bike tyre) with a finger; if water sprays, it’s waterlogged.

- Use a pump to drain the system partially, then reinflate to 0.75 bar with a car compressor.

- Tap the vessel to check for a hollow ring—if muffled, replace the unit, ensuring compatibility with your boiler’s capacity (typically 8-12 litres for standard homes).

Additional Notes on EE2

Monitor with a pressure gauge kit; consistent highs may indicate a blocked vent, warranting a full system diagnostic.

PP7: Frost Protection Activated

The PP7 code activates Grant’s built-in frost protection, shutting down the boiler when temperatures plummet below 5°C to prevent freezing in external pipes or the unit itself, a vital safeguard for outdoor-installed oil boilers in rural UK properties.

What Causes the PP7 Error Code?

This protective lockout engages automatically in response to low ambient conditions, but persistent triggers point to sensor or circulation shortcomings in your home heating infrastructure.

Cause 1: External Temperature Drop Without Power

In unpowered states, like during outages, the frost stat detects sub-zero risks but can’t initiate a brief heat cycle, halting operations to avoid ice damage in vulnerable pipework.

How to Fix External Temperature Drop

- Restore electricity first, then reset by pressing the boiler’s frost override button (often integrated with the main switch).

- If outdoors, insulate exposed pipes with foam lagging and heat tape plugged into a thermostat-controlled socket.

- For landlords, install a remote frost stat linked to your smart heating controls for proactive warming.

Cause 2: Circulating Pump Seizure

The pump, responsible for minimal flow during frost mode, seizes from inactivity or limescale, preventing the protective warm-up and locking out with PP7 on your Grant Pro model.

How to Fix Circulating Pump Seizure

- Isolate power and fuel. Access the pump head via the boiler panel, removing the four screws.

- Gently rotate the shaft with a flathead screwdriver; if stuck, apply WD-40 sparingly and retry after 10 minutes.

- Reassemble, power on, and test circulation by feeling for vibrations. Lubricate annually during servicing to preempt recurrence.

Additional Notes on PP7

Common in exposed installations; pair with glycol antifreeze in vulnerable sections for extra defence against British winters.

Burner Lockout: Ignition Failure

A flashing lockout light (no specific code but often accompanied by a red neon) on Grant boilers denotes burner ignition failure, where the oil burner fails to light, starving your central heating of fuel and halting hot water production.

What Causes the Burner Lockout?

Ignition faults interrupt the combustion process essential for oil boiler efficiency, typically from supply or electrode disruptions in the firing sequence.

Cause 1: No Fuel Supply or Blockage

Depleted oil tank or clogged filter deprives the burner of kerosene, causing immediate shutdown to prevent dry firing and damage to the nozzle in your condensing heat exchanger.

How to Fix No Fuel Supply

- Check the tank gauge; if low, arrange a top-up from your oil supplier, ensuring clean delivery.

- Inspect the filter bowl under the boiler for sludge—drain via the plug into a bucket, rinse with kerosene, and refit.

- Prime the pump by bleeding air from the line until fuel flows steadily, then reset the burner button.

Cause 2: Faulty Electrodes or Photocell

Misaligned electrodes fail to spark, or a dirty photocell doesn’t detect flame, prompting lockout; dust from combustion residues accumulates over seasons in vented systems.

How to Fix Faulty Electrodes or Photocell

- Clean electrodes with fine emery paper, ensuring 3-5mm gaps per manual specs—adjust with tweezers if bent.

- Wipe the photocell lens with a lint-free cloth soaked in IPA.

- Realign using the boiler’s sighting glass, then test fire. For precision, an engineer uses a multimeter to verify resistance.

Additional Notes on Burner Lockout

Reset up to three times; repeated failures signal nozzle wear, fixable during annual OFTEC servicing.

Overheat Thermostat Trip: Red Neon Light

The overheat thermostat trip, indicated by a steady red neon light on the boiler panel, halts operations when internal temperatures exceed 90°C, protecting against scalding or component meltdown in your domestic heating appliance.

What Causes the Overheat Thermostat Trip?

Excessive heat buildup occurs when circulation falters, trapping warmth in the heat exchanger and bypassing safety limits in Grant’s multi-pass design.

Cause 1: Airlock in Heat Exchanger

Trapped air bubbles impede water flow, causing localised boiling and thermostat activation, exacerbated in sludgy systems common in older UK rentals.

How to Fix Airlock in Heat Exchanger

- Cool the boiler fully. Open all radiator bleed valves sequentially from lowest to highest, refilling via the loop to expel air.

- Tilt the boiler slightly if accessible to dislodge bubbles, then run on low heat for 30 minutes, bleeding as needed.

- Add a system cleanser like Fernox F3 for ongoing prevention.

Cause 2: Thermostat Sensor Malfunction

A faulty overheat stat probe misreads temperatures due to wiring corrosion or calibration drift, falsely tripping and disrupting reliable hot water supply.

How to Fix Thermostat Sensor Malfunction

- Disconnect power. Unclip the stat from its bracket, testing continuity with a multimeter (should read closed below 90°C).

- If open, replace with a compatible Grant part, soldering joints securely.

- Calibrate by immersing in hot water if adjustable, but defer to an engineer for electrical safety.

Additional Notes on Overheat Thermostat

Reset by pressing the red reset button post-cooling; integrate with a magnetic filter to catch debris early.

How to Prevent Grant Boiler Error Codes in the Future

Preventing Grant boiler faults starts with proactive maintenance, ensuring your oil-fired condensing system runs smoothly year-round. Schedule annual OFTEC servicing to clean the burner, check electrodes, and flush the heat exchanger, catching issues like sludge buildup before they trigger codes.

For homeowners, monitor pressure weekly via the gauge, topping up as needed, and insulate pipes to combat frost risks—essential for external Vortex models. Landlords should log services in tenant handbooks, promoting radiator bleeding quarterly to avoid airlocks.

Invest in a boiler filter to trap debris, and consider smart controls for remote monitoring, reducing energy waste by up to 10% in UK homes. Finally, use quality kerosene from trusted suppliers to minimise nozzle clogs, extending your boiler’s lifespan beyond the standard 10-15 years.

When You Absolutely MUST Call a Gas Safe Engineer

While minor tweaks like bleeding radiators are within reach, certain scenarios demand immediate intervention from a Gas Safe-registered engineer (or OFTEC for oil specifics) to avert hazards in your central heating setup.

Call without delay if error codes persist after resets, indicating deeper electrical or gas-related faults that could lead to carbon monoxide risks. Leaking fuel lines, unusual smells, or boiler noises like banging signal combustion issues requiring professional diagnostics.

For landlords, any warranty claim or post-service recurrence necessitates expert verification to comply with UK housing standards. If your Grant boiler is over 10 years old and faults multiply, a safety inspection prevents escalation—remember, unqualified tampering voids guarantees and endangers occupants.

FAQs

How Can You Read and Reset Grant Boiler Error Codes?

Reading Grant boiler error codes involves noting the flashing display on the boiler’s front panel, where symbols like a spanner icon or specific numbers appear during a fault.

To reset, locate the reset button, typically a red or black switch on the control box—and press it firmly after addressing any obvious issues, such as checking fuel levels.

Always consult your Grant boiler manual for model-specific instructions, as improper resets could exacerbate problems in your central heating setup.

How often should I service my Grant boiler to avoid error codes?

Annual servicing by an OFTEC engineer is recommended, focusing on combustion efficiency and component checks, which can prevent up to 80% of common faults like ignition lockouts in oil systems.

Can weather conditions trigger multiple Grant boiler faults at once?

Yes, extreme cold snaps often cascade issues like PP7 alongside EE1 from frozen pipes, so combining frost protection with insulated pipework is key for resilient home heating.

What’s the difference between Grant Vortex and Eco error code displays?

Vortex models use LED icons with numeric codes for broader diagnostics, while Eco series emphasise text messages on digital panels, aiding quicker identification in compact installations.

Do Grant boilers have self-diagnostic features beyond error codes?

Indeed, integrated sensors log historical faults via the control PCB, allowing engineers to retrieve data for predictive maintenance during routine oil boiler tune-ups.

How does water quality affect Grant boiler pressure-related errors?

Hard water accelerates limescale in valves and vessels, amplifying EE1/EE2 occurrences; installing a water softener extends component life in lime-prone UK regions.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.