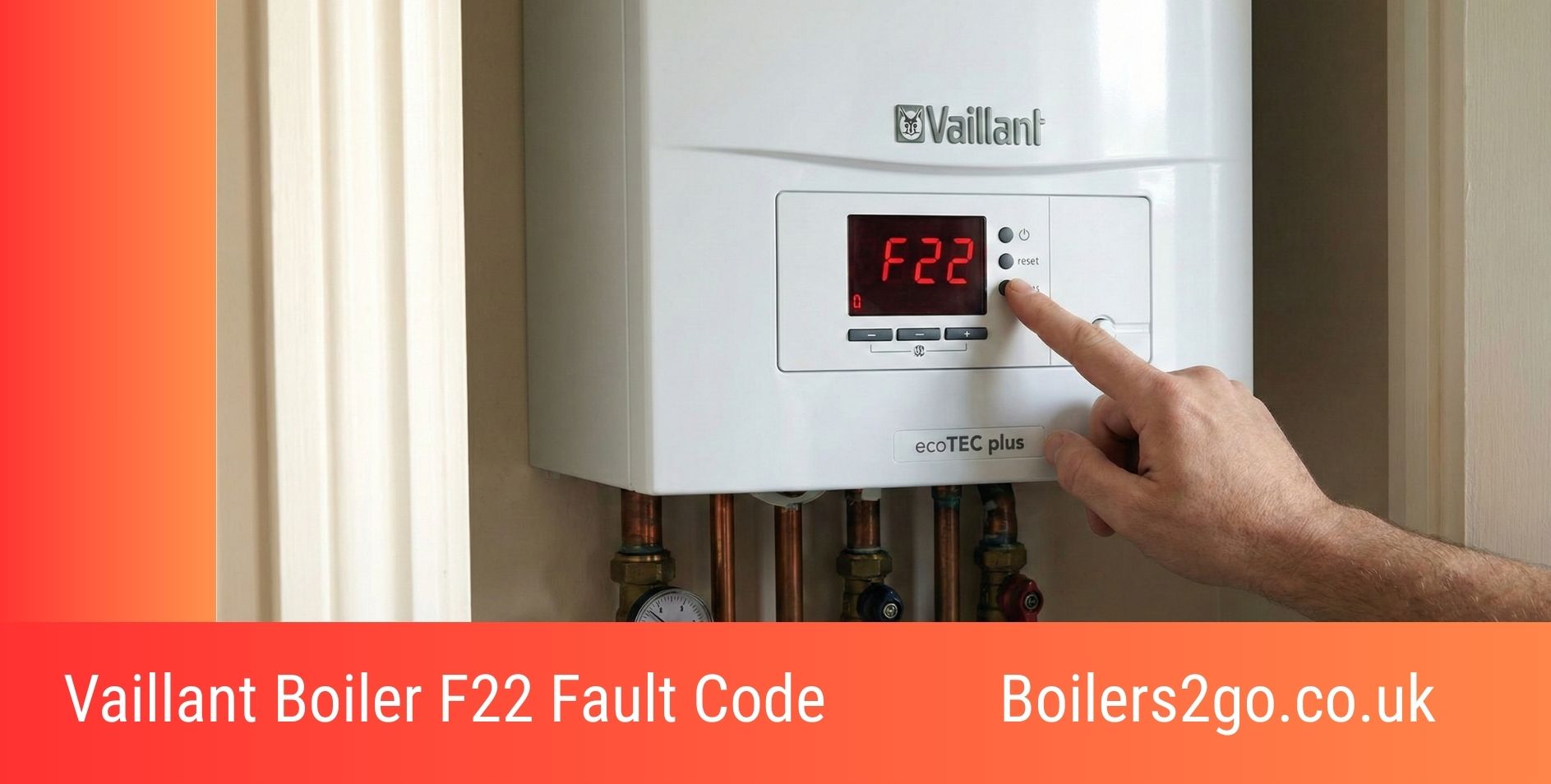

The Vaillant boiler F22 fault code is a diagnostic alert that appears on the control panel of your Vaillant boiler when the system detects insufficient water pressure in the central heating circuit.

Typically, this happens when the pressure drops below 0.5 bar, far from the ideal 1-1.5 bar range needed for safe and effective operation of models like the ecoTEC Pro or Plus series. As a safety measure, your boiler locks out, stopping both hot water supply and radiator heating to avoid overheating or component failure.

This error code is part of Vaillant’s user-friendly fault-finding system, where alphanumeric displays like F22 help pinpoint issues quickly. For context, in a typical UK home heating setup, water pressure maintains the flow through pipes, radiators, and the heat exchanger in your gas boiler.

When it’s too low, air pockets or dry-running risks emerge, potentially leading to bigger problems like scale buildup in hard water areas. Homeowners often notice the F22 code flashing alongside a red light or audible beep, especially during cold snaps when demand spikes.

In this guide, I’ll break down everything you need to know about the Vaillant boiler F22 fault code and provide step-by-step fixes—empowering you to restore warmth to your home efficiently and safely.

What Causes the Vaillant Boiler F22 Fault Code?

The Vaillant boiler F22 fault code arises primarily from low water pressure in the closed-loop central heating system, but several underlying factors can trigger this drop. These range from everyday wear in older installations to specific component failures in modern condensing boilers.

Recognising the root cause early prevents escalation, such as corrosion in the heat exchanger or inefficiency in your overall home heating performance. Below, we explore the most common culprits, tailored for UK households where seasonal demands and water quality play key roles.

System Leaks Leading to Pressure Loss

One of the top reasons for the Vaillant boiler F22 fault code is a leak somewhere in your central heating system, which gradually drains water and reduces pressure below the sensor’s threshold.

Leaks can be visible, like drips from radiator valves, or hidden, such as corrosion inside pipes or at joints in underfloor heating runs.

In UK homes, especially those with older pipework in Victorian-era properties, limescale from hard water exacerbates this by weakening seals. For landlords, unchecked leaks might breach gas safety regulations, leading to voided insurance or fines.

How to Fix System Leaks Causing the F22 Error

- To address leaks triggering the Vaillant boiler F22 fault code, start with a visual inspection: Check radiators, valves, and exposed pipes for damp spots, water stains, or hissing sounds.

- Wipe surfaces dry and monitor for re-wetting over 24 hours. If you spot a minor external leak, like a loose compression joint, turn off the boiler, isolate the water supply, and tighten fittings with a spanner—avoid over-tightening to prevent cracking.

- For radiator leaks, drain the system partially using the drain cock at the lowest point, then apply PTFE tape to threads before refitting.

- Once fixed, repressurise by locating your filling loop (a flexible hose connecting mains cold water to the boiler’s inlet).

- Open the valves slowly until the gauge hits 1.2 bar (cold system), then close and bleed radiators from top to bottom to release trapped air, which can mimic pressure drops.

- Reset the boiler by holding the button for three seconds. If the leak is internal—evidenced by sludge or discoloured water—flush the system with a chemical inhibitor like Fernox F3, added via a radiator or MagnaClean filter.

- Test pressure stability over a week; if it holds, you’ve resolved it. For persistent issues, note the location and severity for your Gas Safe engineer.

Faulty Pressure Relief Valve (PRV) Releasing Excess Water

A malfunctioning pressure relief valve (PRV) is another frequent cause of the Vaillant boiler F22 fault code, where this safety device—designed to vent excess pressure above 3 bar—sticks open or discharges prematurely, leading to unintended water loss and rapid pressure decline.

In high-pressure UK mains systems, especially in flats with shared risers, a worn PRV diaphragm can fail after 5-7 years, often due to debris or manufacturing defects in ecoTEC models.

How to Fix a Faulty PRV Triggering the F22 Fault

- Fixing a faulty PRV causing the Vaillant boiler F22 fault code begins with isolation:

- Switch off the boiler at the fused spur, turn off the gas supply, and drain the system via the lowest drain point to relieve tension. Inspect the PRV (usually on the boiler’s top or side outlet pipe) for corrosion, leaks, or unusual wetness around the discharge pipe, which should route to a drain. If it’s dripping steadily, this confirms the issue—do not attempt disassembly yourself, as it involves high-pressure components.

- Instead, cap the discharge temporarily with a compression fitting if safe, then repressurise to 1 bar and monitor.

- For a full repair, a Gas Safe engineer will replace the PRV cartridge (costing £50-£100 parts), using tools like a pipe cutter for seamless integration. Post-replacement, they’ll pressure-test to 1.5 bar and add inhibitor to prevent future blockages.

Homeowners can aid by ensuring the boiler’s annual service includes PRV checks; landlords should log this in property maintenance schedules to avoid tenant disputes during winter.

Malfunctioning Pressure Sensor Misreading Levels

The Vaillant boiler F22 fault code can also stem from a defective pressure sensor (or gauge), which inaccurately reports low levels even when the system is adequately filled—often due to electrical faults, sensor scaling from hard water, or wiring corrosion in damp airing cupboards.

This electronic component in Vaillant combi boilers sends data to the PCB (printed circuit board), and a glitch here fools the system into lockdown, common in models over three years old exposed to UK humidity fluctuations.

How to Fix a Malfunctioning Pressure Sensor for the F22 Error

- To remedy a malfunctioning pressure sensor behind the Vaillant boiler F22 fault code, first verify readings: Compare the boiler’s digital gauge to a manual test gauge attached at the PRV test point. If discrepancies exceed 0.2 bar, the sensor is likely faulty.

- Power down the boiler completely, then access the sensor (typically a small brass unit on the flow pipe, secured by two screws—consult your model manual for exact location).

- Clean visible scale with a vinegar-soaked cloth if accessible, but avoid solvents that could damage seals.

- Reconnect wiring firmly, checking for frayed leads with a multimeter set to continuity (beeps indicate good connection).

- Repressurise to 1.5 bar and reset; if the code clears temporarily but returns, replacement is needed—a £20-£40 part installed by an engineer to recalibrate the system.

For prevention, integrate this into your boiler service; in rental properties, document sensor health in EPC assessments to highlight efficiency.

Issues with the Expansion Vessel

An undercharged or failed expansion vessel causes the Vaillant boiler F22 fault code by failing to absorb water expansion during heating cycles, leading to pressure swings and drops as the diaphragm ruptures or air charge depletes.

In UK sealed systems, these vessels (pre-charged to 0.75 bar) are vital for stability, but bladder wear from thermal cycling affects 10-year-old installations, especially in unvented setups without regular checks.

How to Fix Expansion Vessel Problems Causing F22

- Resolving expansion vessel issues for the Vaillant boiler F22 fault code starts with diagnosis: With the system cold and drained, remove the vessel’s dust cap and press the Schrader valve—listen for a hiss indicating low air (should hold 0.75 bar via a bike pump with gauge). If water spurts out, the diaphragm is burst. Isolate the vessel by closing isolation valves, then depressurise fully.

- For recharging, pump air to 0.75 bar (matching static head), refit, and repressurise the system to 1 bar.

- If faulty, replace the vessel (£80-£150), involving pipe disconnection and bracket remounting—best left to pros to avoid air ingress.

- Bleed the entire system post-fix and monitor for 48 hours. Landlords benefit from annual vessel inspections in multi-tenant blocks to comply with HHSRS (Housing Health and Safety Rating System).

Bleeding Radiators or Trapped Air in the System

Recently bleeding radiators without repressurising can trigger the Vaillant boiler F22 fault code, as releasing air expels water, dropping pressure temporarily. Trapped air bubbles from poor circulation or post-installation settling exacerbate this in looped pipework, common in UK extensions where gradients aren’t optimised.

How to Fix Bleeding Radiators or Trapped Air for the F22 Fault

- To correct bleeding radiators or trapped air causing the Vaillant boiler F22 fault code, systematically bleed all upstairs radiators first (thermostatic valves open), using a radiator key to vent air until steady water flows—place a cloth underneath to catch drips. Work downstairs next, then repressurise via the filling loop to 1.2 bar.

- For deeper air locks, fit an automatic air vent on high points or use a spirovent separator.

- Run the pump on its own for 30 minutes to circulate, then reset the boiler. If gurgling persists, add a system cleanser to dislodge sludge. This DIY fix suits homeowners; for landlords, include in tenant handovers to encourage prompt bleeding during efficiency tweaks.

How to Prevent the Vaillant Boiler F22 Fault Code in the Future

Preventing the Vaillant boiler F22 fault code ensures reliable home heating and avoids disruptive winter breakdowns.

Schedule annual Gas Safe servicing to check pressure components, using Vaillant-approved inhibitors against corrosion in hard water regions like the South East.

Monitor the gauge monthly—aim for 1-1.5 bar cold—and repressurise proactively if below 1 bar. Install leak detectors near boilers and radiators, especially in basements, and flush systems every 3-5 years to clear debris.

For landlords, mandate quarterly checks in tenancy agreements and upgrade to smart Vaillant controls for remote pressure alerts. These steps boost efficiency, cut energy bills under EPC ratings, and extend your condensing boiler’s lifespan to 15+ years.

When You Absolutely MUST Call a Gas Safe Engineer

While many Vaillant boiler F22 fault code fixes are DIY-friendly, call a Gas Safe registered engineer immediately if pressure drops recur after repressurising, indicating hidden leaks or component failures that risk carbon monoxide exposure or explosions.

Also summon help for electrical faults (e.g., sensor wiring), if you’re uncomfortable with isolation procedures, or post any gas smell—never bypass lockdowns. In rentals, urgent calls prevent legal liabilities under the Gas Safety Regulations 2018. Expect £80-£150 for diagnostics; verify credentials via the Gas Safe Register app.

FAQs

How Does the Vaillant Boiler F22 Fault Code Differ from F75?

Unlike the F22, which flags general low water pressure, the F75 error specifically points to a pump overrun or airlock in the circulation pump, often after recent servicing. Both halt heating but require distinct checks—F75 might need pump impeller cleaning, while F22 focuses on system-wide pressure.

Can Hard Water in My Area Worsen the F22 Error on a Vaillant Boiler?

Yes, regions with hard water like London or the Midlands accelerate limescale on sensors and valves, mimicking or causing F22 triggers. Installing a water softener or magnetic descaler can mitigate this, preserving pressure stability without frequent interventions.

Is the F22 Fault Code Covered Under Vaillant Boiler Warranty?

Typically yes, if within the 2-10 year warranty period and serviced annually by an approved installer. Exclusions apply for misuse or neglected maintenance—always retain service logs to claim free repairs on pressure-related parts.

How Long Can I Safely Run My Vaillant Boiler with an F22 Error Before Damage?

No more than a few hours, as dry-running risks heat exchanger cracks costing £500+. Shut down promptly via the isolator switch and address to safeguard efficiency and comply with UK building regs on safe heating appliances.

Does Upgrading to a Vaillant Hydrogen-Ready Boiler Reduce F22 Occurrences?

Hydrogen-blend models like the ecoTEC Hydrogen incorporate advanced pressure monitoring and self-diagnosing sensors, potentially cutting F22 incidents by 20-30% through better resilience to fluctuations—ideal for forward-thinking homeowners eyeing net-zero transitions.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.