Boiler corrosion is one of the most common—and potentially most expensive—issues affecting UK boilers. Whether you’re a homeowner trying to keep repair bills down or a landlord wanting to prevent costly callouts, understanding why corrosion happens and how to stop it is essential.

In this guide, I’ll break down the causes of boiler corrosion, how each issue can be fixed, and how to prevent corrosion from developing in the first place. I’ll cover system water quality, leaks, limescale, oxygen ingress, rust development, and component failure in a clear, easy-to-understand way.

What is boiler corrosion?

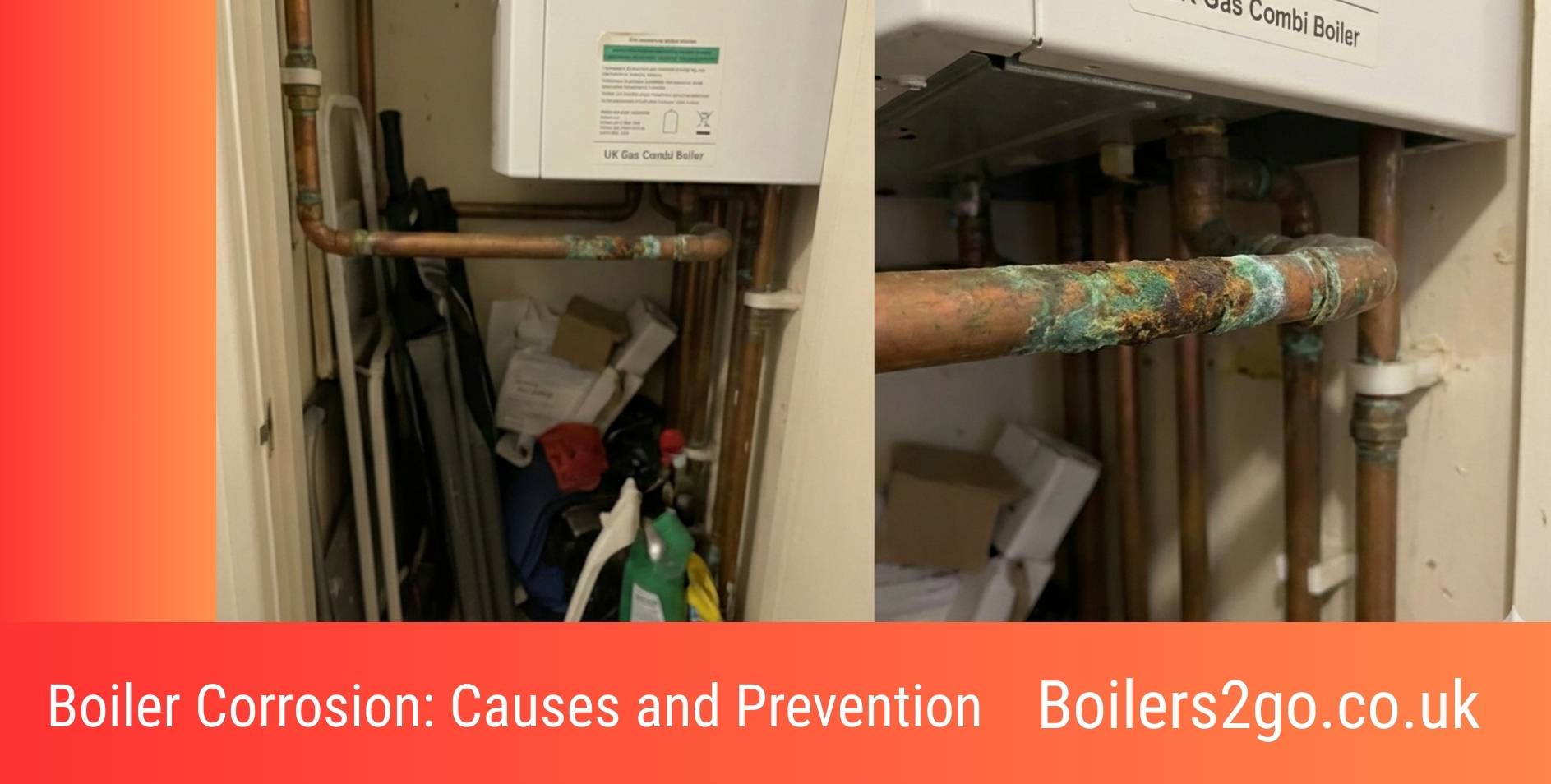

Boiler corrosion is the gradual breakdown of internal boiler components—usually metal parts—caused by chemical reactions such as oxidation, limescale buildup, acidic system water, or leaks. When corrosion starts, it weakens essential components like the heat exchanger, pipes, radiators, and internal seals.

Over time, this can lead to leaks, reduced efficiency, noisy operation, and complete boiler failure.

In the UK heating industry, corrosion is responsible for a large portion of boiler breakdowns, especially in areas with poor water quality or hard water. Left untreated, it can shorten the lifespan of your boiler by years.

Causes of Boiler Corrosion

Below are the main causes of corrosion inside modern boilers and heating systems, along with detailed explanations and fixes.

Why does oxygen ingress cause boiler corrosion?

Oxygen ingress causes boiler corrosion because oxygen encourages oxidation, which leads to rust, weakened metal surfaces, and sludge formation inside the system.

Oxygen enters sealed heating systems through several faults or defects:

1. Micro-leaks in pipework, joints, or radiators

Micro-leaks allow oxygen to continually seep into the heating system, creating a cycle of oxidation and rust.

How to fix micro-leaks in heating systems

To fix micro-leaks:

- A Gas Safe engineer must inspect the system for weeping joints, pinhole leaks, or failing radiator valves.

- Damaged joints are re-sealed, fittings tightened, or faulty valves replaced.

- After repair, the system water should be flushed and treated with corrosion inhibitor to remove oxygen-rich water.

2. Faulty automatic air vents

Automatic air vents are designed to release trapped air. When faulty, they may allow air into the system instead of releasing it.

How to fix faulty automatic air vents

Fixing this usually includes:

- Replacing the faulty air vent.

- Checking system pressure levels.

- Bleeding radiators and rebalancing the system.

- Adding corrosion inhibitor to protect internal components.

3. Low system pressure

Low pressure pulls air into the system through radiator valves and joints.

How to fix low system pressure

- Repressurise the system using the filling loop (if safe to do so).

- Inspect for leaks causing the pressure drop.

- If pressure continues falling, a Gas Safe engineer must assess the expansion vessel and PRV (pressure relief valve).

Why does acidic system water cause boiler corrosion?

Acidic system water causes boiler corrosion because low pH levels eat away at internal metals, damaging heat exchangers, radiators, and pipework.

What causes acidic system water?

Acidity is usually the result of:

- Lack of corrosion inhibitor

- Bacterial growth in stagnant water

- System sludge breaking down into acidic compounds

- Chemical imbalance due to contamination

1. Lack of corrosion inhibitor

Without inhibitor, system water becomes corrosive.

How to fix lack of inhibitor

- Drain and refill the system.

- Add a high-quality corrosion inhibitor (e.g., Fernox, Sentinel).

- Consider installing a Magnaclean filter for ongoing sludge protection.

- Check inhibitor levels annually during servicing.

2. Bacterial contamination

Bacteria thrive in dirty or stagnant heating systems, producing organic acids that attack metal components.

How to fix bacterial contamination

- A full powerflush or chemical flush is needed.

- After flushing, add inhibitor and possibly a biocide treatment.

- Ensure the system is correctly balanced and circulating properly.

Why does limescale cause boiler corrosion?

Limescale causes boiler corrosion because scale creates hotspots on metal surfaces, leading to overheating, cracks, and accelerated corrosion—especially in hard water areas.

What causes limescale build-up?

- Untreated hard water entering the boiler

- Lack of a limescale reducer

- Limescale deposits forming on heat exchangers

1. Hard water entering the boiler

The UK has widespread hard water, especially in the South and Midlands.

How to fix hard water issues

- Install a limescale reducer or water softener.

- Fit a scale inhibitor on the cold feed to the boiler.

- Descale the heat exchanger if limescale has already formed.

2. Limescale on the heat exchanger

A scaled heat exchanger can overheat and corrode rapidly.

How to fix a scaled heat exchanger

- A Gas Safe engineer must chemically descale or replace the heat exchanger.

- Install scale prevention devices to stop recurrence.

Why do leaks inside the boiler cause boiler corrosion?

Leaks inside the boiler cause boiler corrosion because water exposure damages components, and leaking joints introduce oxygen, accelerating rust formation.

What causes internal boiler leaks?

- Perished seals

- Faulty heat exchanger

- Loose fittings

- Corroded pipework

1. Perished internal seals

Seals wear down over time due to heat and pressure cycles.

How to fix perished seals

- A Gas Safe engineer replaces the faulty seals.

- The system is inspected for further signs of corrosion.

- Pressure and safety controls are tested.

2. Cracked or leaking heat exchanger

This is one of the most serious corrosion outcomes.

How to fix a cracked heat exchanger

- In most cases, the heat exchanger must be replaced.

- For older boilers, replacement is generally more cost-effective than repair.

3. Loose internal fittings

Loose joints inside the boiler can release small amounts of water.

How to fix loose fittings

- Tighten or replace the fittings.

- Inspect and dry the internal boiler casing.

- Test the boiler for pressure stability.

Why does sludge cause boiler corrosion?

Sludge causes boiler corrosion because it is made from rust, dirt, and metal debris, which accelerates further corrosion and blocks circulation.

What causes boiler sludge?

- Rusting radiators

- Untreated system water

- Lack of inhibitor

- Long periods without servicing

1. Rusting radiators

Internal radiator corrosion releases iron oxide sludge.

How to fix radiator rust

- Replace severely corroded radiators.

- Flush the system.

- Maintain inhibitor levels.

2. Untreated system water

Water with contaminants encourages chemical reactions.

How to fix untreated water issues

- Perform system flush.

- Add appropriate chemicals (inhibitor and cleaner).

- Fit a magnetic filter for ongoing sludge collection.

How to Prevent Boiler Corrosion in the Future

Preventing boiler corrosion involves ongoing maintenance rather than one-off fixes. Best practices include:

- Maintain inhibitor levels—check annually during servicing.

- Install a magnetic filter to capture iron oxide and sludge.

- Ensure all system leaks are repaired promptly.

- Consider limescale protection in hard water areas.

- Annual boiler servicing to detect corrosion early.

- Install a system filter and flush every 5–7 years.

Keeping your heating system clean and chemically balanced is the single most effective way to prevent corrosion long-term.

When You Absolutely MUST Call a Gas Safe Engineer

Call a Gas Safe engineer immediately if:

- Your boiler is leaking water internally or externally.

- You suspect the heat exchanger is cracked.

- You notice repeated pressure loss despite topping up the system.

- The boiler makes banging, kettling, or metallic grinding noises.

- There is visible rust inside the boiler casing.

- You smell gas or suspect carbon monoxide (turn off the boiler and call emergency services).

Corrosion-related failures can escalate quickly, so never ignore signs of internal damage.

FAQs

Does boiler corrosion mean I need a new boiler?

Not always. Minor corrosion on external fittings or early-stage internal corrosion can often be repaired. However, advanced corrosion—especially on the heat exchanger—usually means replacement is more economical.

How long should a boiler last before corrosion becomes a problem?

Most modern boilers last 10–15 years, but corrosion can start much earlier in systems with poor water quality or no inhibitor protection.

Can corrosion cause high energy bills?

Yes. Corrosion reduces efficiency by restricting water flow, insulating heat exchangers with sludge or scale, and forcing the boiler to work harder.

Is corrosion covered under boiler warranty?

Usually not. Manufacturers consider corrosion a maintenance issue and often exclude it unless caused by a manufacturing defect.

Can I check for corrosion myself?

You can look for obvious signs like leaks, discoloured radiator water, cold spots, or pressure drops. However, internal corrosion assessment must be handled by a Gas Safe engineer.

Stay warm, The Boilers2Go Team

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.