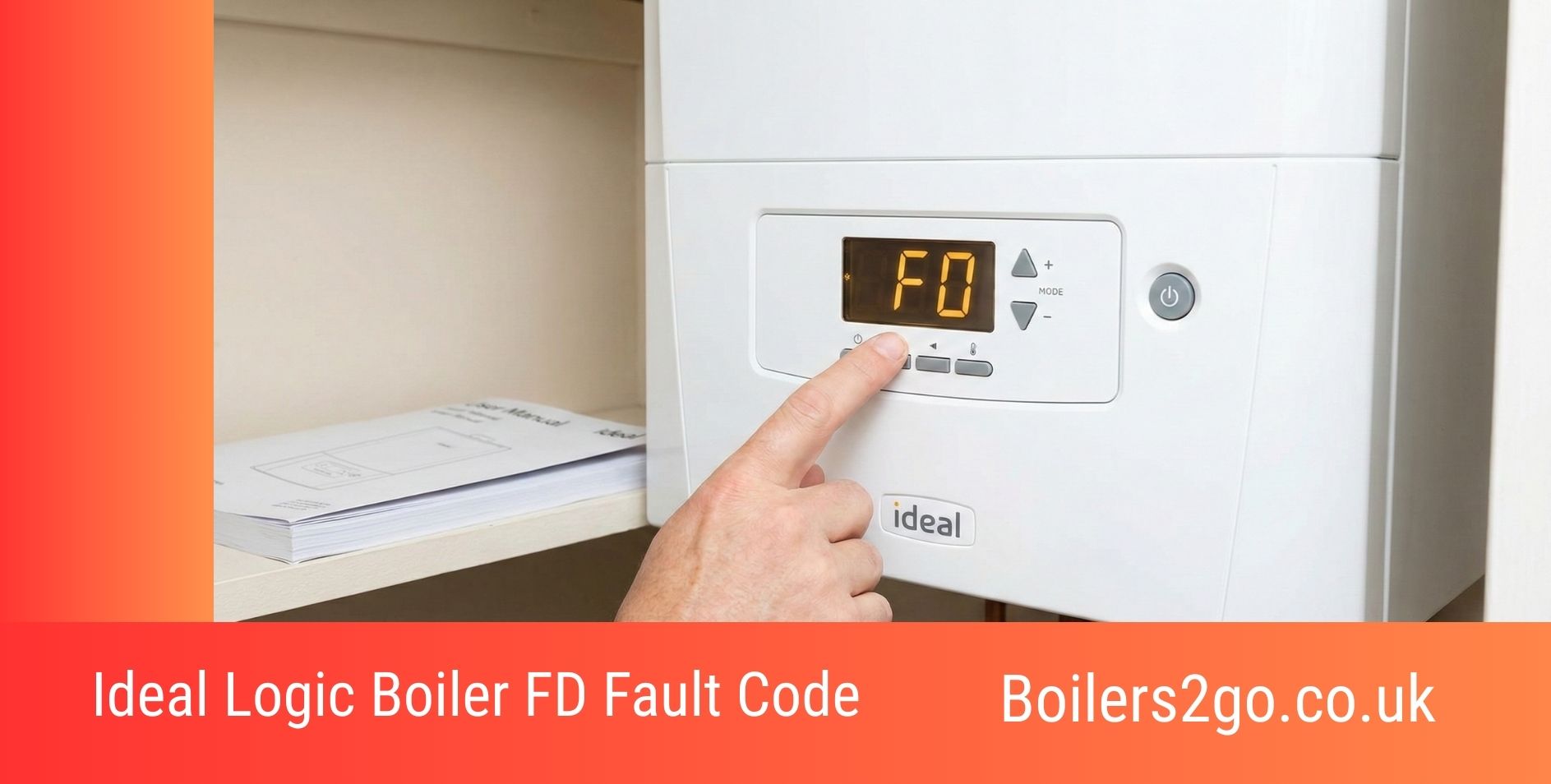

As someone who’s spent years in the trenches of the UK boiler world, I’ve encountered the Ideal Logic boiler FD fault code more times than I can count—it’s that pesky no-flow alert that grinds your heating to a halt just as the mercury drops.

If your boiler’s screen is flashing FD, it’s signalling a lack of water circulation, and in this guide, I’ll explain what it means, the usual suspects behind it, and hands-on fixes for each, all aimed at helping UK homeowners thaw out fast and landlords keep properties running smoothly.

What Does the Ideal Logic Boiler FD Fault Code Mean?

The Ideal Logic boiler FD fault code means your boiler has detected no water flow through the system, triggering a safety lockout to prevent overheating or damage.

In my experience with these combi and heat-only units, it’s the boiler’s built-in watchdog spotting insufficient circulation, often showing on the display to halt operation until resolved—think of it as a red flag for flow issues in your central heating setup.

Why This Code Appears

This error protects components like the heat exchanger from running dry, common in UK hard water areas where blockages build up over time.

What Causes the Ideal Logic Boiler FD Fault Code?

The causes of the Ideal Logic boiler FD fault code typically stem from disruptions in water movement or detection, leading to the boiler’s sensors crying foul. From countless diagnostics I’ve done, these often tie to maintenance lapses or installation quirks in British homes; here’s a closer look at the primary ones.

Low Water Pressure

Low water pressure happens when the system’s pressure drops below the ideal 1-1.5 bar, often from slow leaks, evaporation, or recent bleeding of radiators, preventing detectable flow.

How to Fix Low Water Pressure

- Check the pressure gauge on your boiler—if below 1 bar, locate the filling loop (usually flexible hoses under the unit).

- Slowly turn the valves to add mains water until the gauge hits 1.2 bar, with the system cold.

- Securely close the valves, reset the boiler by holding the reset button, and test heating.

- Monitor for drops; if it recurs, inspect for leaks or call a Gas Safe engineer.

Faulty Water Pressure Sensor

A faulty water pressure sensor occurs when the device gets clogged with debris or fails electrically, misreading flow even when pressure is adequate.

How to Fix Faulty Water Pressure Sensor

- Reset the boiler to clear any glitches—press and hold the reset for 5-10 seconds.

- Verify pressure manually; if stable but code persists, suspect the sensor.

- Engage a Gas Safe professional to clean or replace it, typically £100-£200 including checks.

- Pair with a system flush to avoid future clogs.

Blocked or Faulty Pump

A blocked or faulty pump develops from sludge accumulation or mechanical wear, where the pump runs but can’t push water effectively, mimicking no flow.

How to Fix Blocked or Faulty Pump

- Listen for unusual pump noises like humming; reset the boiler first.

- Bleed radiators to release air that might be impeding.

- Call a Gas Safe engineer for a pump inspection and replacement if needed, around £200-£400.

- Install a magnetic filter to catch debris long-term.

Air in the System

Air in the system builds up from installation, repairs, or poor bleeding, creating pockets that block water paths and trigger the no-flow detection.

How to Fix Air in the System

- Switch off the boiler and let it cool.

- Use a bleed key to vent each radiator, starting upstairs, until water flows steadily.

- Repressurise via the filling loop if pressure drops post-bleeding.

- Reset and test; if air returns, a pro might need to check for entry points.

Sludge Buildup in Pipes or Heat Exchanger

Sludge buildup in pipes or heat exchanger results from corrosion and minerals in UK water, restricting channels and reducing flow to undetectable levels.

How to Fix Sludge Buildup in Pipes or Heat Exchanger

- Add a chemical inhibitor to the system via a radiator for minor cases.

- Reset and monitor performance.

- Arrange a power flush by a Gas Safe specialist to clear heavy deposits, costing £400-£600.

- Maintain with annual dosing to prevent recurrence.

When Should You Get a New Boiler Quote?

If the FD fault keeps rearing its head after these tweaks, or your Ideal Logic is pushing 10+ years with waning efficiency, it’s a cue to explore replacements for hassle-free heating.

In my expert view, upgrading to a modern A-rated unit eliminates these flow frustrations, trimming bills and ensuring compliance. Request a free new boiler quote from Boilers 2 Go today!

FAQs

How does seasonal weather impact Ideal Logic FD faults in UK homes?

Cold snaps can exacerbate FD codes by contracting pipes or freezing components, reducing flow—pre-winter insulation and checks in exposed setups like attics help stave this off.

What warranty considerations apply to Ideal Logic boilers with FD errors?

Many Ideal warranties require proof of annual Gas Safe servicing to cover FD-related parts like sensors; documenting resets and fixes preserves your claim potential.

Are there smart add-ons for monitoring Ideal Logic FD precursors?

Compatible controls like Ideal’s Halo app can track pressure trends, alerting to drops before full FD lockouts in connected properties.

How often should landlords service Ideal Logic boilers to avoid FD?

Beyond yearly mandates, bi-annual pressure checks in tenant-heavy homes catch FD triggers like air ingress early, boosting reliability.

Can renewable links reduce FD frequency in Ideal Logic systems?

Integrating solar thermal eases demand on the pump, potentially lowering FD risks from overuse, but ensure pro compatibility assessments first.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.