The heat exchanger is one of the most important parts of your boiler. It’s the component that actually turns burning gas into usable heat for your radiators and hot water — without the water and gases ever mixing.

If your boiler were a car, the heat exchanger would be the engine block. When it’s working well, your heating feels effortless. When it starts to fail, problems quickly show up elsewhere in the system.

What a Heat Exchanger Does, in Simple Terms

Inside the boiler, gas is burned to create heat. That heat needs to be transferred into water safely and efficiently — and that’s exactly what the heat exchanger does.

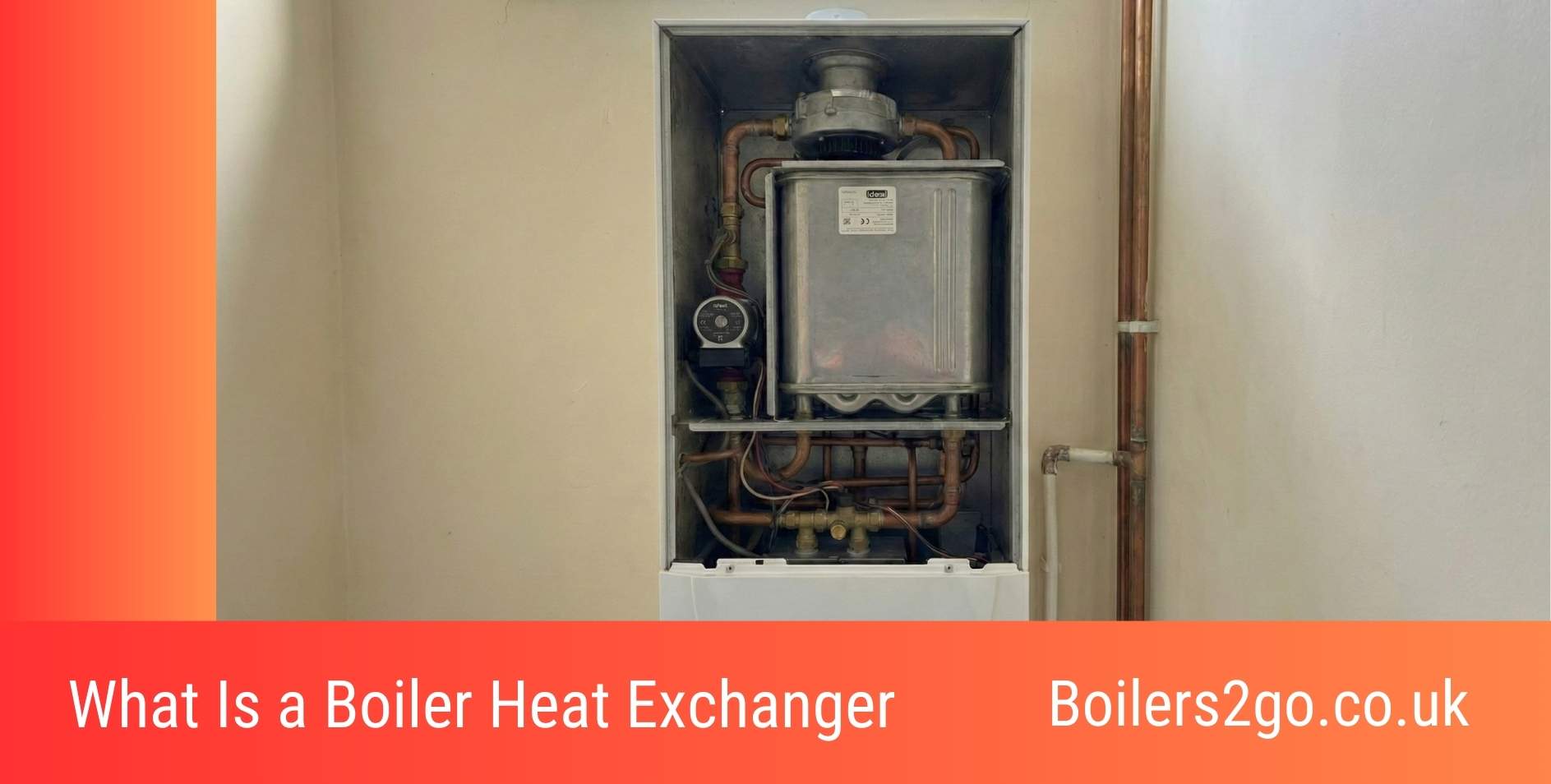

It’s made from shaped metal pipes or plates. Hot combustion gases pass over one side, while cold water flows through internal channels. Heat moves through the metal, warming the water, but the two never touch. This separation is vital for safety and efficiency.

Once heated, that water is sent around your radiators or to your taps, depending on what your boiler is being asked to do.

How the Heat Exchanger Works Day to Day

When you turn the heating on or open a hot tap, the boiler fires up. The burner ignites gas, heating the metal surfaces of the heat exchanger. Cold water flows through it, absorbs that heat, and leaves as hot water ready for use.

Most modern heat exchangers are made from stainless steel or aluminium, materials chosen because they handle high temperatures well and transfer heat efficiently. Older boilers sometimes used cast iron, but that’s far less common now due to weight and corrosion issues.

Primary vs Secondary Heat Exchangers (What’s the Difference?)

Not all boilers use just one heat exchanger.

Primary heat exchanger

The primary heat exchanger heats the water that circulates around your central heating system. That water flows through your radiators, returns to the boiler, and is reheated again and again.

Secondary heat exchanger

In combi boilers, there’s also a secondary (plate) heat exchanger. This is what provides instant hot water to your taps. It works by transferring heat from the primary system to fresh mains water — again, without the two ever mixing.

This setup allows combi boilers to deliver hot water on demand without storing it in a tank.

How Condensing Boilers Recover Extra Heat

Condensing boilers take things a step further.

After the primary heat exchanger has done its job, waste gases would normally exit through the flue. A condensing boiler captures extra heat from those gases using a secondary heat exchanger.

By cooling the exhaust gases below their dew point, water vapour condenses and releases additional “hidden” heat. That recovered heat is then used to pre-warm water returning to the boiler.

This process can improve efficiency by 10–12%, which is why modern condensing boilers achieve efficiency levels of up to 90–95% compared to older models.

Heat Exchanger Materials: Stainless Steel vs Aluminium

Most modern boilers use either stainless steel or aluminium heat exchangers. Both work well, but they behave differently over time.

Stainless steel heat exchangers

Stainless steel is highly resistant to corrosion across a wide range of water conditions. It’s durable, stable, and tends to last a long time with minimal issues.

The trade-off is cost and slightly slower heat transfer, but in real-world use this is rarely noticeable to homeowners.

Aluminium heat exchangers

Aluminium transfers heat extremely well and allows boilers to be compact, efficient, and lighter. It’s also cheaper to manufacture and recyclable.

However, aluminium is more sensitive to system water quality. Without proper treatment, sludge and incorrect pH levels can cause corrosion or efficiency loss over time.

How Long Do Heat Exchangers Last?

With good maintenance:

- Stainless steel heat exchangers often last 15–20 years or more

- Aluminium heat exchangers typically last 10–15 years, sometimes less if system water isn’t well maintained

The biggest factor isn’t the material — it’s how clean the heating system is.

How Sludge and Magnetite Cause Damage

Over time, corrosion inside radiators and pipework creates a black sludge called magnetite. This sludge circulates through the system and can cause serious problems inside the heat exchanger.

Aluminium exchangers are particularly vulnerable because they have narrower channels. Sludge restricts flow, creates hot spots, and forces the metal to overheat. Over time, this can lead to cracking, erosion, and reduced efficiency.

This is why filters, inhibitors, and regular servicing matter far more than most people realise.

Warning Signs of a Failing Heat Exchanger

Heat exchanger problems rarely appear out of nowhere. Common early signs include:

- Strange boiler noises like kettling, whistling, or rumbling

- Yellow or orange flames instead of a steady blue flame

- Uneven heating or hot water cutting in and out

- Rising gas bills without better heat output

- Water leaking inside the boiler casing

- Sooty marks, unusual smells, or carbon monoxide alarms activating

These symptoms can point to cracking, scaling, corrosion, or restricted flow — all issues that need professional attention.

Why Servicing Makes Such a Difference

During an annual boiler service, the engineer checks combustion, water quality, and heat transfer — all of which affect the heat exchanger.

Catching early signs of sludge buildup or corrosion can prevent costly repairs later. In many cases, simple maintenance steps extend the life of the heat exchanger by years.

The Big Picture

The heat exchanger is where your boiler’s efficiency, reliability, and safety all come together. Whether it’s stainless steel or aluminium, primary or secondary, its condition directly affects how well your heating and hot water perform.

Look after it, keep the system clean, and it will quietly do its job for years. Ignore it, and it’s often the component that turns a small issue into a major breakdown.

Does water hardness affect heat exchanger lifespan?

Yes. Hard water areas are more prone to limescale buildup inside the heat exchanger. Over time, scale acts as insulation, forcing the boiler to work harder and increasing the risk of overheating and damage.

Can low boiler pressure damage a heat exchanger?

Indirectly, yes. Low pressure can cause poor water circulation, leading to hot spots inside the heat exchanger. Repeated overheating and cooling stresses the metal and can shorten its lifespan.

Do system filters protect the heat exchanger?

They do. Magnetic system filters capture magnetite sludge before it reaches the heat exchanger, helping prevent blockages, overheating, and internal wear — especially important for aluminium exchangers.

Why does a heat exchanger fault sometimes cause a boiler to shut down?

Modern boilers have safety sensors that monitor temperature and flow. If the heat exchanger overheats or water flow is restricted, the boiler will shut down automatically to prevent damage or unsafe operation.

Are heat exchangers covered under boiler warranty?

Often yes, but coverage varies by manufacturer and model. Many warranties include the heat exchanger as a core component, provided the boiler is serviced annually and system water quality standards are met.

Can power flushing fix heat exchanger problems?

Power flushing can improve circulation and remove sludge, but it won’t repair a cracked or badly corroded heat exchanger. It’s preventative or supportive maintenance rather than a cure for structural damage.

Why do heat exchanger issues sometimes smell metallic or “hot”?

Overheating metal, burning dust, or minor leaks inside the boiler casing can create metallic or hot smells. While not always dangerous, these smells should always be checked by an engineer.

Does using smart heating controls reduce heat exchanger wear?

Yes. Smarter controls reduce unnecessary boiler cycling, which lowers thermal stress on the heat exchanger and can help extend its working life over time.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.