As a UK homeowner or landlord, few things are more frustrating than a central heating system that lets you down on a chilly winter evening.

If you’re staring at a flashing display on your Baxi boiler showing one of those cryptic Baxi boiler error codes, you’re not alone—thousands search for “Baxi boiler error codes” each month hoping for a quick diagnosis and fix.

These fault indicators are your boiler’s way of communicating a problem, whether it’s a simple pressure drop or a more complex ignition issue.

In this guide, I’ll break down the most common Baxi boiler fault codes, explain what they mean, discuss the root causes behind them, and provide step-by-step fixes tailored for everyday users like you.

From combi models like the EcoBlue to system boilers such as the Duo-tec, we’ll cover it all, helping you decide if it’s a DIY task or time to call in a Gas Safe registered engineer.

Remember, while some Baxi heating system errors can be resolved at home, safety always comes first—especially when dealing with gas appliances.

Most Common Baxi Boiler Error Codes

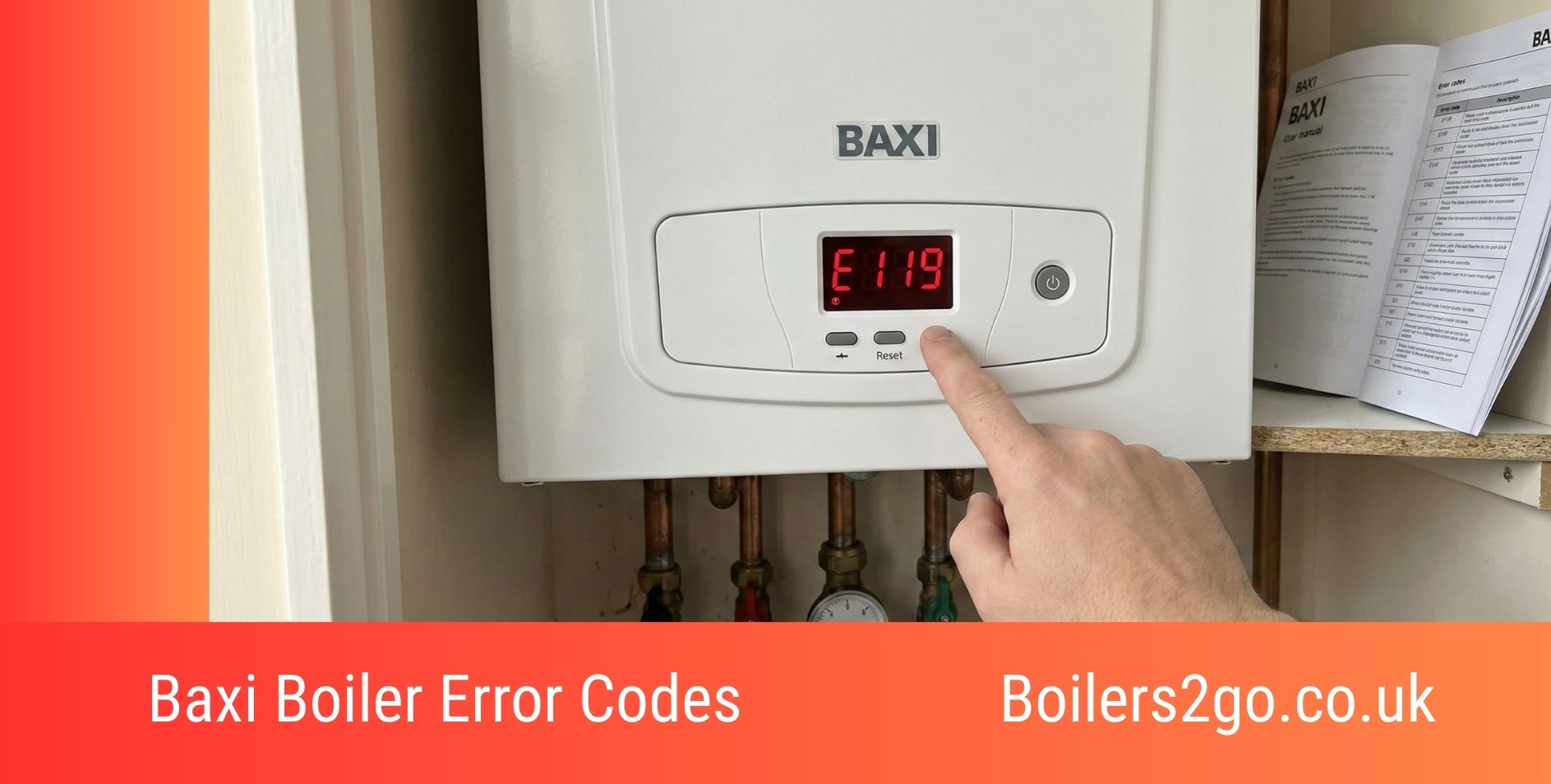

E119 Error Code Mean

The E119 error code on a Baxi boiler indicates critically low water pressure in the heating system, dropping below 0.5 bar, which prevents the boiler from firing up and circulating hot water effectively. To resolve the baxi boiler e119 fault code, it is essential to check the pressure gauge and ensure that the water pressure is restored to the recommended level, typically between 1 and 1.5 bar. In some cases, you may need to locate and fix any leaks in the system that could be contributing to the low water pressure. Once resolved, resetting the boiler may also be necessary to clear the error and allow the system to function properly again. If the low water pressure is not the issue, other faults may arise, such as the e160 Baxi boiler error code, which signifies a different problem within the system. In such cases, inspecting the user manual for e160 Baxi boiler error code solutions can provide guidance on diagnosing and addressing the underlying issues. Regular maintenance and timely repairs can prevent these error codes from appearing and ensure optimal boiler performance.

This fault locks out the appliance to avoid dry running, which could damage internal parts like the heat exchanger. In UK homes, where sealed systems rely on consistent pressure (ideally 1-1.5 bar when cold), an E119 alert often leaves radiators cold and taps running tepid, disrupting daily routines for families or tenants.

What Causes the E119 Error Code?

The E119 error code is primarily caused by insufficient water in the closed-loop central heating circuit, but several underlying factors can trigger this drop.

Cause 1: Natural Pressure Loss Over Time

In sealed Baxi heating systems, microscopic evaporation or air ingress causes gradual pressure decline, especially in older installations without automatic fill valves.

How to Fix It

- Monitor the pressure gauge weekly; if below 1 bar, use the filling loop (a flexible hose connecting cold mains to the boiler) to top up.

- Turn the isolation valves 90 degrees to allow flow, watch the gauge rise to 1.2 bar, then close.

- Bleed radiators to release trapped air, recheck after 30 minutes. For landlords, schedule quarterly checks to catch this early.

Cause 2: A Small Leak in the System

Drips from radiator valves, pipe joints, or the boiler itself erode pressure, common in properties with hard water scale buildup. These leaks can lead to significant heat loss and increased energy bills, as your heating system works harder to maintain the desired temperature. Regular maintenance is essential to prevent these issues and ensure optimal performance, resulting in no hot water issues for your household. Additionally, addressing hard water scale buildup can prolong the life of your boiler and heating system, making it wise to invest in a water softener if needed.

How to Fix It

- Inspect visible pipes and radiators for damp spots or corrosion; tighten loose fittings with a spanner if accessible.

- For hidden leaks, apply soapy water to suspect joints—bubbles indicate escapes. Isolate the system, drain via the lowest radiator, and repressurise.

- If persistent, trace with a moisture meter or call a plumber to pressure-test the entire network.

Cause 3: Faulty Pressure Relief Valve

A stuck or worn pressure relief valve (PRV) on the boiler discharges water automatically, mimicking a leak and triggering E119.

How to Fix It

- Locate the PRV (usually on the boiler’s outlet pipe) and check for discharge pipe wetness. Gently lift the valve lever to test—water should flow freely then stop.

- If it drips continuously, replace the valve cartridge (a brass component inside); this requires draining the system first.

- Always test post-fix by running the boiler and monitoring for 24 hours.

E133 Error Code Mean

The E133 error code signals a failure to detect the burner flame after ignition attempts, halting gas flow to prevent unsafe operation in your Baxi boiler. This lockout protects against incomplete combustion, which could lead to soot buildup or incomplete burns in the heat exchanger.

Homeowners often notice this during startup, with the boiler clicking repeatedly but producing no heat, a frequent winter woe in unheated UK properties.

What Causes the E133 Error Code?

Ignition and flame detection issues drive the E133 code, often linked to supply disruptions or component wear in gas-fired boilers.

Cause 1: Frozen Condensate Pipe

In sub-zero temperatures, the external plastic drain pipe for acidic condensate freezes solid, backing up the system and extinguishing the flame.

How to Fix It

- Identify the white/grey 22mm pipe exiting your boiler to the drain. Wrap it in lagging foam or heat tape (available at DIY stores for £10-15).

- For immediate thaw, pour warm (not boiling) water over the frozen section or use a hairdryer on low for 10-15 minutes.

- Ensure the pipe slopes downward to avoid future sags; secure with clips if needed. Test by resetting the boiler—hot water should resume within minutes.

Cause 2: Interrupted Gas Supply

A closed meter valve, depleted prepay credit, or supplier outage starves the burner of natural gas, mimicking a flame failure.

How to Fix It

- Verify your gas meter shows credit (top up via app if smart) and the emergency control valve (ECV) near the meter is parallel to the pipe.

- Sniff for gas odours—if present, evacuate and call the National Gas Emergency line (0800 111 999).

- For blockages, gently tap the meter to dislodge debris, then reset. If supply resumes but E133 persists, check internal valves.

Cause 3: Faulty Ignition Electrode or Lead

The spark electrode, which senses and ignites the flame, corrodes or its wiring frays over time, failing to register combustion.

How to Fix It

- Power off at the fused spur, remove the boiler front panel (screws at base), and locate the porcelain-tipped electrode near the burner.

- Clean carbon deposits with fine sandpaper, ensuring the gap is 3-4mm. Inspect leads for cracks—splice if minor, but replace the assembly (£20-40 part) if damaged.

- Reassemble, reset, and run a cycle; professional calibration may be needed for precise alignment.

E110 Error Code Mean

The E110 error code denotes primary heat exchanger overheating, where the boiler’s core temperature exceeds safe limits (around 85°C), triggering a shutdown to avert scalding or warping. This fault disrupts both heating and hot water, often with gurgling sounds, and is prevalent in Baxi system boilers with sludge accumulation.

What Causes the E110 Error Code?

Overheating in the E110 code arises from circulation blockages or pump inefficiencies, impeding heat dissipation.

Cause 1: Air Trapped in the Radiator Circuit

Air pockets from improper bleeding create hot spots, slowing water flow and causing localised overheating.

How to Fix It

- Turn off the boiler, attach a radiator key to the top bleed valve on each unit, and release air until water trickles out (place a cloth underneath).

- Start from the lowest floor, working up. Refill via the filling loop to 1.5 bar, then run the pump override (if available) for 5 minutes to circulate.

- Monitor for recurrence—add a chemical inhibitor if air returns frequently.

Cause 2: Pump Failure or Airlock

The circulating pump seizes or cavitates due to air, failing to push water through the heat exchanger.

How to Fix It

- Listen for the pump hum behind the boiler; if silent or humming without flow, isolate electrically and manually spin the pump shaft (via front cover slot) with a screwdriver—lubricate with a drop of oil if stiff.

- Bleed the pump’s air screw if present.

- For seized motors, replace the pump head (£100-150); test flow by checking radiator warmth post-reset.

Cause 3: Sludge Buildup in Pipes

Magnetite sludge from rust clogs narrow pipes, restricting flow and trapping heat in the exchanger.

How to Fix It

- Flush the system with a power flush (rent a machine for £50/day) by connecting to the lowest drain point, running hot water with a descaler additive for 1-2 hours.

- Isolate zones via valves to target radiators.

- Follow with inhibitor addition via the header tank or filling loop. For severe cases, a pro flush prevents recurrence.

E168 Error Code Mean

The E168 error code is a generic “ignition or communication fault,” where the printed circuit board (PCB) detects an unspecified electrical or control issue, often after power surges. It manifests as erratic operation or total lockout, puzzling for non-experts managing Baxi combi units in rented flats.

What Causes the E168 Error Code?

Electrical glitches underpin the E168 code, from transient errors to hardware degradation.

Cause 1: Temporary Power Fluctuation

Voltage dips from tripped breakers or grid instability confuse the PCB, logging a false positive.

How to Fix It

- Reset the boiler by pressing the reset button (or power cycle via the wall switch for 30 seconds).

- Check your consumer unit for partial trips—flip breakers off/on. Install a surge protector (£20) on the boiler spur to buffer future spikes.

- Run a test cycle; if stable, log the event for warranty claims.

Cause 2: Wiring Loose Connection

Vibration or age loosens terminals on sensors or the gas valve, interrupting signals.

How to Fix It

- With power off, inspect the PCB (green board inside) for loose plugs—gently reseat them. Use a multimeter to test continuity on suspect wires (0 ohms = good).

- Tighten screws on connectors.

- Avoid soldering unless qualified; photograph before disassembly for reassembly.

Cause 3: Faulty PCB or Sensor

Degraded electronics on the main board or a shorted thermistor send erratic data, defaulting to E168.

How to Fix It

Diagnose by swapping accessible sensors (e.g., NTC thermistor—£15 part) and testing resistance (10k ohms at 25°C). PCBs require pro replacement (£200+ labour included) due to programming. Back up settings if possible; post-fix, update firmware via Baxi app if your model supports it.

E160 Error Code Mean

The E160 error code points to a fan speed anomaly, where the extraction fan runs too slow, fast, or not at all, compromising flue gas venting and risking unsafe indoor air. Critical for Baxi boilers with balanced flues, this halts operation to comply with Building Regulations Part J.

What Causes the E160 Error Code?

Fan discrepancies in E160 often result from mechanical or electrical hindrances.

Cause 1: Blocked Flue Terminal

Bird nests, leaves, or ice obstruct the external vent, impeding airflow.

How to Fix It

- Safely access the roof or wall terminal (use a ladder securely), remove debris with gloves and a brush.

- Ensure 1m clearance from obstacles per Baxi specs.

- Vacuum internals if accessible. Test fan spin-up on reset—audible whir confirms clearance.

Cause 2: Dirty or Worn Fan Blades

Dust accumulation or bearing wear reduces RPM, triggering the tachometer sensor.

How to Fix It

- Isolate power, remove the fan assembly (usually four screws), and clean blades with a soft brush and compressed air. Lubricate bearings if oiled ports exist.

- For wear, replace the fan module (£80-120). Align precisely during reinstall to avoid vibration.

Cause 3: Electrical Supply to Fan

Loose wiring or a blown fuse cuts power to the fan motor.

How to Fix It

- Check the inline fuse (3A glass type on the PCB) for continuity—replace if black.

- Trace wires from PCB to fan for frays; strip and reconnect with crimps.

- Use a multimeter for 230V AC at the fan terminals during startup. If absent, trace back to the control relay.

How Can I Prevent Baxi Boiler Error Codes in the Future?

Preventing Baxi boiler error codes involves proactive maintenance to keep your central heating system robust against common UK pitfalls like limescale and frost.

Schedule an annual Gas Safe service to inspect components, flush sludge, and calibrate sensors—vital for warranty validity and efficiency under the Boiler Plus regulations. Insulate pipes and the condensate drain with foam lagging to thwart freezing, and fit an external frost stat for automatic protection. Additionally, consider upgrading your heating system with new boiler installation services to enhance energy efficiency and reliability. Regular maintenance not only prolongs the life of your system but also ensures that it operates at peak performance during colder months. Staying ahead of potential issues can save on costly repairs and keep your home comfortable year-round.

For pressure stability, install auto-fill valves and monitor via smart apps like Baxi’s uSense. Landlords should log services for compliance, while homeowners benefit from weekly gauge checks and inhibitor top-ups. These steps not only dodge faults but slash energy bills by up to 10%, ensuring reliable hot water and radiator warmth year-round.

When You Absolutely MUST Call a Gas Safe Engineer

While minor tweaks like repressurising can resolve some Baxi boiler faults, certain scenarios demand immediate intervention from a Gas Safe registered engineer to avert dangers like gas leaks or explosions.

Call without delay if error codes recur after resets, accompany gas smells, soot marks, or yellow flames—hallmarks of combustion issues. Electrical faults (E168/E160) involving PCBs or fans require certified handling due to live wires, and any suspected leaks (beyond visible drips) need leak detection tools.

For landlords, persistent codes breaching tenant comfort levels trigger legal duties under the Homes (Fitness for Human Habitation) Act. Prioritise pros for part replacements like electrodes or valves, as DIY mishaps void warranties and risk fines. Search the Gas Safe Register online for verified experts—better safe than sorry in your home heating setup.

FAQs

How Often Should I Service My Baxi Boiler to Avoid Error Codes?

Annual servicing by a Gas Safe engineer is recommended for Baxi boilers, but in hard water areas like the South East, consider biannual checks to prevent scale-related faults. This includes a full system flush and component test, catching issues before they trigger codes.

Can Weather Conditions Trigger Specific Baxi Boiler Faults?

Yes, UK winters often spark E133 from frozen pipes, while summer droughts might cause pressure drops in E119 due to evaporation. Installing weather-compensating controls can mitigate these seasonal central heating disruptions.

What’s the Difference Between Temporary and Permanent Baxi Error Codes?

Temporary codes, like some E168 instances, clear after a reset and indicate fleeting glitches, whereas permanent ones (e.g., repeated E160) signal hardware failure needing replacement. Always log occurrences to track patterns.

Do Baxi Boiler Error Codes Vary by Model, Like Combi vs System?

Absolutely—combi models like the EcoBlue emphasise hot water flow codes (E119 frequent), while system boilers like Duo-tec highlight pump issues (E110). Consult your model’s manual for tailored diagnostics.

Is There a Mobile App for Monitoring Baxi Boiler Faults?

Baxi’s myBaxi app connects compatible models for real-time alerts on potential errors, pressure readings, and service reminders, helping UK users preempt breakdowns remotely.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.