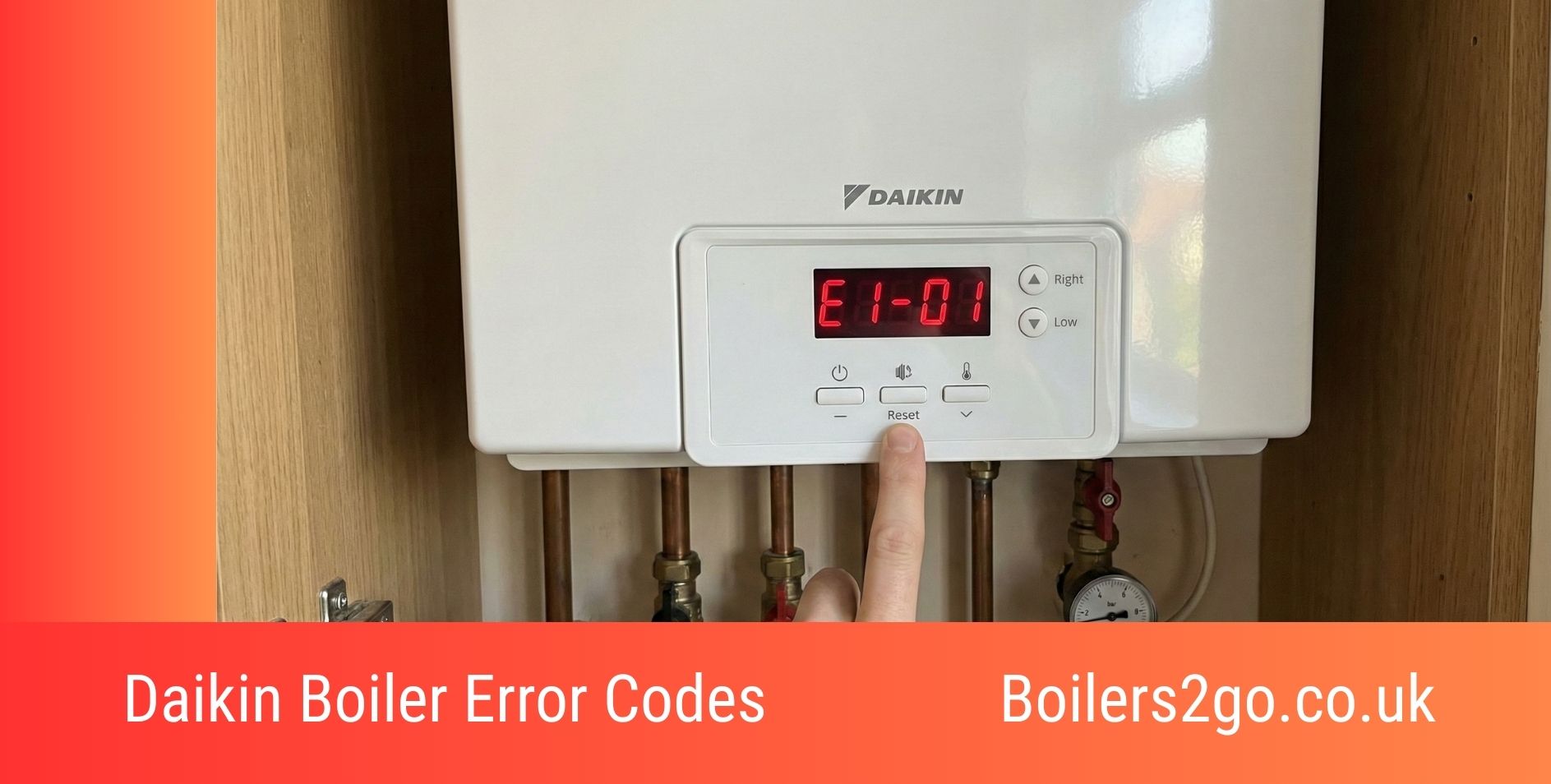

Daikin boiler error codes are a common sight when something’s amiss with your home heating system. These diagnostic fault indicators, often displayed as alphanumeric sequences like U4 or HJ-08, act as your boiler’s way of communicating issues, from minor glitches to more serious central heating faults.

Understanding these error codes can help you troubleshoot quickly, potentially saving on emergency call-outs and keeping your radiators hot without unnecessary stress.

In this guide, I’ll break down the most frequent Daikin boiler fault codes, root causes, and step-by-step fixes tailored for everyday users.

Remember, while many Daikin heating system problems can be resolved at home, safety always comes first—especially with gas appliances.

What Are the Most Common Daikin Boiler Error Codes?

The most common Daikin boiler error codes typically point to everyday issues in UK homes, such as pressure imbalances or sensor hiccups, affecting models like the Daikin Opopure or Altherma hybrid systems. These central heating error messages help pinpoint boiler malfunctions before they escalate into full breakdowns.

U4 Daikin Boiler Error Code

The U4 Daikin boiler error code signals a communication breakdown between the main control board and other components in your heating system, often halting hot water flow or radiator output entirely.

What Causes the U4 Error Code?

This fault usually stems from electrical or wiring disruptions in the Daikin boiler’s internal network. Key triggers include:

- Loose or Corroded Wiring Connections: Over time, vibrations from the boiler’s operation or damp conditions in UK lofts can loosen wires, interrupting signals between the printed circuit board (PCB) and sensors.

- Faulty Control Board: The PCB, the boiler’s “brain,” might fail due to power surges or age, common in older installations.

- External Interference: Rarely, issues with linked devices like smart thermostats can mimic this code.

How to Fix the U4 Error Code

For Loose or Corroded Wiring Connections:

- Start by isolating the boiler—turn off the power at the fused spur and the gas supply for safety.

- Open the boiler casing (consult your user manual for model-specific access) and visually inspect visible wiring harnesses for fraying or green corrosion.

- Gently unplug and replug connectors, wiping them with a dry cloth. If corrosion is present, use a mild electrical contact cleaner (available at DIY stores like B&Q).

- Reassemble, restore power, and reset the boiler by pressing the reset button for 5 seconds. Test by running hot water; if the code clears, monitor for recurrence.

For Faulty Control Board:

A PCB replacement isn’t a DIY job due to the risk of electrical shock. Note the model number and contact a Gas Safe registered engineer via Daikin’s service line (0333 241 9999) or a local installer. Expect costs around £200–£400, including labour, but it’s essential for restoring reliable home heating.

For External Interference:

Disconnect any external controls, like a Honeywell Evohome thermostat, and reset the boiler. If the error vanishes, reconnect one device at a time to isolate the culprit, then check compatibility in your Daikin manual.

E3 Daikin Boiler Error Code

An E3 Daikin boiler error code indicates an air lock or flow restriction in the heating circuit, preventing proper water circulation and causing uneven radiator temperatures or no heat at all.

What Causes the E3 Error Code?

This code often arises from trapped air or blockages disrupting the boiler’s water flow, a frequent issue in UK properties with older pipework.

- Trapped Air in Radiators or Pipes: Air enters the system during bleeding or low-pressure periods, blocking hot water movement.

- Blocked Heat Exchanger: Limescale buildup in hard water areas (common in the South East) or sludge from neglected maintenance clogs the exchanger.

- Pump Failure: The circulation pump might seize due to wear, reducing flow rates below the boiler’s threshold.

How to Fix the E3 Error Code

For Trapped Air in Radiators or Pipes:

- Bleed each radiator starting from the highest point in your home—use a radiator key to open the valve until water (not air) flows, catching drips in a cloth.

- Top up system pressure to 1–1.5 bar via the filling loop (cold mains tap connected to the boiler).

- Reset the boiler and run the heating for 15 minutes to purge remaining air. This simple fix often resolves the issue without tools beyond basics.

For Blocked Heat Exchanger:

- Flush the system using a magnetic system cleaner like Fernox F3, added via a radiator.

- Run the boiler on a high setting for an hour, then drain and refill.

For severe blockages, a power flush by a professional (around £300–£500) is needed to avoid damaging the heat exchanger, ensuring long-term efficiency in your central heating setup.

For Pump Failure:

Listen for unusual humming from the pump during operation. If silent or vibrating excessively, it may need replacing. Shut off power and gas, then have a Gas Safe engineer assess—pump swaps cost £150–£250 and restore flow quickly.

HJ-08 Daikin Boiler Error Code

The HJ-08 Daikin boiler error code denotes high water pressure in the heating system, which can strain components and trigger a safety lockout, leaving your home cold.

What Causes the HJ-08 Error Code?

Excess pressure builds when the system’s equilibrium is upset, often in sealed combi boilers common in UK semis and terraces.

- Faulty Pressure Relief Valve: This safety valve sticks open or closed, failing to release excess pressure.

- Expansion Vessel Issues: The vessel’s diaphragm ruptures or air charge depletes, causing unchecked water expansion when heated.

- Overfilling During Maintenance: Incorrectly topping up pressure beyond 1.5 bar during bleeding.

How to Fix the HJ-08 Error Code

For Faulty Pressure Relief Valve:

- Locate the valve on the boiler’s outlet pipe and attach a hose to its drain, directing water safely outside.

- Briefly open to release pressure down to 1 bar, then close.

If it leaks continuously, replacement is required—call a Gas Safe pro for this, as it involves depressurising the system safely (labour around £100–£200).

For Expansion Vessel Issues:

- Check the vessel’s air valve with a pressure gauge; it should read 0.75 bar when cold. If low, repressurise with a bike pump.

- For a ruptured diaphragm (water spurts from the valve), full replacement costs £150–£300 and prevents recurring high-pressure faults in your home heating.

For Overfilling During Maintenance:

Use the boiler’s pressure gauge to bleed excess via the relief valve as above, then adjust to 1–1.2 bar cold. Avoid future overfills by using a digital manometer for accuracy during DIY tasks.

What Are Other Notable Daikin Boiler Fault Codes?

Beyond the everyday culprits, other Daikin boiler fault codes like U8 or AA can signal deeper issues in your heating installation, from ignition failures to hybrid system mismatches.

U8 Daikin Boiler Error Code

A U8 Daikin boiler error code means low water pressure in the primary circuit, starving the boiler of flow and risking dry-run damage.

What Causes the U8 Error Code?

Pressure drops due to leaks or natural dissipation in sealed systems.

- System Leaks: Dripping joints or radiator valves in older UK homes.

- Filling Loop Fault: The loop’s non-return valve sticks, preventing repressurisation.

How to Fix the U8 Error Code

For System Leaks: Inspect visible pipes and radiators for damp spots; tighten fittings or use PTFE tape on threads. For hidden leaks, add inhibitor and monitor—persistent issues need a leak detection service (£200+).

For Filling Loop Fault: Clean or replace the valve; open the loop slowly to reach 1 bar, ensuring no water backflow.

AA Daikin Boiler Error Code

The AA Daikin boiler error code, common in Altherma air source heat pump hybrids, flags a sensor or activation fault, often no hot water.

What Causes the AA Error Code?

Mismatched components or environmental factors.

- Sensor Wiring Damage: Rodent chews or wear in loft installations.

- Low Refrigerant: In hybrid setups, leaks reduce efficiency.

How to Fix the AA Error Code

For Sensor Wiring Damage: Inspect and repair/replace wires; reset to test.

For Low Refrigerant: Mandatory professional recharge—F-Gas certified engineer required (£300–£600).

How to Prevent Daikin Boiler Error Codes in the Future

Preventing Daikin boiler error codes starts with proactive home heating maintenance, tailored for busy UK homeowners and landlords managing rental properties.

Schedule an annual Gas Safe service to catch pressure anomalies or wiring wear early—costs £80–£120 but avoids £500+ breakdowns.

Install a magnetic filter to trap sludge, reducing blockages by 70%, and use inhibitor fluid yearly to combat limescale in hard water regions. For landlords, fit frost protection on vacant properties and educate tenants on basic checks like monthly pressure reads (aim for 1–1.5 bar).

Smart thermostats compatible with Daikin, like the Daikin Online Controller app, alert you to anomalies via your phone, ensuring efficient central heating year-round. Regular bleeding and avoiding DIY overpressurising keep faults at bay, extending your boiler’s 10–15-year lifespan.

When You Absolutely MUST Call a Gas Safe Engineer

While many Daikin boiler error codes allow safe DIY diagnostics, certain scenarios demand immediate professional intervention to comply with UK gas safety regulations and prevent hazards like carbon monoxide leaks.

Always call a Gas Safe registered engineer if the fault involves gas supply disruptions (e.g., no ignition on U9 codes), persistent leaks, or electrical work like PCB swaps—these risk explosions or shocks.

For hybrid Altherma systems showing refrigerant errors (AA or U0), F-Gas certification is legally required..

Delaying can void warranties and lead to fines—better safe than sorry for your family’s warmth.

FAQs

How often should I check my Daikin boiler’s pressure to avoid error codes?

Maintaining optimal pressure between 1 and 1.5 bar when cold helps prevent codes like U8 or E3. For UK homes, inspect monthly during heating season and after long off-periods, using the built-in gauge—it’s a quick 2-minute task that can flag slow leaks early.

Can weather conditions trigger specific Daikin boiler error codes?

Yes, freezing UK winters often provoke U4 or E1 codes from frost-induced sensor errors. Enabling the boiler’s built-in frost protection mode (set to activate above 5°C) mitigates this, especially for unheated holiday homes or rental flats.

What’s the difference between Daikin combi boiler error codes and those on hybrid models?

Combi units like the Opopure focus on pressure/flow codes (e.g., HJ-08), while Altherma hybrids add refrigerant-related faults like AA due to their air source integration. Always cross-reference your model’s manual for precise diagnostics.

Do Daikin boiler error codes reset automatically after fixing the issue?

Most do after a power cycle or manual reset, but persistent codes like U8 may require holding the reset button for 5–10 seconds. If it recurs within 24 hours, log the pattern for your engineer—it speeds up hybrid system troubleshooting.

Are Daikin boiler error codes covered under warranty?

Standard 5–7 year warranties cover manufacturing faults triggering codes, but neglect (e.g., unserviced blockages) voids them. Register your installation promptly and keep service records to claim free repairs on eligible central heating issues.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.