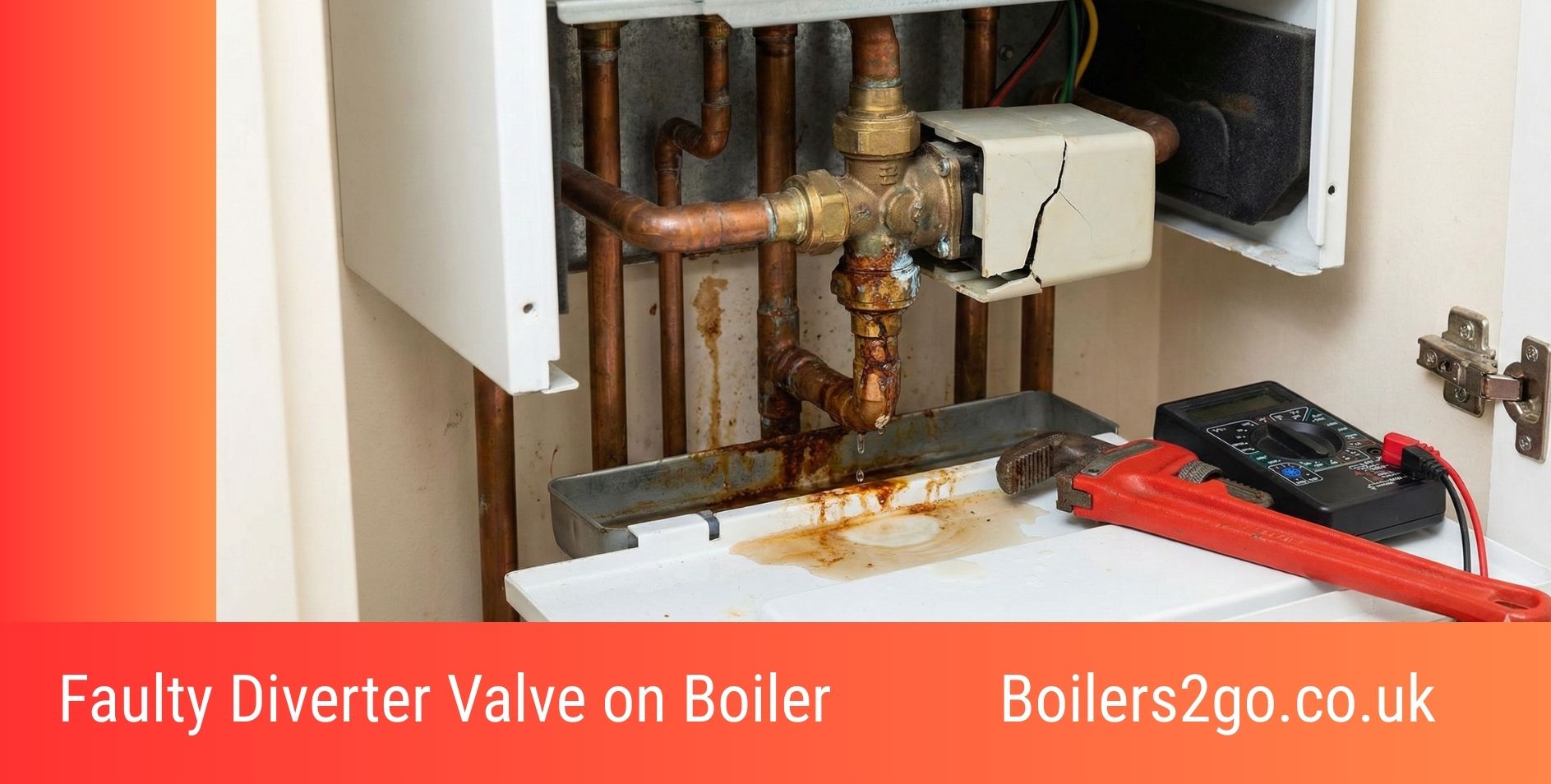

A faulty diverter valve on a boiler is one of the most common reasons UK homeowners suddenly lose hot water, get lukewarm radiators, or find the heating and hot water working at the same time.

This small but critical component decides whether hot water from the boiler goes to your taps and showers (hot water mode) or to your central heating system (heating mode). When it fails, you’ll quickly notice the problem – and often see a fault code on the boiler display.

In this guide, I’ll explain exactly what a diverter valve does, the specific causes of a faulty diverter valve on a boiler, how to diagnose it, and step-by-step ways to fix each cause.

What is a Diverter Valve in a Combi Boiler?

A diverter valve in a combi boiler is a motorised valve (sometimes called a mid-position valve or 3-port valve in system boilers) that “diverts” hot water to either the central heating circuit or the domestic hot water heat exchanger.

In simple terms, it acts like a set of railway points – it physically moves to send hot water in the right direction depending on what you’ve asked for (heating, hot water, or both on some boilers).

Most modern combi boilers use a 3-way diverter valve powered by a small electric motor and sometimes helped by a wax capsule or diaphragm.

What Are the Common Symptoms of a Faulty Diverter Valve?

A faulty diverter valve on a boiler usually shows itself in one (or more) of these ways:

- Hot water works but central heating doesn’t (or is very slow to warm up)

- Central heating works but no hot water at the taps

- Radiators get hot when you only run hot water (and vice versa)

- Lukewarm water at the taps even when the boiler temperature is set high

- The boiler locks out and displays a fault code (common codes below)

- Unusual banging or humming noises from the boiler when switching between modes

Common fault codes linked to a diverter valve problem:

- Vaillant – F28, F75 (sometimes)

- Worcester Bosch – EA 227, D1 286

- Ideal – F1, L2, L6

- Baxi / Potterton – E133, E160, E168

- Glow-worm – F22, F75

What Causes a Faulty Diverter Valve on a Boiler?

Cause 1: The Diverter Valve Motor Has Failed

The diverter valve motor is the most common part to fail after 8–15 years. The little electric actuator burns out or the gears inside strip.

How to fix a failed diverter valve motor

In most boilers (Worcester, Vaillant, Baxi, Ideal, Glow-worm, etc.) you can replace just the motor head without draining the entire system.

- Turn off power to the boiler.

- Remove the front cover and locate the diverter valve (usually on the right-hand side).

- Unplug the electrical connector and undo the two or three fixing screws.

- Lift off the old motor and fit the new one (they clip straight on).

- Reconnect and test. Cost: £45–£90 + labour. Many Gas Safe engineers keep common motors in the van.

Cause 2: Stuck or Seized Diverter Valve Spindle

Limescale, magnetite sludge and general debris can jam the valve spindle so it won’t move fully between positions.

How to fix a stuck or seized diverter valve spindle

- Option A (temporary): Gently tap the valve body with a soft hammer or the handle of a screwdriver while switching between heating and hot water – this sometimes frees it.

- Option B (proper fix): Fit a full diverter valve cartridge or complete new valve assembly. On Worcester and Vaillant boilers this is a 10–15 minute job for a pro because the cartridge simply pulls out once two clips are released. Cost: £120–£220 for the full valve kit + labour.

Cause 3: Torn or Perished Diaphragm / Wax Capsule

Older style diverter valves (common on Potterton, Baxi and some Ideal Logic boilers) use a rubber diaphragm or wax capsule to help move the valve. These perish over time.

How to fix a torn diaphragm or failed wax capsule

The only fix is replacement of the complete diverter valve assembly. The diaphragm itself is not sold separately on most modern boilers.

Cause 4: Faulty Microswitch or PCB Communication Issue

The microswitch tells the printed circuit board (PCB) that the valve has reached the correct position. If the switch fails, the boiler thinks the valve is stuck and locks out.

How to fix a faulty microswitch

A Gas Safe engineer will test with a multimeter and either replace the switch (£15–£30) or the whole valve head if the switch is built in.

Cause 5: Airlock or System Pressure Problems Mimicking a Diverter Valve Fault

Very low system pressure or an airlock can stop the valve moving properly.

How to fix low pressure or airlock issues

- Check the pressure gauge is between 1–1.5 bar when cold.

- Top up via the filling loop if needed.

- Bleed radiators and the pump to remove air. This is a DIY job for most homeowners.

How to Prevent Diverter Valve Problems in the Future

- Annual boiler service – a Gas Safe engineer will clean and check the valve operation.

- Install (or service) a magnetic system filter (Magnaclean, Fernox TF1, etc.) to catch sludge before it reaches the valve.

- Use quality inhibitor (Fernox F1 or Sentinel X100) and top up every year.

- Keep system pressure correct – low pressure causes extra wear on the motor.

- In hard water areas, fit a scale reducer or water softener to reduce limescale build-up.

When You Absolutely MUST Call a Gas Safe Engineer

You must call a Gas Safe registered engineer immediately if:

- You smell gas at any point.

- The boiler is leaking water.

- You see any fault code and have no heating or hot water in winter.

- You’re unsure about any repair – working on the gas side of a diverter valve is illegal for non-qualified people.

- The boiler is still under manufacturer warranty (DIY repair voids it).

Never attempt to dismantle sealed gas-carrying parts yourself.

FAQs

How long should a diverter valve last on a UK combi boiler?

Most quality diverter valves last 10–15 years with annual servicing. In hard-water areas or unfiltered systems they can fail in as little as 6–8 years.

Can a faulty diverter valve cause high gas bills?

Yes – if the valve is stuck in “mid position” the boiler keeps firing to try and satisfy both heating and hot water demands at the same time, wasting gas.

Is it worth repairing an old diverter valve or should I replace the whole boiler?

If the rest of the boiler is in good condition and under 12–14 years old, repairing the diverter valve is nearly always cheaper than a new boiler (£600–£900 repair vs £2,500+ new boiler).

Will a powerflush fix my stuck diverter valve?

A powerflush can free a lightly seized valve, but if it’s heavily scaled or the motor has failed, the valve will still need replacing.

Are some boiler brands more prone to diverter valve problems?

Worcester-Bosch and Vaillant have excellent reputations for reliable diverter valves. Some older Baxi, Potterton and Glow-worm models from the 2000s–early 2010s were more prone to early failure.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.