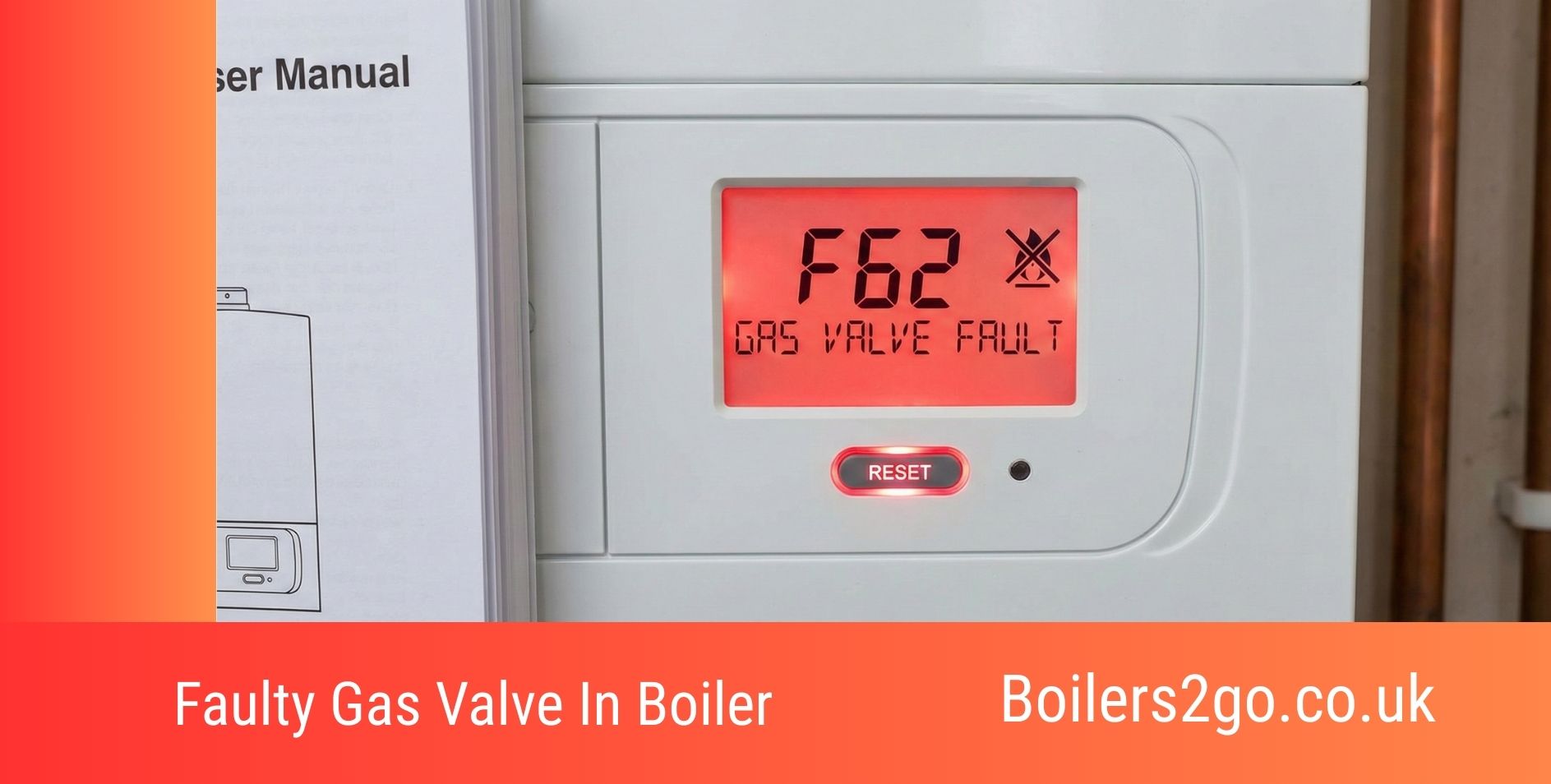

Dealing with a faulty gas valve in your boiler can be a frustrating experience, especially during the colder months when reliable home heating is essential. As a common issue in UK households, a faulty gas valve often leads to no hot water or central heating, prompting homeowners and landlords to seek quick, practical solutions.

In this guide, I’ll explore what a faulty gas valve means, its potential causes, and step-by-step fixes to help you restore your boiler’s functionality safely and efficiently.

What Causes a Faulty Gas Valve In a Boiler?

A faulty gas valve can be caused by several factors, ranging from everyday wear to installation errors, each impacting the valve’s ability to control gas flow effectively. Understanding these causes is crucial for diagnosing the issue accurately and avoiding unnecessary repair costs.

Below, I’ll detail the most common culprits, incorporating related terms like boiler gas supply problems, defective solenoid valves, and heating system malfunctions to provide a fuller picture.

Wear and Tear from Prolonged Use

Wear and tear from prolonged use is one of the primary causes of a faulty gas valve, as the constant opening and closing over years degrades internal components like seals and diaphragms.

In UK homes, where boilers often run extensively during winter, this natural degradation can lead to leaks or sticking valves, synonymous with terms like ageing boiler parts or deteriorated gas regulators.

How to Fix Wear and Tear on a Gas Valve

- To fix wear and tear on a gas valve, start by isolating the boiler’s power and gas supply to ensure safety, then inspect visible parts for signs of corrosion or damage.

- If you’re comfortable with basic DIY, clean any accessible debris using a soft brush, but for internal wear, replacement is often necessary—source a compatible part from manufacturers like Honeywell or SIT, and follow your boiler’s manual for installation.

- However, due to gas safety regulations in the UK, it’s advisable to consult a Gas Safe registered engineer for the actual fitting to comply with Building Regulations and avoid voiding warranties.

Dirt and Debris Buildup

Dirt and debris buildup is another frequent cause of a faulty gas valve, where particles from the gas supply or environment clog the valve’s orifices, restricting gas flow and leading to incomplete combustion.

This issue, often linked to poor maintenance or contaminated gas lines, can manifest as sputtering flames or error codes related to gas pressure faults in systems from brands like Ideal or Baxi.

How to Fix Dirt and Debris Buildup in a Gas Valve

- To fix dirt and debris buildup in a gas valve, begin by turning off the boiler and gas isolation valve, then carefully disassemble the valve if your model allows (refer to the user manual for diagrams).

- Use compressed air or a specialised valve cleaner to remove blockages, ensuring no residue remains before reassembly.

- For stubborn buildup, a professional flush of the gas lines might be required; always test for leaks post-cleaning using a gas detector, and remember that UK law mandates Gas Safe certification for any gas-related work to prevent hazards like carbon monoxide poisoning.

Electrical Faults or Wiring Issues

Electrical faults or wiring issues can cause a faulty gas valve by disrupting the signals from the boiler’s PCB (printed circuit board) to the valve’s solenoid, preventing it from opening or closing properly.

Common in homes with fluctuating power supplies or rodent damage to cables, this problem ties into broader boiler electrical problems and can trigger safety lockouts.

How to Fix Electrical Faults or Wiring Issues in a Gas Valve

- To fix electrical faults or wiring issues in a gas valve, first, safely disconnect the electricity at the fuse box and use a multimeter to check for continuity in the wiring harness connected to the valve.

- Replace any frayed wires with insulated equivalents matching the original specifications, and reset the boiler to clear any error codes.

- If the solenoid itself is faulty—indicated by no clicking sound on activation—procure a replacement from suppliers like Parts Center UK, but enlist a qualified electrician or Gas Safe engineer for verification, as improper handling risks electrical shocks or gas leaks.

Incorrect Gas Pressure

Incorrect gas pressure is a key cause of a faulty gas valve, occurring when the incoming gas supply is too high or low, straining the valve and leading to erratic operation or shutdowns. This can stem from supplier issues, faulty regulators, or problems in the meter, often associated with gas inlet pressure anomalies in UK domestic heating setups.

How to Fix Incorrect Gas Pressure Affecting a Gas Valve

- To fix incorrect gas pressure affecting a gas valve, measure the pressure at the boiler’s inlet using a manometer (available from plumbing merchants) and compare it to the manufacturer’s recommended range, typically 18-25 mbar for natural gas.

- If low, contact your gas supplier like British Gas to check for network issues; for high pressure, adjust or replace the external regulator.

- Avoid tampering with the valve itself without expertise, and always involve a Gas Safe professional to recalibrate and certify the system, ensuring compliance with Gas Safety (Installation and Use) Regulations 1998.

Manufacturing Defects or Poor Installation

Manufacturing defects or poor installation can cause a faulty gas valve right from the start, where substandard components or improper fitting lead to premature failure, such as misaligned connections causing vibrations or leaks. This is less common but relevant for recently installed boilers, relating to warranty-covered boiler defects and installation errors.

How to Fix Manufacturing Defects or Poor Installation in a Gas Valve

- To fix manufacturing defects or poor installation in a gas valve, review your boiler’s warranty documentation—most UK manufacturers like Viessmann offer 5-10 years coverage—and contact them for a free inspection if within terms.

- For installation issues, have the original fitter return to realign or reseal connections. In cases of defects, a full valve replacement under warranty is typical; document all communications and insist on Gas Safe accredited work to maintain safety standards and insurance validity.

How Can You Prevent a Faulty Gas Valve in the Future?

Preventing a faulty gas valve in the future involves regular maintenance and proactive checks to extend your boiler’s lifespan and avoid costly repairs. Schedule an annual service by a Gas Safe engineer, which includes cleaning the valve and checking gas pressure.

Additionally, install a magnetic filter to trap debris in the system, monitor for unusual boiler noises, and ensure your home’s gas supply is stable by reporting any meter irregularities promptly. For landlords, incorporate these into tenancy agreements to maintain compliance, while homeowners can benefit from boiler cover plans for added peace of mind.

When You Absolutely MUST Call a Gas Safe Engineer

There are situations when you absolutely must call a Gas Safe engineer to handle a faulty gas valve, as DIY attempts can lead to dangerous outcomes like gas explosions or carbon monoxide exposure.

If you smell gas, notice yellow flames instead of blue, or experience persistent error codes despite basic resets, contact a professional immediately—do not attempt fixes yourself. In the UK, only Gas Safe registered engineers are legally allowed to work on gas appliances, so verify their ID card via the Gas Safe Register website. For emergencies, dial the National Gas Emergency Service on 0800 111 999 without delay.

FAQs

Can a Faulty Gas Valve Affect My Home’s Energy Bills?

A faulty gas valve can indeed increase your home’s energy bills by causing inefficient gas usage, where the boiler cycles more frequently or burns excess fuel to compensate for poor regulation. Monitoring your meter readings and comparing them to previous months can help spot this early.

Is a Faulty Gas Valve Covered Under Home Insurance?

Whether a faulty gas valve is covered under home insurance depends on your policy; many standard buildings insurance plans exclude wear and tear, but optional boiler breakdown cover often includes valve repairs. Always check your policy documents or contact your insurer for specifics.

How Does Weather Impact a Faulty Gas Valve?

Extreme weather, like freezing temperatures in the UK, can exacerbate a faulty gas valve by causing condensate pipes to freeze or pressure fluctuations, leading to more frequent malfunctions. Insulating exposed pipes can mitigate this risk during winter.

What Role Does Water Quality Play in Gas Valve Faults?

Poor water quality, such as hard water in areas like London, can indirectly contribute to gas valve faults by scaling up the heat exchanger, which strains the entire system including the valve. Installing a water softener may help in high-limescale regions.

Are There Eco-Friendly Alternatives to Traditional Gas Valves?

Eco-friendly alternatives to traditional gas valves include those in modern condensing boilers or hybrid systems integrating renewables, which use advanced modulation for better efficiency. Exploring grants like the Boiler Upgrade Scheme could make upgrades more affordable for greener heating.

Stay warm, The Boilers2Go Team

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.