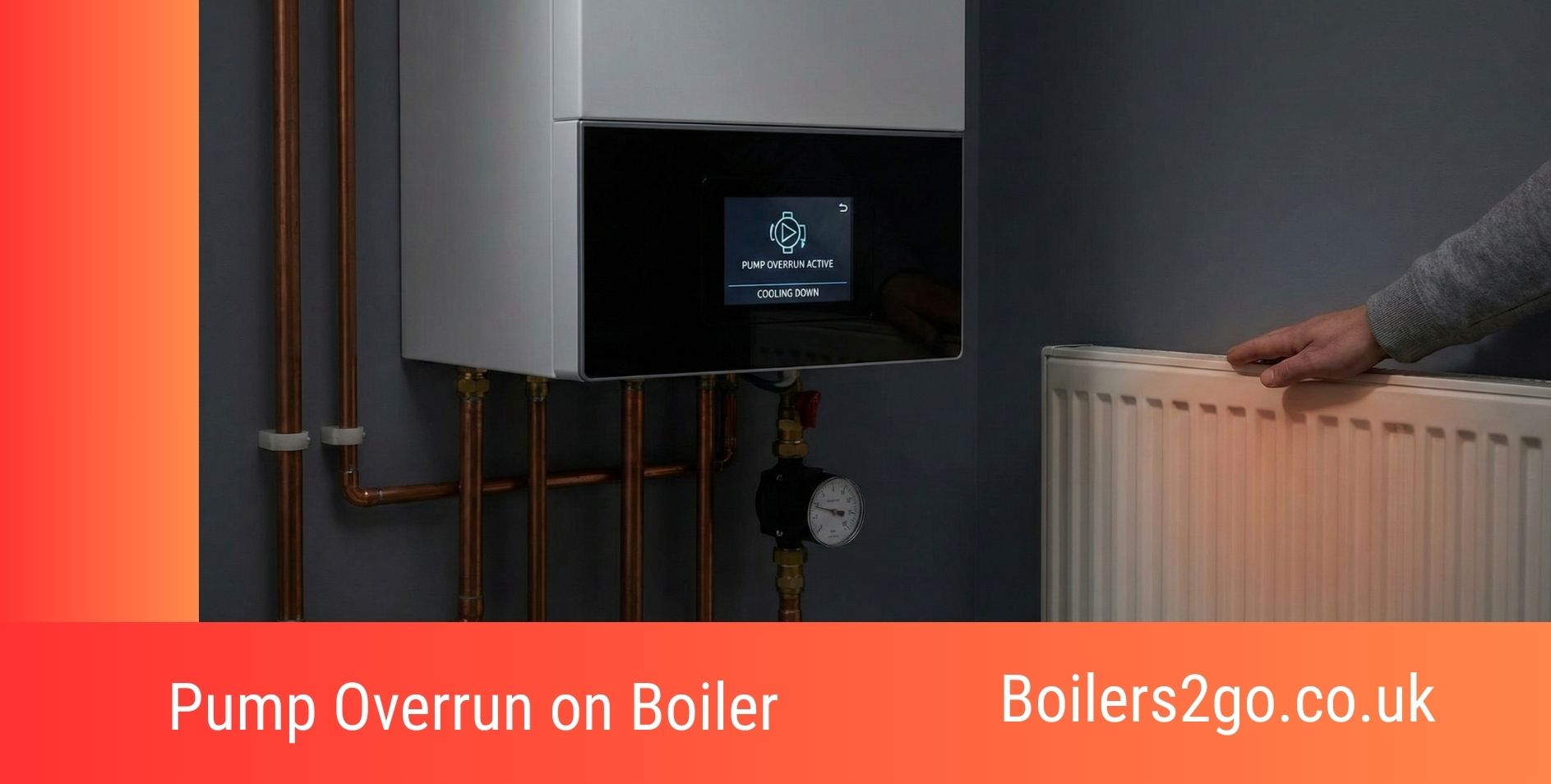

If you’ve noticed your boiler displaying an error code, making strange noises after shutting down, or the radiators staying warm long after the heating has turned off, you might be dealing with a pump overrun on boiler issue.

Pump overrun is a normal and essential safety feature in most modern UK boilers, but when something goes wrong with it, the boiler can lock out, flash a fault code, or behave oddly.

In this guide, I’ll explain exactly what pump overrun is, why it sometimes causes problems, the most common causes in UK homes, and clear step-by-step fixes you can try yourself — plus when it’s time to call a professional Gas Safe engineer.

What is Pump Overrun on a Boiler?

Pump overrun on a boiler is a built-in safety function that keeps the central heating pump running for a short period (usually 1–10 minutes) after the burner has turned off.

This continues to circulate water through the heat exchanger to remove residual heat and prevent the boiler from overheating, boiling, or “kettling”.

Almost all condensing combi and system boilers sold in the UK since the early 2000s have this feature — it’s a legal requirement under Building Regulations to protect the heat exchanger and improve efficiency.

Why Does Pump Overrun Sometimes Cause Fault Codes?

When the pump overrun function fails to work correctly, many boilers (especially Worcester Bosch, Vaillant, Ideal, Baxi and Glow-worm) will detect the problem and display a specific fault code or lockout. Common fault codes linked to pump overrun issues include:

- Worcester Bosch: F0, E9, or “Pump Overrun Fault”

- Vaillant ecoTEC: F62, F63 or S.53

- Ideal Logic / Max: F4 or L4

- Baxi / Potterton: E133, E168 or “Pump Fault”

- Glow-worm: F22 or pump-related errors

If your boiler shows one of these, it usually means the pump didn’t run (or didn’t run long enough) after the flame went out.

What Causes Pump Overrun Problems on a Boiler?

Here are the most common reasons UK homeowners and landlords see pump overrun faults:

1. Faulty or Seized Central Heating Pump

The central heating pump itself is the number one culprit.

How to fix a faulty or seized pump

- First, try a simple reset of the boiler.

- Locate the pump (usually underneath the boiler or in the airing cupboard on system boilers).

- You may be able to gently turn the pump spindle with a flat-head screwdriver through the centre cap to free it (only do this when the boiler is off and cool).

- If the pump is humming but not turning, or completely silent, it will need replacing. Average cost £180–£320 fitted by a Gas Safe engineer.

2. Blocked or Stuck Pump Valve / Motorised Valve

On system and regular boilers, motorised valves (2-port or 3-port) can stick in the wrong position and stop the pump running on overrun.

How to fix a stuck motorised valve

- Find the valve (often near the hot water cylinder or in the airing cupboard).

- The head can usually be removed without draining the system — switch it to “Manual” for a few minutes, then back to “Auto”.

- If the valve is stiff or the motor has failed, replacement costs £120–£250.

3. Printed Circuit Board (PCB) Fault

The main PCB controls the pump overrun timer and checks if the pump is running. A failed component on the board is very common after 8–12 years.

How to fix a PCB fault

- This is not a DIY job. A Gas Safe engineer will need to test the board with a multimeter and replace it if necessary. PCB replacement typically costs £250–£450 including labour.

4. Wiring or Relay Issue Between PCB and Pump

Loose, corroded or burnt wiring to the pump can stop the overrun signal reaching the pump.

How to fix wiring or relay problems

- Again, this requires a qualified engineer to safely check voltages and connections. Minor wiring fixes are usually under £150; a new wiring harness can be more.

5. Airlock or Sludge in the System

Thick black sludge (magnetite) or an airlock can make the pump struggle to turn, triggering the overrun protection.

How to fix sludge or airlock issues

- Bleed all radiators and check the pressure is 1–1.5 bar.

- Consider a full powerflush (£350–£600) or add a magnetic system filter (e.g., MagnaClean) to prevent future buildup.

6. Low System Pressure or Faulty Pressure Sensor

Many boilers check system pressure before allowing pump overrun. If pressure is below 0.5 bar or the sensor is faulty, overrun is blocked.

How to fix low pressure

- Top up via the filling loop until the gauge reads 1–1.5 bar when cold.

- If pressure keeps dropping, you have a leak somewhere — call an engineer.

How to Prevent Pump Overrun Faults in the Future

- Book an annual boiler service — a Gas Safe engineer will test the pump and valves every year.

- Fit a magnetic system filter (Adey MagnaClean, Fernox TF1, etc.) to catch sludge before it blocks the pump.

- Keep system pressure between 1 and 1.5 bar.

- Inhibitor levels should be checked every service — this stops corrosion and sludge forming.

- If your boiler is over 10 years old and pump faults are recurring, consider replacement — modern boilers have much more reliable pumps and PCBs.

When You Absolutely MUST Call a Gas Safe Engineer

You should call a registered Gas Safe engineer immediately if:

- You can smell gas or hear hissing.

- The boiler is leaking water.

- You’ve reset the boiler multiple times and the fault returns straight away.

- You’re not confident working on any part of the heating system.

- The fault code is accompanied by no heating AND no hot water (especially in winter).

DIY fixes are limited to very basic checks — anything involving electrics, gas, or sealed system components must be done by a qualified professional for safety and legality.

Stay warm, The Boilers2Go Team

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.