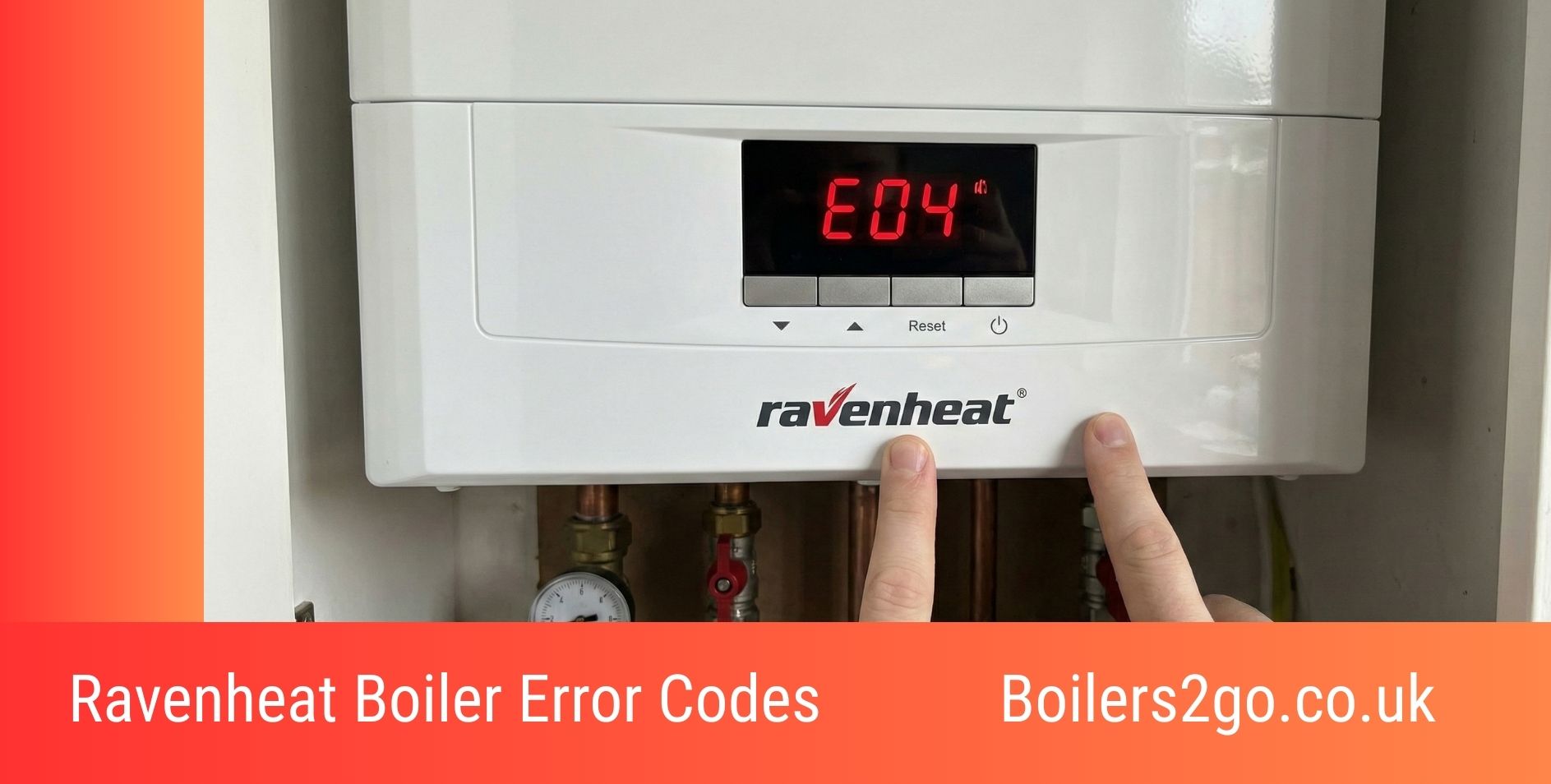

Encountering Ravenheat boiler error codes can be a frustrating interruption to your home heating system, leaving you without hot water or central heating on a chilly winter day. These diagnostic fault codes, displayed on the boiler’s control panel, are essential signals from your gas boiler that something isn’t right, helping you pinpoint issues before they escalate into costly repairs.

In this guide, I’ll break down the most common Ravenheat boiler fault codes, discuss their meanings, potential causes, and step-by-step fixes in plain English.

Whether you’re managing a rental property or your own family home, understanding these central heating error codes empowers you to act quickly—though remember, for any gas-related work, safety always comes first with a Gas Safe registered engineer.

What Are the Most Common Ravenheat Boiler Error Codes?

The most common Ravenheat boiler error codes typically revolve around ignition failures, circulation problems, pressure imbalances, and sensor malfunctions, affecting models across the range from older RSF units to modern condensing boilers.

These fault indicators light up on the digital display or LED panel, alerting you to disruptions in the combustion process, water flow, or electrical circuits within your home heating appliance.

For UK homeowners, recognising these early can prevent a full breakdown, especially during peak demand in autumn and winter when radiators and hot taps are in constant use.

Ravenheat Boiler Error Code 01 (Ignition Fault)

A Ravenheat boiler error code 01 signifies an ignition failure, where the boiler attempts to light the main burner but can’t establish or maintain a stable flame, resulting in no central heating or hot water supply.

This lockout code is one of the most reported in Ravenheat combi boilers, often triggered by the printed circuit board (PCB) detecting no flame signal after several tries.

In practical terms, it means your thermostat calls for heat, but the gas valve doesn’t open properly, leaving your home chilly and taps running cold— a nightmare for landlords facing tenant complaints.

What Causes Ravenheat Boiler Error Code 01?

- Ignition faults in Ravenheat boilers stem from several interconnected issues in the burner assembly and gas supply chain.

- Common culprits include a blocked or frozen condensate trap, which halts the drainage of acidic flue gases; a faulty flame detection electrode (also called an ionisation probe) that fails to sense the spark; or a dirty main burner clogged with debris from inefficient combustion.

- Electrical glitches, such as loose wiring to the spark generator or a failing PCB, can also interrupt the sequence, while low gas pressure from a faulty meter regulator exacerbates the problem. For properties in hard water areas like the South East, limescale on the electrodes adds another layer, reducing conductivity.

How to Fix a Blocked or Frozen Condensate Trap Causing Error Code 01

- If a blocked or frozen condensate trap is causing your Ravenheat boiler error code 01, start by locating the external plastic pipe at the base of the boiler, often routed to a drain.

- For freezing (common in uninsulated outdoor pipes during UK frosts), gently pour warm—not boiling—water over the pipe to thaw it, using a towel to catch drips and avoid scalding.

- Once thawed, check for blockages by shining a torch inside; clear minor debris with a flexible drain rod or wire hanger, then flush with warm water.

- Reset the boiler by pressing the reset button for 5 seconds. If it refires, monitor for recurrence—insulate the pipe with foam lagging to prevent future icing. This DIY fix suits confident homeowners but test hot water flow immediately.

How to Fix a Faulty Flame Detection Electrode for Error Code 01

- To address a faulty flame detection electrode behind Ravenheat boiler error code 01, first isolate the power supply at the fused spur to ensure safety.

- Remove the boiler’s front panel (consult your user manual for model-specific clips), then locate the probe near the burner—a small metal rod about 1cm long.

- Disconnect its wiring harness carefully, unscrew the electrode, and inspect for carbon build-up or bending; clean with fine emery paper if soiled, avoiding damage to the tip.

- Reinstall, reconnect, and power up for a reset. If the code persists, the electrode likely needs replacing— a £20-£30 part—but this requires Gas Safe expertise to avoid gas leaks. Landlords should schedule annual servicing to catch probe wear early.

How to Fix a Dirty Main Burner Injector Causing Error Code 01

A dirty main burner injector triggering Ravenheat boiler error code 01 demands careful cleaning to restore gas flow.

- Switch off gas and electricity, ventilate the room, and remove the burner assembly per your manual (typically four screws on the front). The injector is a brass nozzle at the burner’s base; use a soft brush or compressed air to dislodge fluff and soot, never poking with metal tools to avoid enlargement.

- Wipe with a lint-free cloth dampened in soapy water, rinse, and dry thoroughly before reassembling.

- Test ignition post-reset—if unstable, low gas pressure might be the root, necessitating a meter check by your supplier. This fix can extend burner life but always verify no gas odours before full operation.

Ravenheat Boiler Error Code E02

The Ravenheat boiler error code E02 indicates a pump circulation fault, where the internal pump fails to move water adequately through the primary heat exchanger and radiators, leading to inadequate heating distribution or boiler overheat protection kicking in.

This error code on the display halts operation to prevent damage, common in older Ravenheat system boilers like the WH90 where pump bearings seize from sludge accumulation in the closed-loop heating circuit.

What Causes a Pump Circulation Fault (E02) in Ravenheat Boilers?

- Pump issues causing Ravenheat boiler error code E02 often arise from airlocks trapped in the impeller, restricting rotation; mechanical seizure due to worn bearings or sludge from untreated central heating water; or electrical failures like a tripped capacitor in the pump motor.

- In rented properties, infrequent bleeding of radiators can introduce air, while hard water regions see faster scaling on the pump head.

How to Fix an Airlock in the Pump for Error Code E02

- To resolve an airlock causing Ravenheat boiler error code E02, first turn off the boiler and isolate power.

- Attach a hose to the pump’s manual bleed valve (a small screw on the pump body) and route it to a drain, then slowly open the valve while the system is cold to release trapped air bubbles—expect gurgling sounds as water flows.

- Top up pressure via the filling loop to 1-1.5 bar once bled, using a digital gauge for accuracy.

- Reset the boiler and run the pump override (hold the heating button for 5 seconds on most models) to circulate. This quick homeowner task restores flow but repeat if radiators remain cold upstairs.

How to Fix Mechanical Seizure of the Pump for Error Code E02

- Mechanical seizure behind Ravenheat boiler error code E02 requires accessing the pump shaft. With power off, remove the front panel and locate the pump (cylindrical component near the centre).

- Insert a flat screwdriver into the slotted shaft end and rotate clockwise gently—if stiff, apply penetrating oil sparingly and work it free over 10-15 minutes.

- Clean visible sludge with a cloth, avoiding disassembly unless experienced. Reassemble, reset, and test circulation by feeling for vibrations.

- If seized beyond this, pump replacement (around £150-£200 fitted) is needed, ideal during routine servicing for landlords.

How to Fix an Electrical Failure in the Pump Motor for Error Code E02

- For an electrical failure triggering Ravenheat boiler error code E02, check the pump’s wiring for loose connections—unplug, inspect terminals for corrosion, and reseat firmly.

- Test the capacitor (a small cylinder on the pump) with a multimeter set to capacitance; it should read near its rated microfarads (e.g., 2-4µF)—replace if low (£5-£10 part).

- Restore power and reset; if the motor hums but doesn’t spin, the windings may be burnt, requiring full pump swap by a Gas Safe pro. This fix highlights the need for annual electrical checks in high-use rental boilers.

Ravenheat Boiler Error Code 08E

Ravenheat boiler error code 08E points to low water pressure in the heating system, where the gauge drops below 0.5 bar, preventing safe operation to avoid dry-firing the heat exchanger.

This pressure fault code is prevalent in sealed systems, causing intermittent lockouts and poor radiator performance, especially after bleeding air from the central heating loop.

What Causes Low Water Pressure (08E) in Ravenheat Boilers?

Low pressure leading to Ravenheat boiler error code 08E can result from gradual leaks in radiator valves or flexible hoses, a faulty pressure relief valve (PRV) dripping externally, or a depleted expansion vessel that no longer absorbs pressure fluctuations. Droplet evaporation from minor seepages over time is subtle but cumulative in unmonitored landlord properties.

How to Fix Leaks in Radiator Valves for Error Code 08E

- To fix leaks in radiator valves causing Ravenheat boiler error code 08E, isolate the affected radiator by closing its lockshield and thermostatic valves, then drain via the bleed key into a bucket.

- Unscrew the valve nut, clean the olive and threads with a wire brush, and apply PTFE tape before reassembling tightly.

- Refill the system via the filling loop, monitoring the boiler gauge to 1.2 bar, and bleed again to expel air. For persistent drips, replace the valve (£15-£25) with a compression type—straightforward for DIY-savvy homeowners but check for underfloor corrosion.

How to Fix a Faulty Pressure Relief Valve for Error Code 08E

A faulty PRV behind Ravenheat boiler error code 08E needs replacement, as it can’t be serviced. Spot water near the safety valve on the boiler’s return pipe.

- Turn off power and water, relieve pressure by opening drain cocks, then unscrew the PRV (brass fitting, 3 bar rated). Fit a new one with a fibre washer, hand-tighten plus quarter-turn, and repressurise slowly.

- Test by running hot taps—no discharge means success. This £40-£60 job suits those with basic plumbing tools, but landlords should log it for compliance records.

How to Fix a Depleted Expansion Vessel for Error Code 08E

Depleted expansion vessel issues causing Ravenheat boiler error code 08E involve recharging. Tap the vessel (steel sphere on the system)—if it sounds solid, it’s waterlogged.

- Use a car tyre pump on the Schrader valve to inflate to 0.75 bar (matching cold system pressure), then check for air cushion by pressing the valve (hiss indicates success).

- Top up boiler pressure and reset. If no improvement, replace the vessel (£80-£120), a task for engineers to ensure vessel integrity in high-pressure setups.

Ravenheat Boiler Error Code F77

Ravenheat boiler error code F77 denotes a gas valve fault, where the solenoid-operated valve sticks open or closed, risking unsafe combustion or no ignition, often with a humming noise from the valve assembly. This fault code locks out the boiler immediately for safety, impacting hot water on demand in combi models.

Common Causes of Gas Valve Faults (F77) in Ravenheat Boilers

Gas valve problems resulting in Ravenheat boiler error code F77 include solenoid coil burnout from electrical surges, debris in the valve seat from poor gas quality, or diaphragm tears in the gas-air mixer unit. Over time, mineral deposits from mains gas variations harden components, more common in urban installations.

How to Fix Burnt-Out Solenoid Coils for Error Code F77

- Burnt-out solenoid coils causing Ravenheat boiler error code F77 require part replacement. Disconnect power and gas, remove the valve cover (two screws), and test coils with a multimeter—zero ohms means failure.

- Unsolder or unplug faulty coils (£30-£50 set) and fit new ones, ensuring polarity matches. Reassemble, purge air from gas lines, and relight via reset. Due to gas handling, this is strictly for Gas Safe engineers, emphasising pre-winter checks.

How to Fix Debris in the Gas Valve Seat for Error Code F77

- To clear debris in the gas valve seat behind Ravenheat boiler error code F77, isolate gas at the meter, ventilate, and disassemble the valve body.

- Use a soft brush to remove particles from the inlet filter and seat, flushing with clean gas oil if needed.

- Rebuild with new O-rings (£10 kit), test for leaks with soapy water on joints, and recommission. Professional intervention is mandatory to avoid carbon monoxide risks.

Ravenheat Boiler Error Code F85

Ravenheat boiler error code F85 signals a thermistor (NTC sensor) fault, where the temperature probe sends erratic readings to the PCB, causing erratic heating or shutdowns to prevent scalding. This sensor error affects flow or return thermistors, leading to lukewarm radiators or fluctuating hot water temperatures.

What Triggers Thermistor Faults (F85) in Ravenheat Boilers?

Thermistor faults for Ravenheat boiler error code F85 arise from wiring chafing against sharp edges, sensor overheating from dry runs, or calibration drift after years of limescale exposure. In multi-occupancy rentals, frequent hot water draws accelerate wear.

How to Fix Damaged Wiring on Thermistors for Error Code F85

Damaged wiring causing Ravenheat boiler error code F85 involves tracing harnesses from sensors to PCB.

- Power off, inspect for fraying (common near heat exchanger), and strip 1cm of insulation to splice with heat-shrink connectors and solder.

- Test continuity with a multimeter (near 10k ohms at 25°C). Secure with cable ties and reset—simple for electrically minded users, but verify no shorts.

How to Fix Overheating Damage to the Thermistor for Error Code F85

Overheating damage to the thermistor triggering Ravenheat boiler error code F85 means sensor replacement.

- Locate the NTC (bead-like resistor on pipes), unscrew, and fit a new one (£15-£25), coating threads with heat paste.

- Calibrate by running a heat cycle and checking display stability. Engineer recommended for precise fitting in confined boiler spaces.

How Can You Prevent Ravenheat Boiler Error Codes in the Future?

Preventing Ravenheat boiler error codes starts with proactive maintenance tailored to UK homes and rental properties, ensuring your central heating system runs smoothly year-round.

Schedule annual Gas Safe servicing to catch ignition or pump issues early, costing £80-£120 but saving on emergency call-outs.

Treat your heating water with inhibitor chemicals like Fernox F1 to combat sludge and limescale, especially in hard water areas—add via a radiator after flushing every two years. Insulate exposed pipes and the condensate trap to fend off freezing in sub-zero temps, and bleed radiators monthly during heating season to maintain pressure balance.

For landlords, install a magnetic system filter (£100-£200) to trap debris, and use smart thermostats for even loads, reducing thermistor stress. Regular pressure checks (1-1.5 bar cold) via the gauge prevent low-pressure faults, while educating tenants on resets avoids unnecessary lockouts. These habits extend boiler lifespan beyond the standard 10 years, minimising downtime and energy bills.

When You Absolutely MUST Call a Gas Safe Engineer

While simple resets or bleeding can tackle minor Ravenheat boiler error codes, certain scenarios demand immediate intervention from a Gas Safe registered engineer to safeguard your household from gas leaks, carbon monoxide poisoning, or explosion risks—non-negotiable under UK law for rented homes.

Call one urgently if error codes persist after basic troubleshooting, like repeated 01 ignitions hinting at gas supply faults, or F77 gas valve issues involving high-pressure components.

Any unusual smells (rotten eggs from gas), soot around the flue, or visible water leaks near electrical parts scream professional attention, as DIY tampering voids warranties and insurance.

For landlords, persistent circulation errors (E02) or sensor faults (F85) in older models may signal broader system corrosion, requiring certification for compliance.

Engineers carry the tools for safe gas purging and part swaps, often diagnosing via diagnostic software unavailable to homeowners. Prioritise this for vulnerable occupants like families or the elderly, and always verify the engineer’s Gas Safe ID before entry—peace of mind is priceless.

FAQs

How Often Should I Check My Ravenheat Boiler for Error Codes?

For optimal performance in a UK home heating setup, inspect your Ravenheat boiler’s display panel weekly during winter, noting any flashing lights or codes that could indicate emerging faults. This habit, combined with quarterly pressure and bleed checks, catches issues like low water levels before they trigger lockouts, extending efficiency without daily hassle.

What Does a Flashing Red Light Mean on a Ravenheat Boiler?

A flashing red light on your Ravenheat boiler often signals an electrical or sensor anomaly, distinct from numbered error codes, potentially linked to the PCB or wiring integrity. Unlike specific faults, it warrants a quick power cycle first, but persistent flashing points to deeper diagnostics best left to experts to restore safe operation.

Can Ravenheat Boiler Error Codes Affect My Energy Bills?

Yes, unresolved Ravenheat boiler error codes, such as circulation faults, force inefficient short-cycling, spiking gas usage by up to 20% as the unit struggles to maintain temperature. Addressing them promptly through servicing keeps your central heating optimised, aligning with UK energy-saving goals and reducing winter bills for cost-conscious households.

Are Ravenheat Boilers Prone to More Error Codes Than Other Brands?

Ravenheat boilers, while affordable, may show slightly higher error code frequencies in hard-water regions due to their compact designs accumulating scale faster than premium rivals like Worcester Bosch. However, with diligent water treatment, their reliability matches mid-range models, making them a solid choice for budget upgrades in rental portfolios.

How Do I Know If My Ravenheat Boiler Warranty Covers Error Code Repairs?

Ravenheat warranties (2-5 years standard) cover manufacturing defects causing error codes but exclude neglect like untreated water leading to pump faults. Check your installation certificate for expiry, and retain service records—contact Ravenheat support with the serial number for claims, ensuring any fixes don’t void coverage on your home heating investment.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.