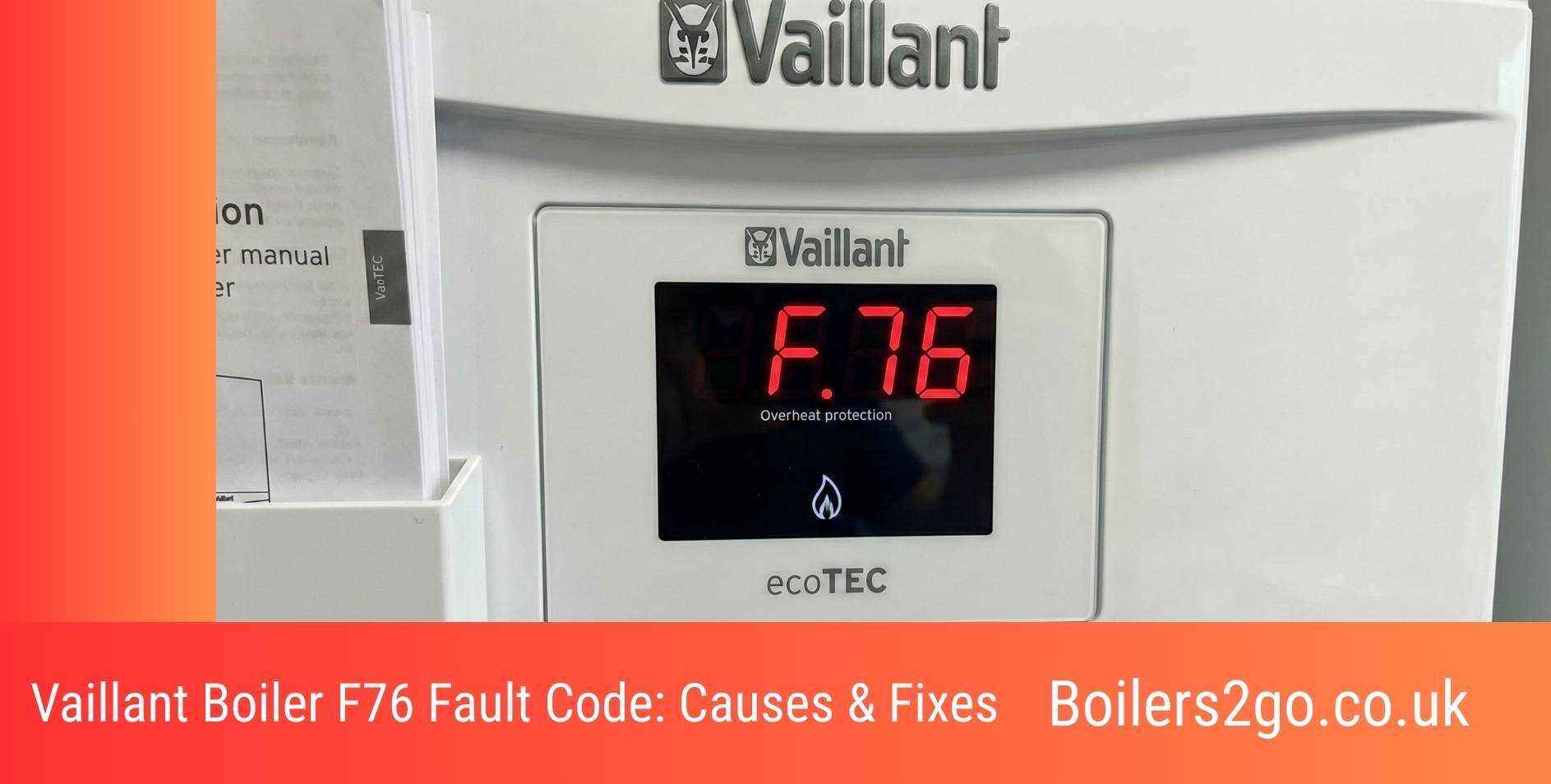

The Vaillant boiler F76 fault code is an emergency shutdown signal from your boiler’s printed circuit board (PCB), indicating that the overheating protection for the primary heat exchanger has been activated.

Think of the heat exchanger as the heart of your Vaillant combi boiler: it’s the component where cold mains water is heated by hot gases from the burner to provide your radiators and taps with warm water.

The F76 error specifically means the thermal fuse—a small, non-resettable safety device embedded at the top of this exchanger—has detected temperatures exceeding safe limits (typically around 95-105°C) and tripped to halt operations.

This fault code appears on digital displays in models like the ecoTEC 24, 28, 35, or 40, often accompanied by the boiler refusing to fire up, unusual humming or kettling noises from the unit, or intermittent hot water failures.

Unlike minor glitches such as low pressure (F22) or ignition issues (F28), the F76 is a red flag for potential heat exchanger failure, a common vulnerability in high-efficiency condensing boilers exposed to hard water regions across the UK.

For landlords managing rental properties, this could mean compliance risks under the Homes (Fitness for Human Habitation) Act 2018, as unreliable heating affects tenant welfare. Homeowners, meanwhile, face immediate discomfort and potentially higher energy bills if the system strains before fully locking out.

In essence, the Vaillant F76 error code protects your home from risks like scalding leaks or carbon monoxide exposure by prioritising safety over function. But ignoring it could escalate to costly repairs, so let’s explore the root causes next.

What Causes the Vaillant Boiler F76 Fault Code?

The Vaillant boiler F76 fault code typically stems from conditions that cause the primary heat exchanger to overheat, triggering the thermal fuse. This isn’t a random glitch; it’s a response to imbalances in water flow, sensor accuracy, or system blockages that prevent efficient heat dissipation. To address the F76 error, it’s crucial to inspect the heat exchanger and ensure there are no blockages in the system. Regular maintenance can help prevent such issues, but if the problem persists, you may want to explore alternative problems indicated by related codes, such as the vaillant boiler f26 error solutions. Implementing these troubleshooting measures can help restore optimal functionality to your heating system.

In UK homes, where limescale from hard water areas like the South East exacerbates these issues, the F76 fault often emerges after 5-10 years of use, especially if annual servicing has lapsed.

Common triggers include low water circulation, which starves the exchanger of coolant, or faulty components misreading temperatures. For semantic context, this fault relates to broader boiler troubleshooting entities like “condensing boiler efficiency,” “thermal cut-out mechanisms,” and “central heating system diagnostics.” Synonyms such as “Vaillant overheating error,” “F.76 lockout,” or “ecoTEC heat exchanger trip” highlight how searches for this fault overlap with queries on “boiler safety shut down” or “combi boiler fault finding.”

Below, we’ll detail the primary causes, each with tailored fixes. Remember, these are for informational purposes; hands-on work requires Gas Safe expertise to avoid voiding warranties or breaching UK gas regulations.

Cause 1: Tripped Thermal Fuse Due to Genuine Overheating

A tripped thermal fuse is the most direct trigger for the Vaillant boiler F76 fault code, where the exchanger’s temperature spikes beyond design limits because of underlying flow problems. This fuse is a one-time sacrificial link, melting at high heat to break the circuit and protect the PCB and flue from damage.

How to Fix a Tripped Thermal Fuse

First, isolate the boiler by switching off the power at the fused spur and turning the gas supply valve to “off”—this prevents accidental ignition.

A Gas Safe engineer will access the heat exchanger by removing the front casing, visually inspect for signs of melting or discolouration on the fuse (a small white or ceramic component), and test continuity with a multimeter (expect infinite resistance if blown).

Replacement involves sourcing a genuine Vaillant part (around £20-£50) and soldering or clipping it in place, but this only addresses the symptom. The engineer must then diagnose and resolve the root overheating—such as flushing the system—to prevent recurrence.

Total fix time: 1-2 hours; cost: £150-£300, excluding root cause repairs. For older boilers, if the exchanger shows warping, full replacement (£800+) or a new unit might be more economical.

Cause 2: Faulty Temperature Sensor or Wiring Connections

Faulty wiring or a malfunctioning temperature sensor (often the NTC thermistor) can falsely signal overheating to the PCB, prompting the Vaillant boiler F76 fault code even if actual temperatures are normal. Loose connectors corrode over time in humid airing cupboards, while sensors degrade from vibration or electrical surges.

How to Fix Faulty Temperature Sensor or Wiring

- A professional starts by resetting the boiler (hold the reset button for 5 seconds) to check if it’s intermittent—up to 90% of F76 cases in Vaillant ecoTEC models trace to dodgy plugs here.

- They’ll trace the wiring loom from the sensor (a probe on the exchanger outlet) to the PCB, using a multimeter to measure resistance (should be around 10kΩ at 25°C, dropping predictably with heat). Clean corroded pins with contact spray, re-seat connectors, or replace damaged cables (£50-£100 labour). If the sensor reads erratically, swap it out (part cost: £30-£60).

- This fix is quicker (under 1 hour) and cheaper (£100-£200 total) than exchanger work, but always test post-repair by running the boiler in hot water mode and monitoring via the diagnostic menu (press and hold i/0 + mode buttons).

Cause 3: Low Water Pressure or Blocked Pressure Sensor

Low system pressure (below 1 bar) or a clogged pressure sensor prevents water from circulating through the heat exchanger, causing dry firing and the Vaillant boiler F76 fault code. This is prevalent in properties with frequent radiator bleeds or undetected leaks, common in UK rentals with multiple occupants.

How to Fix Low Water Pressure or Blocked Pressure Sensor

- Check the pressure gauge first—if it’s low, top up via the filling loop (cold mains flexi-hose) to 1.5 bar when cold, then bleed radiators to expel air.

- For the sensor (a small diaphragm unit near the pump), the engineer drains the system slightly, removes the sensor, and cleans debris with a soft brush or compressed air—avoid harsh chemicals to prevent membrane tears.

- Test calibration by repressurising and running a cycle; if faulty, replace with a Vaillant-compatible unit (£40-£70). Pair this with a full system flush using a magnetic filter cleaner to remove sludge. Expect £120-£250 total, with prevention via quarterly pressure logs for landlords ensuring EPC compliance.

Cause 4: Airlocks or Blockages in the Heat Exchanger

Air pockets trapped in the pipes or limescale/debris blocking the exchanger fins restrict water flow, leading to hot spots and the Vaillant boiler F76 fault code. In hard water zones like London or the Midlands, scale buildup mimics a partial blockage, reducing efficiency by up to 20%.

How to Fix Airlocks or Blockages

- Bleed all radiators starting from the highest, using an automatic air vent key, while monitoring pressure drops. For stubborn airlocks, the engineer powers off, isolates, and uses a vacuum pump to extract air from the pump head and diverter valve.

- Blockages demand a chemical flush: add inhibitor like Fernox F3, run the system hot, then powerflush with a professional rig to dislodge scale (2-4 hours). In severe cases, dismantle the exchanger for ultrasonic cleaning or replace primary plates (£400-£700).

- Post-fix, add a limescale reducer if in a hard water area. Costs: £200-£500, with immediate relief from gurgling noises and uneven heating.

Cause 5: Faulty Pump or Diverter Valve Issues

A weak circulating pump or sticking diverter valve fails to push water adequately, starving the exchanger and activating the Vaillant boiler F76 fault code. These components wear from constant use in demand-heavy homes, like those with multiple bathrooms.

How to Fix Faulty Pump or Diverter Valve

- Listen for pump humming without flow—engineers test speed via the PCB menu (should ramp to 80-100% under load). Lubricate or replace the pump head (£100-£150 part) if seized.

- For the diverter (a motorised flap switching between heating/hot water), command it open/closed via diagnostics; clean or swap the actuator (£80-£120) if it chatters. Full pump replacement: £150-£300.

- Always check for error logs (F61/F62 often precede F76) and balance flow rates post-repair. This targeted fix restores modulation, improving A-rated efficiency.

How to Prevent the Vaillant Boiler F76 Fault Code in the Future

Preventing the Vaillant boiler F76 fault code boils down to proactive central heating maintenance, tailored for UK homeowners and landlords facing variable weather and water quality.

Schedule annual Gas Safe servicing (£80-£150) to inspect the thermal fuse, clean the exchanger, and test sensors—Vaillant recommends this for warranty validity up to 10 years. Install a magnetic system filter (£100-£200) to trap sludge, and use a water softener or scale inhibitor in hard areas to curb limescale, potentially extending exchanger life by 30%.

For rentals, log monthly pressure checks (1-2 bar) and educate tenants on bleeding radiators without over-depressurising. Monitor for early warnings like fluctuating hot water or unusual boiler sounds via smart thermostats like Hive.

These steps not only dodge F76 but boost energy savings under Ofgem’s efficiency standards, keeping your home heating reliable and bills in check.

When You Absolutely MUST Call a Gas Safe Engineer

While basic checks like pressure topping-up offer temporary insights, the Vaillant boiler F76 fault code demands a Gas Safe registered engineer without delay—DIY tinkering risks gas leaks, fires, or invalidating insurance.

Call immediately if the boiler won’t reset after three attempts, emits burning smells, or shows water pooling beneath (indicating exchanger cracks). For landlords, this is non-negotiable under the Gas Safety (Installation and Use) Regulations 1998, with fines up to £6,000 for non-compliance.

Expect a diagnostic visit (£60-£100 call-out) within 24 hours from certified pros via Vaillant’s network or platforms like Checkatrade. Prioritise this for safety, especially in family homes or multi-occupancy lets, to avoid escalation to full system failure.

FAQs

Can the Vaillant Boiler F76 Fault Code Be Covered Under Warranty?

Vaillant warranties (typically 5-10 years on ecoTEC models) cover F76 faults only if stemming from manufacturing defects, not wear from poor maintenance or hard water. Check your paperwork or Vaillant’s online portal with your serial number; extended plans like Vaillant Advance (£15/month) often include labour but exclude pre-existing issues. Always get a pre-claim inspection to confirm eligibility.

How Does Hard Water in the UK Affect the Vaillant F76 Fault?

Hard water, prevalent in 60% of UK regions, accelerates limescale in the heat exchanger, insulating fins and causing hot spots that trip the F76. This reduces flow by 15-20%, mimicking blockages. Mitigation via annual descaling or in-line softeners can defer faults, but in extreme cases like Essex, professional magnetic flushing every two years is advisable.

Is the F76 Fault More Common in Older Vaillant ecoTEC Models?

Yes, pre-2015 ecoTEC models (e.g., 624/637) show higher F76 incidence due to earlier sensor designs prone to corrosion. Newer plus variants incorporate improved NTC probes, dropping failure rates by 25%. If your boiler is 8+ years old, budget for upgrades during servicing to align with ErP energy directives.

What Noises Indicate an Impending Vaillant Boiler F76 Fault Code?

Kettling (boiling rumble) from the exchanger or persistent pump whining signal flow restrictions leading to F76. These differ from normal fan whir—monitor via the boiler’s acoustic profile. Early detection via apps like Vaillant’s myVAILLANT allows remote alerts, preventing lockout in off-peak hours.

Does Installing a New Pump Always Resolve Recurring F76 Errors?

Not always—a new pump addresses circulation but not if paired with a faulty diverter or sludge buildup. Diagnostics reveal 40% of recurrences stem from unaddressed system contamination. Opt for a full hydraulic test post-install to ensure balanced flow, especially in larger homes with underfloor heating.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.