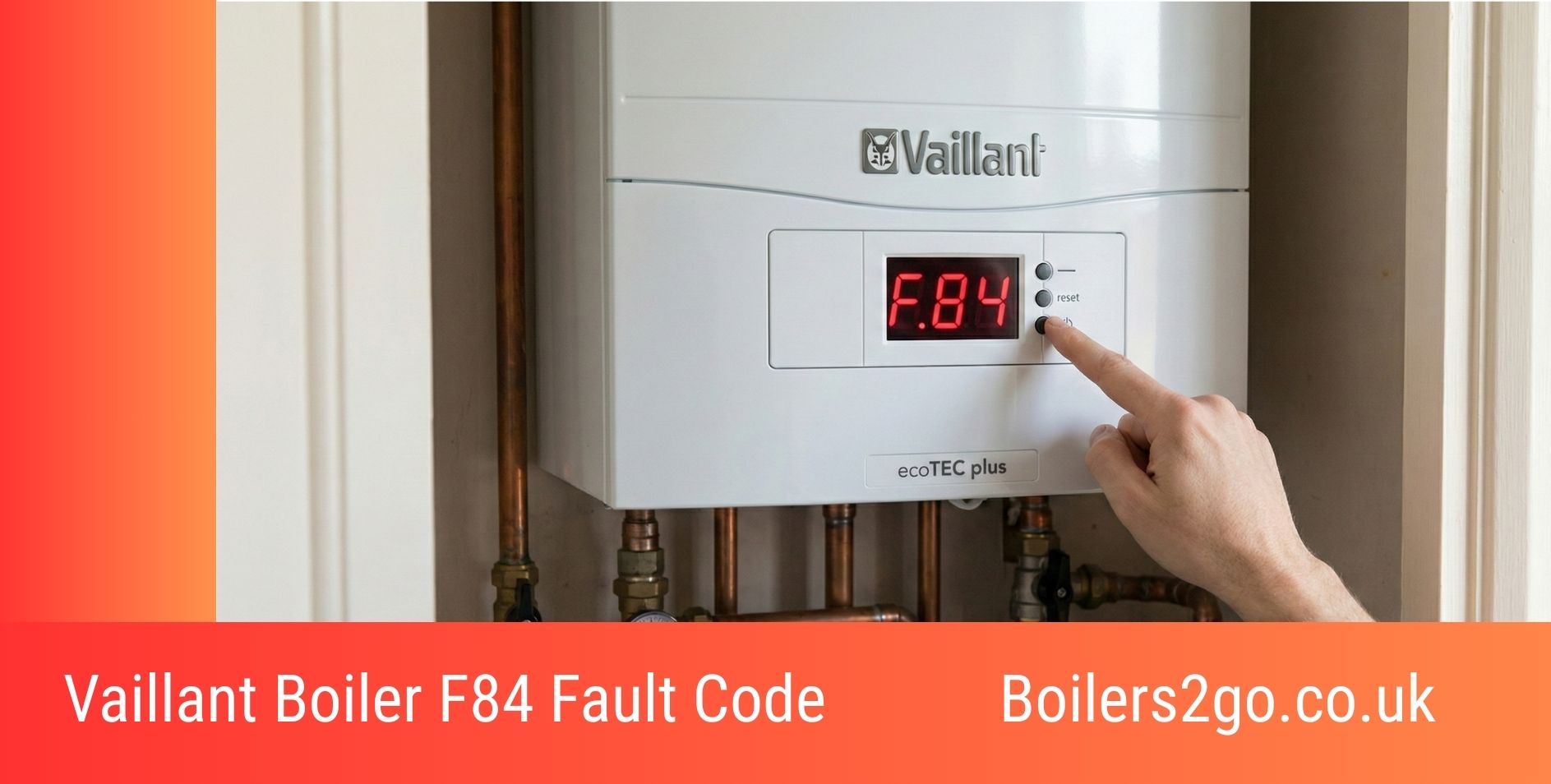

Encountering the Vaillant boiler F84 fault code on your ecoTEC or ecoFIT combi boiler’s display can halt your central heating and domestic hot water supply, leaving your home chilly during the colder months.

In this guide, I’ll explain what the F84 error code means. I’ll also discuss common causes, and outline safe troubleshooting steps to restore your heating system efficiently.

What Does the Vaillant Boiler F84 Fault Code Mean?

The Vaillant boiler F84 fault code means the control board has identified a permanent temperature difference between the flow and return NTC thermistors that exceeds safe operating parameters, typically more than 35°C under normal conditions.

In plain language, the NTC thermistors, small sensors that act like digital thermometers monitoring water temperature as it leaves (flow) and returns to the boiler are sending mismatched readings, causing the boiler to shut down to avoid overheating or inefficient combustion in your home’s heating circuit.

This fault is prevalent on Vaillant ecoTEC Plus, Pro, and Exclusive models installed in thousands of UK properties, from terraced houses in Manchester to rental flats in Edinburgh, where consistent radiator performance and on-demand hot water are vital.

Unlike low-pressure issues, F84 isn’t resolved by simple repressurisation, and it often requires professional intervention to ensure compliance with Gas Safe regulations.

What Causes the Vaillant Boiler F84 Fault Code?

The F84 error arises when the boiler’s temperature monitoring system fails to synchronise, often due to sensor inaccuracies or installation flaws that disrupt the feedback loop to the printed circuit board (PCB). This malfunction can lead to improper temperature readings, potentially causing the boiler to operate inefficiently or even shut down as a safety precaution. Similar issues can be observed in other models, such as the Vaillant boiler F24 fault code explanation, which highlights the importance of thorough maintenance and regular checks on sensor functionality. Addressing these issues promptly can prevent more serious problems and ensure optimal performance of the heating system.

Based on diagnostics from Gas Safe engineers nationwide, here are the key causes, each with context on how they develop in everyday UK heating setups like unserviced systems in hard-water areas or older properties with variable flow rates.

Cause 1: Faulty or Drifting NTC Thermistors

NTC thermistors naturally degrade over time, with their resistance values shifting due to age or exposure to heat cycles, leading to inaccurate temperature readings that trigger F84. In boilers over 5–7 years old, this is common in high-demand households where the sensors endure frequent on-off cycles, such as in families relying on combi boilers for multiple bathrooms.

How to Fix Faulty NTC Thermistors Causing F84

- Diagnostic Testing: A Gas Safe engineer uses a multimeter to measure resistance at ambient temperature (should be around 10k ohms at 25°C for both flow and return sensors); discrepancies confirm failure.

- Replacement Procedure: Isolate power and water, then swap the faulty thermistor(s) – a clip-in job taking 30–45 minutes with genuine Vaillant parts (£30–£50 each). Total cost: £150–£250 including calibration to sync with the PCB.

- Verification Step: Post-replacement, run a heat-up cycle and monitor differentials via the boiler’s service menu to ensure readings stay within 20–30°C, optimising energy efficiency.

Cause 2: Incorrectly Fitted or Calibrated Thermistors

During initial installation or recent servicing, thermistors may be loosely connected, reversed, or calibrated outside factory specs, causing persistent mismatches that the PCB interprets as a fault. This often occurs in rushed jobs on new-build sites or DIY-adjacent repairs in rental properties, where precise sensor placement on the flow/return pipes is overlooked.

How to Fix Incorrectly Fitted Thermistors Causing F84

- Visual and Connection Check: Engineer removes the boiler casing to inspect wiring harnesses for secure plugs and correct orientation (flow NTC on outgoing pipe, return on incoming); reseat as needed without tools.

- Recalibration: Access the diagnostic mode (hold mode and + buttons) to reset sensor offsets, then test with a temperature probe for accuracy. This fix is low-cost (£80–£120) if no parts are required.

- Full Reinstallation: If damaged, refit with thermal paste for better contact, followed by a full system balance to prevent flow imbalances exacerbating the issue.

Cause 3: Wiring or Connection Issues to the Thermistors

Corroded, frayed, or loose wiring between the NTC sensors and PCB interrupts signal transmission, mimicking a temperature fault and activating F84. In damp UK environments like basements or unventilated airing cupboards, condensation accelerates corrosion, especially in boilers near external walls prone to moisture ingress.

How to Fix Wiring Issues Causing F84

- Continuity Test: Using a multimeter, trace the harness from sensors to PCB for breaks (resistance under 1 ohm); clean corroded terminals with contact spray.

- Repair or Replacement: Solder minor frays or install a new wiring loom (£40–£70 part), ensuring IP-rated seals against humidity. Labour: £100–£200, with a full electrical safety check per BS 7671.

- Preventive Sealing: Apply dielectric grease to connections during service to repel moisture, reducing recurrence in high-humidity postcodes.

Cause 4: PCB Malfunction or Software Glitch

The PCB processes thermistor data; if it’s corrupted by power surges or firmware bugs, it falsely flags permanent differentials, locking out with F84. Common in areas with unstable grids, like rural Scotland, or after lightning strikes affecting older ecoTEC models without surge protection.

How to Fix PCB Malfunction Causing F84

- Power Cycle Reset: Switch off at the fused spur for 15 minutes to clear glitches – effective for 10–15% of cases without tools.

- Firmware Update and Diagnostics: Engineer connects a Vaillant OPUS tool to flash latest software and log error history; if hardware fault, replace PCB (£200–£350). Transfer settings from old board to minimise downtime.

- Surge Protection Add-On: Install a mains conditioner (£50–£100) post-repair to shield against voltage spikes, ensuring stable thermistor communication.

Cause 5: Underlying System Imbalances Mimicking Sensor Faults

Severe sludge buildup or airlocks create real temperature gradients (e.g., hot flow but cool return), which the PCB misattributes to thermistors, triggering F84. This is frequent in neglected systems in London rentals with hard water, where limescale restricts flow without obvious leaks.

How to Fix System Imbalances Causing F84

- Bleed and Balance: DIY bleed all radiators (lowest first) and adjust lockshield valves for even heat; repressurise to 1.2 bar if needed.

- Power Flush Service: Professional high-pressure clean circulates descaler through pipes (£300–£500), removing debris and adding inhibitor for corrosion protection.

- Filter Integration: Fit an in-line magnetic filter (£100–£150) to capture ferrous particles, maintaining balanced flow and accurate NTC readings long-term.

How to Reset a Vaillant Boiler After Resolving F84

Once the cause is addressed:

- Confirm system pressure at 1–1.5 bar and bleed any air.

- Press and hold the reset button (spanner icon) for 3–5 seconds until the display blinks and clears.

- Observe a full heating cycle (10–15 minutes) for stable operation; log any recurrence for the engineer. Resets alone won’t fix F84 – always tackle the root issue first to avoid PCB strain.

FAQs

How does boiler age influence F84 occurrences?

Vaillant boilers over 6 years show F84 up to 30% more frequently due to thermistor wear, per service logs – early annual checks can extend sensor life significantly.

Can external thermostats trigger false F84 readings?

Incompatible third-party controls like basic Honeywell models can cause erratic flow, amplifying differentials; opt for Vaillant VRC-compatible stats for seamless integration.

What’s the link between F84 and energy efficiency drops?

Mismatched thermistors force inefficient cycling, hiking gas bills by 5–10%; resolving F84 restores ErP A-rated performance in ecoTEC units.

Do hard water areas see more F84 faults?

Yes, limescale in regions like Kent corrodes connections faster, contributing to 40% of F84 cases – water softeners mitigate this over time.

How does F84 differ from F85 on Vaillant models?

F84 flags flow-return discrepancies, while F85 indicates isolated return NTC issues; both need sensor checks but F85 often ties to return pipe sludge.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.