Warmflow boiler error codes are electronic indicators shown on the LCD display or via illuminated lights that signal a specific malfunction in the boiler’s operation, such as flame failure or overheating in your domestic heating setup.

These codes serve as a safety mechanism in high-efficiency condensing oil boilers, locking out the unit to prevent hazards like incomplete combustion or system damage, common in off-grid UK homes reliant on kerosene tanks.

Designed for easy interpretation, they appear in red for critical errors (requiring immediate action) or blue for warnings, helping maintain energy efficiency and reduce downtime in rental properties or family homes across Northern Ireland and Great Britain.

In this guide, I’ll explain most frequent Warmflow fault codes, their meanings, root causes, and step-by-step fixes, ensuring you can troubleshoot safely while complying with Oil Firing Technical Association (OFTEC) standards.

Most Common Warmflow Boiler Fault Codes

What Does Warmflow Error Code E01 Mean?

Warmflow error code E01 means no flame has been detected during the boiler’s start-up sequence, indicating an ignition lockout where the burner fails to light properly.

What Causes Warmflow E01 No Flame Detected?

- Insufficient Oil Supply: The fuel tank runs low or the line filter clogs with sludge, starving the Riello or similar burner of kerosene – a frequent issue in rural UK setups where tanks settle during low-use summers.

- Faulty Ignition Electrode: The spark electrode becomes dirty or misaligned from soot buildup, preventing consistent arcing to ignite the oil mist, especially in unserviced boilers exposed to dusty airing cupboards.

- Photocell or Flame Sensor Failure: The sensor can’t confirm flame presence due to carbon deposits or wiring faults, common after short-cycling in hard-water areas where limescale affects combustion.

How to Fix Warmflow E01

- Oil Supply Check: Inspect the tank gauge (ensure above 20% full) and replace the inline filter (£15–£25 from suppliers like OFTEC-approved stockists); bleed air from the line by cracking the burner pipe union slightly – this resolves 40% of E01s DIY.

- Electrode Maintenance: With power and fuel isolated, clean the electrode tip with fine sandpaper and realign to 3–5mm gap per the manual; test spark by manually triggering ignition (engineer recommended for safety).

- Sensor Replacement: A qualified OFTEC engineer tests photocell resistance (10–20k ohms) and swaps it (£40–£60 part); full burner service (£150–£250) includes combustion analysis to verify safe CO levels under 0.004%.

What Does Warmflow Error Code E02 Mean?

Warmflow error code E02 means the safety thermostat has tripped due to overheating, typically at 95°C, shutting down the boiler to protect the heat exchanger.

What Causes Warmflow E02 Safety Thermostat Tripped?

- Poor Water Circulation: Sludge or airlocks restrict flow through pipes and radiators, creating hot spots – prevalent in older UK properties with cast-iron systems where rust flakes accumulate over years.

- Pump Seizure: The internal or external pump (often Grundfos) sticks from lack of lubrication or debris, failing to move water and causing rapid temperature rises in combi models during hot water demand.

- Thermostat Wiring Fault: Loose connections or corrosion interrupt the stat signal, falsely triggering the trip in damp environments like unventilated boiler houses.

How to Fix Warmflow E02

- Circulation Boost: Bleed all radiators starting from the lowest and top up system pressure to 1–1.5 bar via the filling loop – this purges air and often resets E02 without tools.

- Pump Inspection: Engineer frees the pump shaft by removing the central screw and rotating manually; if seized, replace the head (£120–£200 fitted), testing flow rate at 20–30 l/min.

- Wiring and Stat Reset: Trace and tighten connections with a multimeter for continuity; manually press the red reset button on the stat – full replacement (£50–£80) if faulty, followed by a system balance.

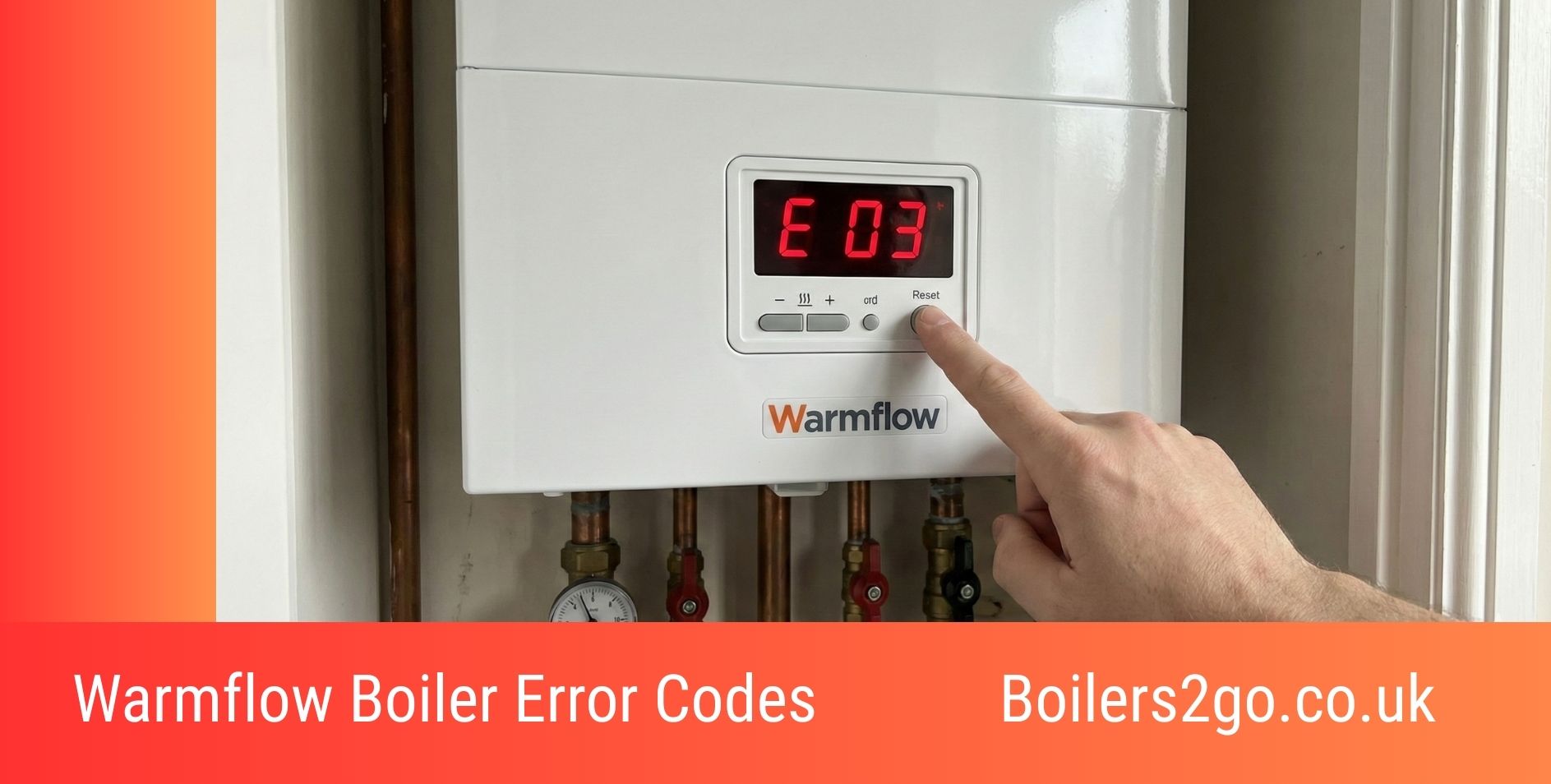

What Does Warmflow Error Code E03 Mean?

Warmflow error code E03 means the flue thermofuse has tripped, a one-time safety device activating from excessive exhaust temperatures to prevent flue gas leaks.

What Causes Warmflow E03 Flue Thermofuse Tripped?

- Flue Blockage: Debris like bird nests or soot buildup in the chimney restricts exhaust, raising backpressure and temperatures – common in external flues exposed to coastal winds or leaves in autumn.

- Incorrect Flue Installation: Poor gradient or undersized ducting (below 80/125mm spec) causes turbulence, overheating the fuse in high-output Enviroblue models.

- Burner Overfiring: Misadjusted air-fuel ratio floods the chamber with excess oil, spiking flue heat in uncalibrated burners after filter changes.

How to Fix Warmflow E03

- Flue Clearance: Visually inspect the terminal for obstructions and use a flue brush to clear soot; engineer performs a sweep (£100–£150) with CCTV if internal.

- Installation Review: Confirm flue pitch (3° min) and length (under 4m horizontal); reroute or extend as per OFTEC CI/66 guidelines (£200–£400 labour).

- Fuse and Burner Tune: Replace the thermofuse (£20–£40) and recalibrate burner pressure (7–10 bar oil) with a manometer – essential combustion test ensures efficiency over 90%.

What Does Warmflow Error Code E05 Mean?

Warmflow error code E05 means low system water pressure has been detected, usually below 0.5 bar, halting operation to avoid air ingress damage.

What Causes Warmflow E05 Low System Pressure?

- Leaks in Pipework: Drips from joints or radiator valves deplete pressure over time, accelerated in rented properties with high tenant turnover and poor maintenance.

- Expansion Vessel Failure: The vessel’s bladder ruptures, unable to absorb thermal expansion – typical after 5–7 years in unserviced systems.

- Filling Loop Fault: Stuck or leaky loop valves allow slow drainage, common in hard-water areas where scale jams the mechanism.

How to Fix Warmflow E05

- Repressurisation: Locate the braided hose or twin valves under the boiler and open slowly to raise the gauge to 1.2 bar cold; close firmly and monitor for drops.

- Vessel Recharge: Engineer presses the Schrader valve – water spray means failure; recharge to 0.75 bar air or replace (£80–£150), isolating the system first.

- Leak Detection: Use dye in the header tank and UV light to trace; seal with PTFE tape or new washers (£50–£100), followed by inhibitor addition for corrosion protection.

What Does Warmflow Error Code E16 Mean?

Warmflow error code E16 means a sensor fault, often the flow or return NTC thermistor failing to provide accurate temperature feedback.

What Causes Warmflow E16 Sensor Fault?

- Sensor Drift: Age or heat cycles alter resistance values, misreading temps in high-demand combis – frequent in families with multiple showers.

- Wiring Corrosion: Moisture in the control panel erodes connections, interrupting signals in basement installations.

- PCB Incompatibility: Faulty board misinterprets sensor data post-firmware glitch from power surges.

How to Fix Warmflow E16

- Resistance Test: Multimeter check at 25°C (10k ohms nominal); clean contacts if minor corrosion.

- Sensor Swap: Replace NTC (£30–£50) clipped to pipes, recalibrating via service mode for precise modulation.

- Board Diagnostics: Engineer flashes updates or replaces PCB (£200–£350), logging faults for warranty claims.

What Does Warmflow Error Code E22 Mean?

Warmflow error code E22 means a fan fault, where the induced draught fan fails to extract flue gases adequately.

What Causes Warmflow E22 Fan Fault?

- Motor Seizure: Bearings wear from dust ingress, slowing RPM below 3000 in loft-mounted units.

- Blocked Air Intake: Filters clog with pollen or insects, reducing airflow in external vents.

- Electrical Supply Issue: Loose wiring or voltage drop interrupts fan operation during startup.

How to Fix Warmflow E22

- Filter Clean: Vacuum intake grille and replace foam filter (£10–£20 annually).

- Motor Test: Engineer measures speed with tachometer; lubricate or replace fan (£150–£250), ensuring 80/125mm duct compatibility.

- Wiring Secure: Tighten terminals and test voltage (230V AC); add stabiliser if grid fluctuations persist.

FAQs

How does oil quality impact Warmflow error code risks?

Substandard kerosene with high sulphur content accelerates soot on sensors, raising E01 and E16 frequency by 25% – always source Class C2 fuel from vetted suppliers.

Can smart controls integrate without triggering Warmflow faults?

Viable with OpenTherm-compatible thermostats like Honeywell Evohome, which smooth modulation to cut overheat E02 risks; avoid basic on/off stats for condensing efficiency.

What’s the role of annual OFTEC servicing in preventing codes?

Routine burner tunes and flue sweeps slash E03 and E22 occurrences by 50%, per industry benchmarks, while validating 5–10 year warranties on Enviroblue models.

Do Warmflow combis show unique codes for hot water priority?

Yes, diverter-related variants of E05 may appear during dual demands, distinct from system boilers – prioritising hot water flow at 15 l/min avoids this in rentals.

How does location affect E22 fan faults in UK homes?

Coastal properties with salty air corrode fan motors 30% faster, per service data; sealed enclosures and annual greasing mitigate this for longevity.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.