Common Viessmann boiler problems usually means your Viessmann Vitodens, Vitodens 100-W, Vitodens 050-W, or Vitodens 200-W has stopped working properly – and you want it sorted fast without necessarily paying for an emergency call-out.

In this guide, I’ll explain the most frequent Viessmann fault codes, what they actually mean, the exact causes, and step-by-step fixes you can safely try yourself as a homeowner or landlord. I’ll also tell you exactly when a job is strictly for a Gas Safe registered engineer.

What Are the Most Common Viessmann Boiler Fault Codes?

The most common Viessmann boiler fault codes that UK homeowners and landlords see are F2, F4, F5, E1/F1, FD, F9, and 0A. These appear on the boiler display (or via the ViCare app on newer models) and point to specific issues with burner flame, pressure, sensors, or ignition. Understanding the implications of these fault codes is crucial for timely maintenance and ensuring efficient operation.

For instance, the viessmann f2 fault code explanation indicates a problem with the burner flame detection process, which can lead to the boiler shutting down to prevent unsafe conditions.

Addressing these codes promptly can help avoid more significant issues down the line and maintain the boiler’s performance. Additionally, the viessmann boiler f1 fault code signals a malfunction in the boiler’s sensor system, which could result in incorrect temperature readings and inefficient operation. Ignoring this issue may lead to increased energy costs and potential system failures.

Regularly monitoring these fault codes allows homeowners to take proactive measures, ensuring their heating systems operate smoothly year-round. Another common alert is the viessmann boiler f5 fault code, which indicates a problem with the system’s water flow or pressure.

Homeowners should investigate possible blockages or issues with the pump to avoid further complications. Regular servicing and checks can mitigate the risk of encountering these faults and ensure the boiler remains reliable throughout the colder months.

Watch Our Video on Common Viessmann Problems:

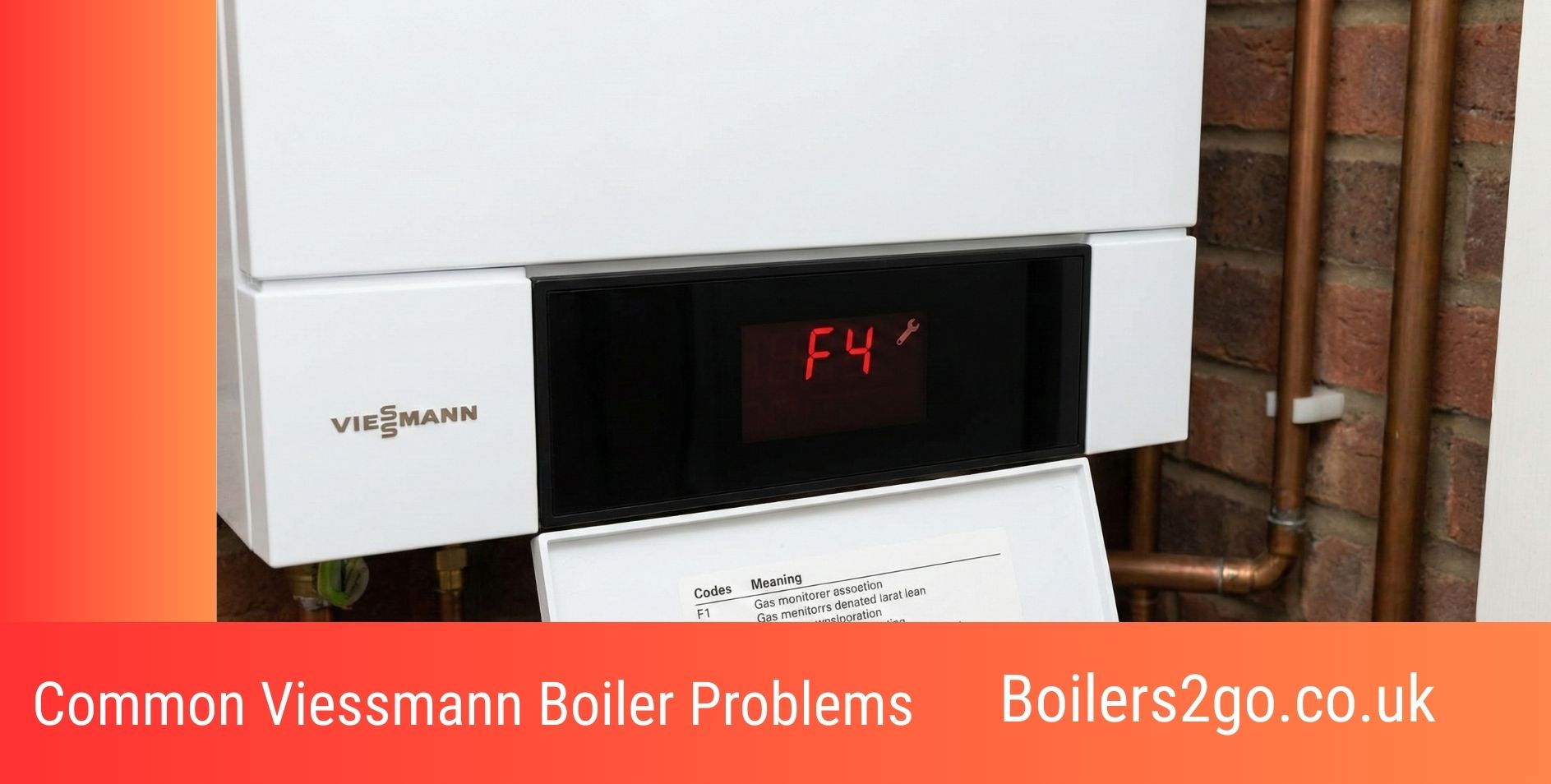

Fault Code F4 – No Flame Detected / Boiler Lockout

F4 means the boiler tried to light but no flame was detected (or the flame went out straight after ignition).

Common Causes of F4

- Frozen or blocked condensate pipe (extremely common in winter)

- Gas supply issue – closed gas valve or very low incoming gas pressure

- Faulty ignition electrode or lead

- Blocked or dirty burner

- Air in the gas line after new gas work

How to Fix F4 Yourself

- Check for a frozen condensate pipe – The white 22mm plastic pipe that exits outside is the usual culprit. Pour warm (not boiling) water over the frozen section or use a hot water bottle. Once thawed, reset the boiler.

- Check the gas supply – Make sure the gas meter emergency control valve (the lever by the meter) is fully open and in line with the pipe.

- Reset the boiler – Press and hold the reset button (usually marked with a flame and spanner symbol) for 3–5 seconds. Newer Viessmann models reset via the display menu.

- If it locks out again immediately, stop and call a Gas Safe engineer – it’s likely an ignition electrode, gas valve, or PCB issue.

Fault Code F2 – Overheat Lockout / High Limit Stat Tripped

F2 appears when the boiler detects the water temperature has become dangerously high and shuts down for safety.

Common Causes of F2

- Low system water pressure (below 0.8 bar)

- Pump failure or seized pump

- Blocked main heat exchanger

- Closed or partially closed radiator valves causing poor circulation

How to Fix F2 Yourself

- Check boiler pressure – Look at the pressure gauge (usually under the boiler). It should be between 1 and 1.5 bar when cold. If low, repressurise using the filling loop (two silver braided hoses with small taps/valves). Open both slowly until you reach 1.2 bar, then close tightly.

- Bleeding radiators – Trapped air can cause hot spots. Bleed every radiator starting downstairs and working up.

- Check the pump is running – You should hear a gentle hum and feel vibration on the pump body (usually a large brass component in the middle of the boiler).

- If pressure is correct and it still shows F2, do not keep resetting – call a Gas Safe engineer (possible pump or heat exchanger blockage).

Fault Code F5 – Flue Overheat or Air Pressure Switch Fault

F5 indicates the boiler has detected excessive flue temperature or the air pressure switch has not operated correctly.

Common Causes of F5

- Blocked or obstructed flue terminal outside (bird guards full of leaves, snow, wasp nests)

- Fan fault or restricted fan operation

- Flue not installed to manufacturer’s instructions (rare in newer installs)

How to Fix F5 Yourself

- Safely inspect the flue terminal outside – clear leaves, snow, or debris from the guard.

- Make sure nothing is within 300 mm of the terminal (plants, washing, etc.).

- Reset the boiler once cleared.

- If the fault returns immediately, it’s usually a fan or air pressure switch issue – Gas Safe job.

Fault Code FD – Water Pressure Too High (Vitodens 100/111/200)

FD shows when system pressure exceeds about 3 bar (often after someone has over-filled the system).

How to Fix FD Yourself

- Locate a radiator with a normal bleed valve (not the towel rail).

- Attach a bleed key and cloth/hosepipe to direct water into a bucket.

- Bleed until the pressure drops to 1.2–1.5 bar.

- Check the filling loop taps are fully closed and caps replaced.

Fault Code 0A or Flame Signal Lost (Some Models)

0A means the flame was established but then disappeared during operation.

Common Causes of 0A

- Very low or fluctuating gas pressure

- Dirty or misaligned flame detection electrode

- Strong wind blowing back down the flue (common on windy days with horizontal flues)

How to Fix 0A Yourself

- Reset the boiler twice – sometimes wind gusts cause temporary loss.

- If it keeps happening, call a Gas Safe engineer for gas pressure testing and electrode cleaning/replacement.

How Can You Prevent Viessmann Boiler Fault Codes in the Future?

Prevention beats cure every time:

- Annual Gas Safe service – This is a legal requirement for landlords and the single best way to avoid 90 % of faults.

- Fit a magnetic system filter (Magnaclean, Fernox TF1, etc.) to keep the system clean.

- Lag the condensate pipe with proper outdoor foam insulation or trace heating tape in cold areas.

- Keep boiler pressure checked monthly – mark 1.2 bar on the gauge with a marker pen so you can see at a glance.

- Use an inhibitor (Fernox F1 or Sentinel X100) and top up every 5 years.

- Install a weather compensation probe (if your model supports it) – reduces cycling and wear.

When You Absolutely MUST Call a Gas Safe Engineer

Never attempt these repairs yourself:

- Any work involving the gas-carrying components (burner, gas valve, ignition electrodes)

- PCB replacement

- Heat exchanger cleaning or replacement

- Fan or air pressure switch faults

- Persistent lockouts after you’ve tried the safe resets above

- Any smell of gas or suspected gas leak

In these cases, turn the boiler off, open windows, and call a Gas Safe registered engineer immediately (or National Gas Emergency Service on 0800 111 999 if you smell gas).

FAQs

My Viessmann boiler shows “Service” or a spanner symbol but no fault code – what should I do?

A spanner symbol is a service reminder, not a fault. Book your annual service; the symbol will disappear once the engineer resets the timer.

Will resetting the boiler multiple times damage it?

Viessmann boilers allow three resets in 24 hours. After that they lock out for safety. Repeated resetting without fixing the cause can wear components, so stop after two attempts.

Is it normal for a Viessmann boiler to make a loud kettle-like noise just before an F2 fault?

Yes – that’s usually the pump struggling or a partial blockage causing localised boiling. Repressurise first, but you’ll likely need a powerflush or pump check.

Can I claim Viessmann boiler repairs on my home insurance or landlord insurance?

Many policies cover “sudden and unforeseen” boiler breakdowns, but not wear-and-tear or lack of servicing. Check your policy schedule for “emergency home cover” or “boiler breakdown cover”. Additionally, it’s essential to keep in mind that regular maintenance can extend the life of your boiler and ensure it operates efficiently. You can also explore home design ideas and inspiration that incorporate energy-efficient systems, which may help reduce the likelihood of unexpected breakdowns. Consider consulting a professional for advice on integrating such solutions into your home.

How long should a Viessmann boiler last in a typical UK home?

With annual servicing and inhibitor, 12–18 years is common. The heat exchanger warranty is usually 10 years on Vitodens 100/200 models if installed by a Viessmann-trained installer.

Stay warm, The Boilers2Go Team

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.