Worcester Bosch boilers are a popular choice across the UK, known for their reliability and energy efficiency. However, like any heating system, they can encounter faults. Each model, from the Greenstar 1000 to the 8000 Life & Style series, has specific error codes that indicate particular issues. Understanding these codes and their common causes can help with quick diagnostics, efficient maintenance, and ensuring safety.

Worcester Bosch Error Codes by Model

Greenstar 1000, 2000, and Greenstar i Series

- A1: Water leak detected or pump issue (frequent in Greenstar 1000 and 2000).

- B1: Code plug not detected (common in Greenstar i and older 2000 models).

- C1: Airflow interruption during operation (Greenstar 1000 and 2000).

- D1: Return temperature sensor error (seen across 1000 and i series).

- F0: Internal error, such as ignition board or PCB fault.

- F7: False flame detection when the boiler is off.

- EA/227: Ignition failure—no flame detected after multiple attempts. Often caused by frozen condensate pipes, faulty gas valves, or flame sensors.

- 1017: Low water pressure (common across all models).

- C7: Fan not running during startup.

Greenstar 4000 Series

- 227: No flame detected after ignition attempts.

- 228: Flame signal detected without an actual flame (sensor or valve issue).

- 1017: Low water pressure.

- 1021/1022: Hot water temperature sensor faults.

- 2924: Modulating gas valve fault.

- 2946: Incorrect code plug detected.

- 208: Maintenance reminder or chimney sweep mode.

- C7: Fan failure during startup.

Greenstar 8000 Life & Style Series

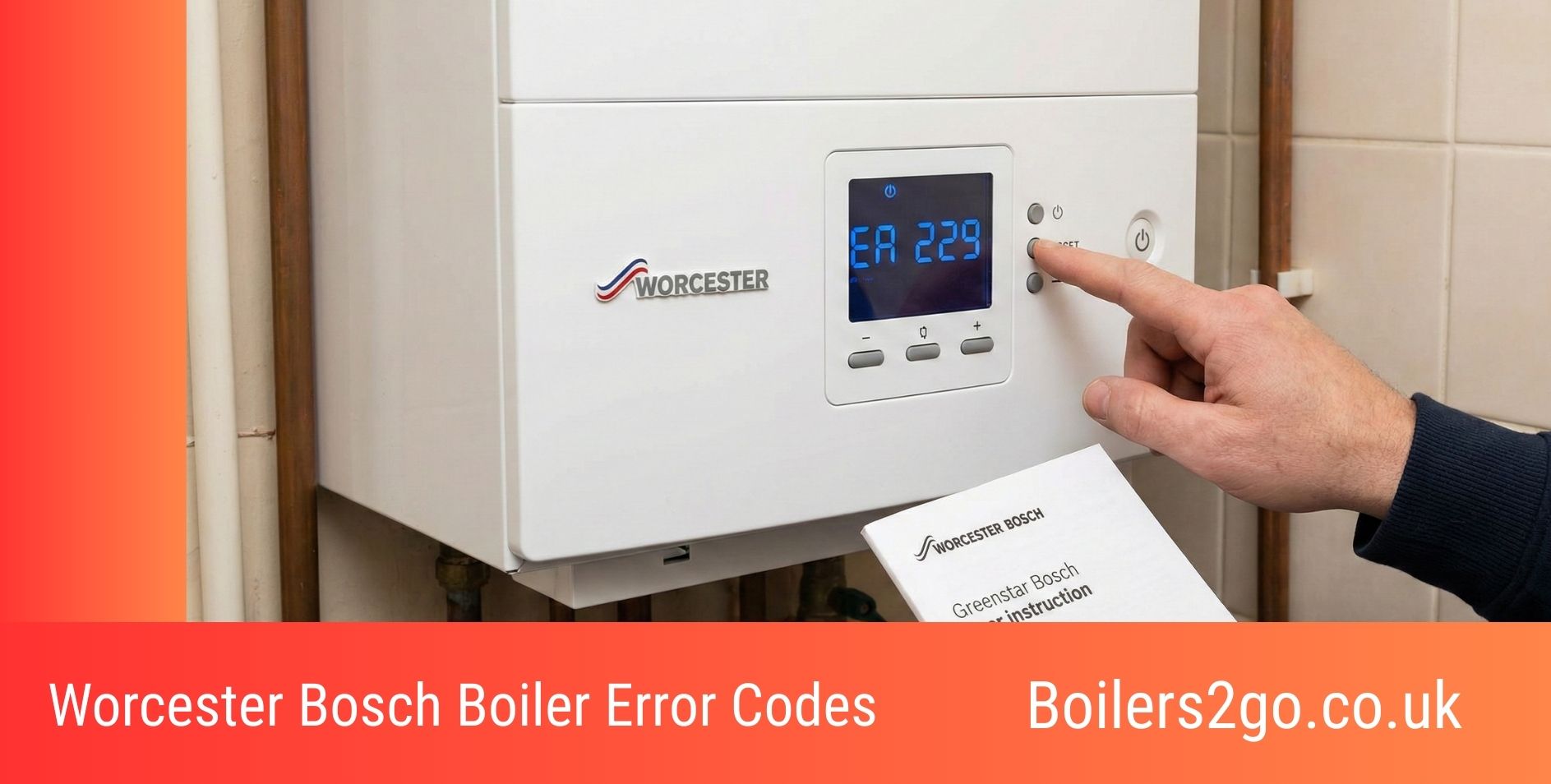

- EA 227: Ignition failure after repeated attempts.

- 224: Safety temperature limiter tripped (overheating).

- 1017: Low water pressure.

- 1021/1022: Hot water sensor failure.

- 2924: Gas valve feedback or relay fault.

- 2946: Code plug communication issue.

- 201-204: Operational status or standby codes.

CDi Classic, Si Compact, and Other Models

- A7: Hot water sensor defect.

- C6: Fan running too fast.

- FA: Flame fault after gas shutoff.

- D5: Condensate pump failure.

- D6: Internal heat bank overflow.

Key Faults and Their Common Causes

EA 227 and Ignition Failures

Frozen condensate pipes are a frequent cause, blocking exhaust flow and preventing startup. Gas supply issues, such as frozen meters or faulty valves, can also restrict ignition. Faulty flame sensors or dirty electrodes may prevent flame detection, while circuit board damage from leaks or moisture can disrupt ignition control.

Low Water Pressure (Code 1017 and Variants)

Low pressure is often caused by leaks in the system, faulty pressure relief valves, or user error, such as failing to repressurise after bleeding radiators. Cold weather can also exacerbate pressure fluctuations.

Troubleshooting and Preventative Tips

- Prevent frozen condensate pipes by insulating them before winter and defrosting them if necessary.

- Regularly monitor boiler pressure and top it up when it drops below recommended levels.

- Schedule annual servicing by a Gas Safe registered engineer to clean flame sensors, inspect gas valves, and check electronics.

- Replace faulty parts, such as pressure relief valves or condensate pumps, early to avoid further damage.

FAQS

Why won’t my Worcester Bosch boiler turn on?

This could be due to low water pressure (check the gauge for 1-1.5 bar), a frozen condensate pipe, or a faulty thermostat. Repressurize the boiler, defrost the pipe, or reset the thermostat. If the issue persists, contact a Gas Safe engineer.

Why is my Worcester Bosch boiler leaking water?

Leaks often result from a faulty pressure relief valve, damaged seals, or internal corrosion. Turn off the boiler and call a professional to inspect and repair it. Regular maintenance can help prevent leaks by ensuring that components are functioning properly and identifying potential issues before they escalate. If you have a Worcester Bosch 4000 combi boiler features, it’s especially important to keep a close eye on its performance, as these advanced systems rely on precise mechanics to operate efficiently. Neglecting maintenance could lead to costly repairs and reduced efficiency in the long run. Additionally, understanding the differences in performance and reliability through a comparison of Worcester Bosch and Vaillant can aid in making informed decisions about your heating system. Each brand has unique strengths that may suit different household needs, so considering user reviews and efficiency ratings is advised. Staying informed about these comparisons can help you choose an optimal boiler that minimizes the risk of leaks and maximizes efficiency.

Why is my Worcester Bosch boiler making strange noises?

Banging or whistling sounds may indicate trapped air, low pressure, or limescale buildup in the heat exchanger. Bleed the radiators, check the pressure, or schedule a service to descale the system.

What should I do if my Worcester Bosch boiler shows low pressure?

Low pressure is usually caused by system leaks or failing to repressurize after maintenance. Use the filling loop to top up the pressure. If it keeps dropping, consult an engineer.

Why is my Worcester Bosch boiler not producing hot water?

A faulty diverter valve, broken thermostat, or limescale buildup could be the cause. A Gas Safe engineer can diagnose and replace faulty parts.

Why does my Worcester Bosch boiler keep switching off?

Frequent shutdowns may be due to overheating, low pressure, or a frozen condensate pipe. Check the pressure, defrost the pipe, and call a professional if the problem continues.

What does an ignition failure error mean on my Worcester Bosch boiler?

This error often points to frozen condensate pipes, a faulty gas valve, or a flame sensor issue. Defrost the pipe and ensure the gas supply is active. If unresolved, contact an engineer.

How often should I service my Worcester Bosch boiler?

Annual servicing by a Gas Safe registered engineer is essential to maintain efficiency, safety, and warranty compliance.

Why are my Worcester Bosch radiators cold at the top?

This is caused by trapped air in the radiators. Bleed them using a radiator key to restore even heating.

Can I fix Worcester Bosch boiler issues myself?

You can handle simple tasks like topping up pressure or bleeding radiators, but complex issues should always be addressed by a Gas Safe engineer to ensure safety and proper repairs.

Understanding model-specific error codes and their causes is essential for keeping Worcester Bosch boilers running efficiently and safely. Addressing common issues like frozen condensate pipes and low water pressure promptly can prevent lockouts and costly repairs. Always consult a qualified Gas Safe engineer for diagnostics and repairs to ensure safe and effective operation. Additionally, it’s important for users to familiarize themselves with common troubleshooting techniques, such as how to reset a boiler, which can resolve minor issues without professional intervention. Regular maintenance checks can also help identify potential problems early, ensuring a longer lifespan for the heating system. Always prioritize safety and never hesitate to reach out to professionals when in doubt.

This guide provides a comprehensive overview of Worcester Bosch boiler error codes, troubleshooting tips, and preventative advice to support both homeowners and professionals. Additionally, the guide delves into common Worcester Bosch blue light issues, helping users identify and resolve problems quickly. With detailed explanations and step-by-step instructions, both homeowners and professionals can feel confident in managing boiler maintenance and repairs. By following the advice provided, users can enhance the longevity and efficiency of their Worcester Bosch systems. For those specifically facing the Worcester Bosch C6 error troubleshooting, this guide offers targeted solutions to quickly rectify the issue and restore system functionality. Furthermore, users will find resources that highlight preventative measures to avoid future errors, ensuring continued peace of mind. Empowering users with knowledge on both routine maintenance and specific error codes fosters a deeper understanding of their heating systems.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.