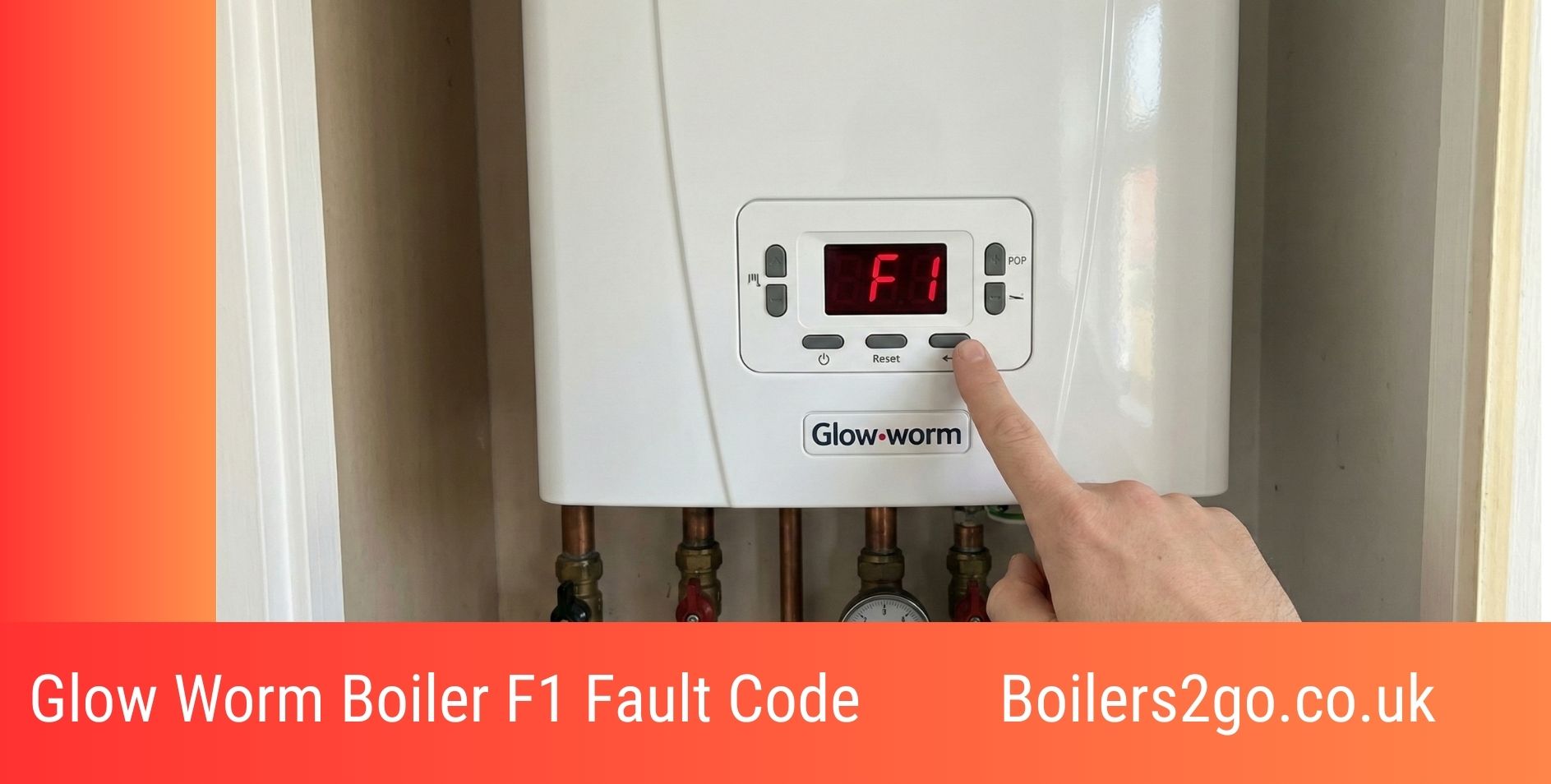

The Glow Worm F1 fault code means the boiler’s printed circuit board (PCB) has sent gas to the burner and sparked the ignition electrode, but it has not detected a flame within the safety time window (usually 5–10 seconds). The boiler then closes the gas valve and displays F1 to protect your home from unburnt gas.

This is a flame-failure or ignition lockout error—not to be confused with F4 (ignition fault without gas) or F22 (low water pressure).

In this guide, I’ll explain the real-world causes of the Glow Worm F1 fault code, and provide step-by-step fixes you can safely try yourself—plus the ones that legally require a Gas Safe registered engineer.

What Causes the Glow Worm Boiler F1 Fault Code?

Here are the proven, most common causes we see on Glow-worm boilers in the UK (in rough order of frequency): Some typical issues include faulty thermistors or pressure switches, which can significantly impact the boiler’s performance. To diagnose the problem accurately, it’s essential to reference the glow worm boiler error codes that provide insight into what’s malfunctioning. Regular maintenance can help prevent these common errors and ensure your boiler operates efficiently. Additionally, understanding the specific issues indicated by the glow worm boiler fault codes explained can aid in quicker troubleshooting and repairs. Homeowners should familiarize themselves with these codes to catch potential problems early, thereby minimizing breakdowns. Moreover, keeping an eye on the boiler’s performance and being proactive with maintenance checks will contribute to its longevity and reliability.

1. Frozen or Blocked Condensate Pipe

In cold weather this is by far the #1 cause of F1 faults on modern condensing Glow-worm boilers.

The condensate pipe (the white plastic pipe that runs outside the house) freezes, blocking the acidic water from leaving the boiler. The boiler detects the blockage via the condensate trap switch and deliberately shows F1 instead of F28 or similar.

2. Low Gas Pressure or Interrupted Gas Supply

If the gas meter pressure is too low, the emergency control valve (ECV) is turned off, or there is an issue with the gas supply pipework, the burner will not light → F1 fault.

3. Faulty Ignition Electrode (Flame Detection Probe)

The combined ignition/flame detection probe gets covered in carbon deposits or cracks over time and can no longer “see” the flame properly, even when one is present.

4. Dirty or Failed Spark Igniter

The spark generator or the electrodes themselves become coated in soot or the ceramic cracks, preventing a strong enough spark to light the gas.

5. Blocked or Dirty Burner

Years of dust and debris can block the burner jets or the burner itself, stopping proper flame establishment.

6. PCB (Printed Circuit Board) Fault

Less common, but the main control board can develop dry solder joints or component failure, causing false F1 faults even when everything else is fine.

7. Gas Valve Problems

The solenoid sticking or calibration drift in the gas valve can stop the correct amount of gas reaching the burner.

How to Fix Glow Worm F1 Fault – Step-by-Step for Each Cause

How to Fix a Frozen Condensate Pipe (Most Common in Winter)

A frozen condensate pipe is something most homeowners can safely fix themselves in 10–15 minutes:

- Locate the condensate pipe (normally 22 mm or 32 mm white plastic pipe exiting the wall outside).

- Pour warm (not boiling) water from a kettle slowly over the frozen section until it thaws.

- Reset the boiler by holding the reset button for 3–5 seconds.

- Once running, insulate the pipe with lagging to prevent it happening again.

How to Fix Low or No Gas Supply

- Check the gas meter — is the handle on the emergency control valve (ECV) in line with the pipe (ON) or across it (OFF)?

- If you smell gas or suspect a leak — evacuate and call the National Gas Emergency Service on 0800 111 999 immediately.

- If the meter shows very low pressure or the boiler still shows F1 after resetting, you need a Gas Safe engineer to check incoming gas pressure (must be ~20–21 mbar at the meter).

How to Clean or Replace the Ignition/Flame Detection Electrode

This must be carried out by a Gas Safe registered engineer:

- Isolate gas and electric.

- Remove and clean the probe with fine emery cloth.

- Gap should be 3.5–4.5 mm.

- If cracked or heavily pitted — replace (genuine Glow-worm part).

How to Fix a Weak or No Spark

Again, Gas Safe only:

- Check for visible strong blue/white spark jumping across the electrodes.

- Clean electrodes and leads.

- If no spark — spark generator or PCB fault.

How to Clean the Burner

Gas Safe engineer required:

- Remove burner assembly.

- Brush and vacuum burner jets and ports.

- Reassemble with new gaskets.

PCB or Gas Valve Replacement

Both of these are 100% Gas Safe engineer jobs — never attempt yourself.

How to Reset a Glow Worm Boiler Showing F1

Most Glow-worm models: Press and hold the reset button (usually marked with a flame and circular arrow) for 3–5 seconds. The display should clear and attempt to fire again. If it locks out again within a minute, stop resetting and call an engineer. If your Glow-worm boiler continues to experience issues, it may be necessary to check the pressure levels. Understanding how to repressurise Glow-worm boilers is essential, as low pressure can lead to lockout situations. Consult your boiler’s manual for step-by-step instructions on safely increasing the pressure and restoring normal function.

How to Prevent the Glow Worm F1 Fault Code in the Future

- Lag the condensate pipe with proper 19 mm thick foam insulation the entire external length.

- Have your Glow-worm boiler serviced every 12 months by a Gas Safe engineer (this catches dirty electrodes, burners and early PCB issues).

- Fit a condensate pro or similar trace-heating kit if the pipe run is long or very exposed.

- Install a magnetic system filter (e.g. Magnaclean or Fernox TF1) and add inhibitor to prevent future burner blockages.

When You Absolutely MUST Call a Gas Safe Engineer

You must call a Gas Safe registered engineer immediately if:

- You smell gas.

- There is no gas supply at all to the property.

- You have reset the boiler three times and it still shows F1.

- The boiler is over 7–8 years old and has never been serviced.

- You can see soot, yellow flame, or the burner looks black/dirty.

- The fault returns within 24–48 hours of a temporary fix (e.g. thawing the condensate).

Working on the combustion side of any gas boiler (burner, electrodes, gas valve, PCB) without Gas Safe registration is illegal in the UK and extremely dangerous.

FAQs

Will my Glow-worm boiler still provide hot water when showing F1?

No. The F1 fault is an ignition lockout, so both central heating and domestic hot water are disabled until the fault is cleared.

Is the F1 fault the same on older Glow-worm models like the Micron or Flexicom?

Yes — the F1 code has been used across the entire Glow-worm range for the last 15+ years, so the causes and fixes are almost identical.

Can a power cut cause an F1 fault on a Glow-worm boiler?

Rarely. A power cut usually triggers an F9 or no display. However, if the boiler was mid-cycle and lost power, it may show F1 on restart if the flame was interrupted.

My boiler shows F1 in summer when I only use it for hot water — why?

Even in summer the boiler still has to ignite every time you run a tap. Dirty electrodes or low gas pressure will still trigger F1 regardless of the season.

How much does it normally cost to fix an F1 fault on a Glow-worm boiler in the UK (2025 prices)?

- Frozen condensate — £0–£90 (most engineers charge a call-out if they thaw it).

- Electrode clean/replace — £120–£220.

- New gas valve — £280–£420.

- New PCB — £350–£550. Prices include parts, labour and VAT.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.