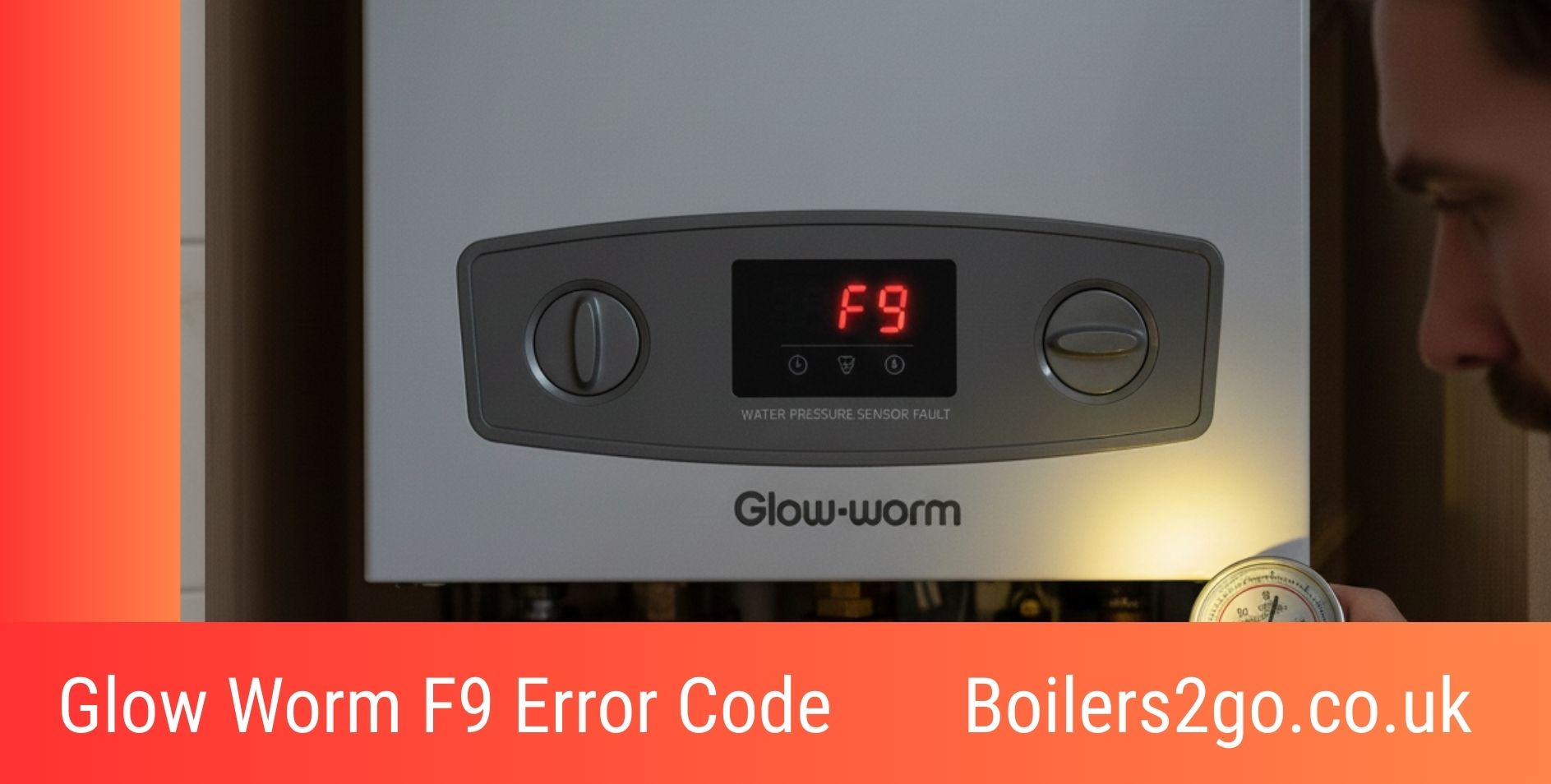

If your Glow-worm boiler is displaying the F9 error code, you’re not alone. Many UK homeowners and landlords experience this common boiler problem—often at the most inconvenient times! Whether you’re seeing the message “Glow-worm boiler F9 fault,” suffering a Glow-worm boiler pressure issue, or your boiler is not heating properly, this guide will help you diagnose the cause and find a solution.

You’ll get clear, practical advice on how to fix F9 error codes on Glow-worm boilers, along with the confidence to know when to safely tackle the problem yourself and when to call in a Gas Safe registered engineer.

What Is the Glow-worm F9 Fault Code?

The F9 error is your boiler’s way of warning you that something is wrong with water movement or system pressure. If water isn’t circulating correctly or the pressure is outside the safe range, the boiler enters lockout for protection. This fault can affect all types of Glow-worm boilers—combi, system, and regular—including models like Energy, Ultimate, and Betacom.

Why Does the F9 Error Code Appear?

Your boiler monitors the system for safe water pressure and flow. If these fall outside the recommended range, it displays the Glow-worm boiler F9 fault. This protects your boiler from damage and keeps your home safe.

Causes of the Glow-worm Boiler F9 Fault

Several issues can lead to a Glow-worm boiler pressure issue or F9 code. Here are the most common:

Low Water Pressure (Below 1 Bar)

Low system pressure (usually below 1 bar) is the most frequent cause of the F9 error on Glow-worm boilers. Often, small leaks in radiators, pipes, or valves slowly reduce pressure over time.

High Water Pressure (Above 2 Bar)

It’s not just low pressure—high boiler pressure (over 2 bar) can also cause the F9 fault. Excess pressure can stress internal components or cause relief valves to vent water, which sometimes leads to error codes like F9.

Faulty Pump

A blocked, seized, or failed pump means water can’t circulate through your radiators. This triggers water flow problems and prompts a Glow-worm boiler F9 fault warning.

Airlocks or Blockages

Airlocks, caused by trapped air in the system, can completely stop water flow, while build-up of sludge or debris may lead to blockages in pipes or components like the heat exchanger and pump. Both can restrict circulation and result in error messages.

Faulty Pressure Sensor or Internal PCB Fault

Sometimes, the sensors send false readings to the PCB (printed circuit board), making your boiler think there’s a pressure issue—when in fact, the real problem is with the sensor or internal electronics. Persistent or recurring F9 codes may point to these less obvious but important faults.

How to Fix the F9 Error: DIY Checks You Can Do

You don’t need to be an engineer to perform a few basic safety checks that may resolve the F9 fault. These steps focus on external parts only and are safe for most confident homeowners.

Important: Never open your boiler casing or attempt internal repairs—this is dangerous and only for Gas Safe registered engineers.

Step 1: Check the Glow-worm Boiler Pressure Gauge

Look at the gauge on your boiler. If it’s below 1 bar, the pressure is too low and you’ll need to re-pressurise. A healthy system should sit between 1 and 1.5 bar, usually shown in the green zone.

If it’s above 2 bar, pressure is too high, which can also trigger an F9 error. In that case, bleeding radiators often helps lower the pressure.

Step 2: How to Re-pressurise Your Glow-worm Boiler

Most modern Glow-worm models feature a filling loop, usually a flexible hose beneath the boiler. Slowly open the valves one by one and allow water in, keeping an eye on the gauge. When you reach 1-1.5 bar, close both valves fully. If the pressure drops below the recommended level, it’s important to know how to repressurise Glow-worm boilers to ensure proper functioning. After closing the valves, check the gauge again to confirm that the pressure remains stable. If necessary, repeat the process or seek professional assistance if you encounter any issues.

If you notice that the pressure drops quickly afterwards, there is likely a leak that needs professional attention. Finish by resetting your boiler to see if the F9 error clears.

Step 3: Bleed Radiators to Release Trapped Air or Reduce High Pressure

If radiators feel unevenly warm or the pressure remains high, turning off your heating and bleeding radiators may solve the problem. Use a radiator key to open the bleed valve—air should hiss out first, followed by a few water drips, at which point you close the valve. After bleeding, always double-check your boiler pressure, and top up if it has dropped below 1 bar. Regularly bleeding your radiators also helps prevent airlocks, which are a common reason for a Glow-worm boiler not heating efficiently.

When Should You Call a Gas Safe Registered Engineer?

While many Glow-worm boiler pressure issues and F9 faults can be resolved with these steps, there are situations when an expert is essential. If your F9 code persists or keeps coming back after basic checks, or if you suspect the pump has failed or there are internal blockages, a Gas Safe registered engineer is required. Additionally, understanding the various glow worm boiler error codes can help in diagnosing issues more accurately. If you encounter frequent F9 errors, it may be indicative of underlying problems that need professional assessment. Always prioritize safety and efficiency by consulting a qualified technician when in doubt about your boiler’s performance. In addition to the F9 error code, the glow worm boiler F75 fault overview is essential for understanding specific issues related to water flow and pressure drops. Recognizing symptoms associated with the F75 fault, such as boiler lockout and low pressure warnings, can also lead to quicker resolutions. Timely intervention not only fixes the current problem but also helps prevent further damage to your system.

Internal leaks, faulty sensors, or problems with the PCB often present as recurring or persistent F9 codes and should always be professionally diagnosed. Likewise, any visible water leaking from inside the boiler should prompt you to turn off the unit and consult an engineer immediately. A qualified engineer has the tools and training to test PCB signals, check the integrity of sensors and wiring, and safely repair your boiler.

Preventative Tips to Avoid the F9 Error

Preventing Glow-worm boiler F9 faults largely comes down to attentive care and regular checks. Arrange an annual service with a Gas Safe engineer, who will inspect and clean your boiler’s components, check the safety valves, and help spot developing issues before they become serious. Make a habit of checking your pressure gauge every month, especially after cold snaps, and bleed your radiators regularly.

If you notice any leaks or a persistent drop in pressure, act quickly to resolve these issues. Fitting a magnetic filter can also reduce the build-up of sludge and debris, further protecting your system.

FAQs

What does the F9 error mean on my Glow-worm boiler?

The F9 code is an alert that your boiler has detected a problem with water circulation or system pressure. This could relate to low or high pressure, a faulty pump, airlocks, or even an issue with pressure sensors.

How do I fix the F9 error on my Glow-worm boiler?

Start by checking your pressure gauge and topping up if it’s low, or bleeding radiators if the pressure is too high or if there’s trapped air. If these actions don’t resolve the problem, consult a Gas Safe engineer. Persistent or recurring F9 errors should always be checked by a professional to rule out hidden leaks or PCB faults.

Is it safe to fix Glow-worm boiler F9 fault myself?

It is safe to carry out simple tasks like topping up pressure or bleeding radiators. However, opening the boiler casing or attempting electrical repairs is both unsafe and illegal unless carried out by a Gas Safe registered professional.

Why does my Glow-worm boiler keep losing pressure?

Ongoing pressure loss is typically due to leaks in the system—whether at radiators, pipe joints, or the pressure relief valve. If you find yourself constantly topping up, it’s important to have an engineer check for internal leaks or faulty components.

Why is my Glow-worm boiler not heating after an F9 error?

Clearing the F9 error often requires resetting your boiler. If it still doesn’t heat up afterward, the underlying issue could be a component fault, such as the PCB, circulation pump, or a blockage—professional assessment is recommended.

How much will it cost to fix the F9 code on my Glow-worm boiler?

Simple DIY fixes like pressure topping-up or bleeding radiators are free. An engineer’s call-out typically ranges from £70–£150, with replacement of parts such as pumps costing between £200–£400 depending on the model and the fault’s complexity.

How can I prevent my Glow-worm boiler from showing the F9 fault?

The best prevention is scheduling regular professional servicing, keeping an eye on pressure levels, bleeding radiators, and addressing any leaks as soon as they appear.

Are Glow-worm F9 repairs covered by my home insurance?

Check your policy details. Some home insurance plans include boiler breakdowns or leaks, while others require separate emergency cover. It’s wise to confirm exclusions and verify any requirements for repairs by accredited engineers.

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.