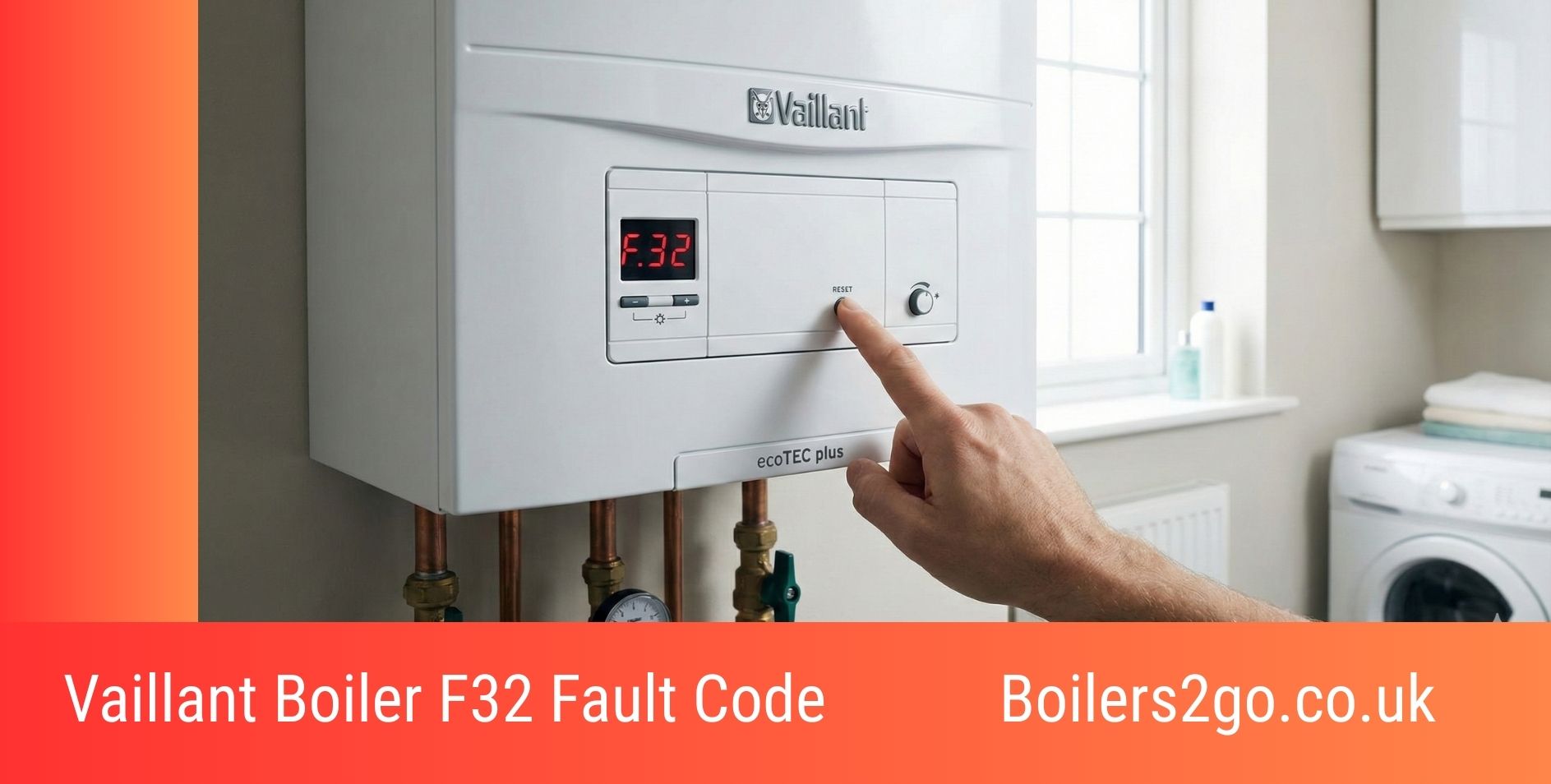

The F32 Vaillant boiler fault code is a common safety alert on Vaillant models like the ecoTEC Plus, Pro and Exclusive ranges, signalling a problem with the air system that prevents safe operation.

In this guide, I’ll explain the meaning of the F32 Vaillant boiler fault code, root causes, and practical fixes, helping you troubleshoot safely before calling in a Gas Safe registered engineer.

What Does the F32 Vaillant Boiler Fault Code Mean?

The F32 Vaillant boiler fault code means there’s a malfunction in the boiler’s air system, specifically related to the fan’s speed control or operation.

In straightforward terms, the fan which pulls in fresh air for combustion and expels dangerous flue gases through the exhaust isn’t running at the correct speed, so the boiler locks out to avoid risks like carbon monoxide buildup in your home.

This fault is exclusive to Vaillant boilers and often appears on ecoTEC series models installed in thousands of UK properties, from family homes in the Midlands to rental flats in London. When F32 shows, the burner won’t ignite, cutting off your radiators and taps until resolved. Commonly, homeowners encounter vaillant boiler radiator symbol issues, which can indicate problems with water flow or pressure within the system. It is crucial to address the F32 fault promptly to avoid further complications, as ignoring it may lead to additional damage and costly repairs. To mitigate these risks, regular maintenance and inspections are recommended to ensure the optimal performance of your Vaillant boiler.

What Causes the F32 Vaillant Boiler Fault Code?

The F32 fault stems from disruptions in the airflow needed for efficient and safe boiler performance. Based on real-world diagnostics from Gas Safe engineers across the UK, here are the primary culprits, each explained with context for why they happen in everyday heating setups. Common issues include blocked flue systems, which can occur due to debris buildup or poor installation, leading to a reduction in necessary air intake. Similarly, a malfunctioning fan might contribute to this fault by failing to adequately circulate air within the unit. For those experiencing trouble with their Vaillant systems, the ‘vaillant boiler f23 fault code explained’ provides crucial insights into potential failures related to ignition and other key components that can also impact overall boiler efficiency.

Cause 1: Faulty or Failing Fan Motor

The fan motor is the heart of the air system in your Vaillant boiler. Over time, especially in dusty lofts or kitchens where the boiler is installed, the motor can wear out, seize up, or fail to reach the required revolutions per minute (RPM) – typically around 5,000–6,000 RPM for ecoTEC models during operation.

This wear might stem from constant use in larger homes with high heating demands or from electrical strain during power fluctuations common in older UK properties.

How to Fix a Faulty Fan Motor Causing F32

- Initial Check: Turn off the boiler at the fused spur and listen for any unusual humming or grinding when you turn it back on – silence or odd noises indicate motor failure.

- Professional Replacement: A Gas Safe engineer will use a diagnostic tool to measure fan speed and confirm the fault. Replacing the fan assembly on a Vaillant ecoTEC typically costs £150–£250, including labour, and takes 1–2 hours.

- Post-Fix Tip: After installation, the engineer recalibrates the fan via the boiler’s service menu to ensure optimal airflow and energy efficiency.

Cause 2: Blocked or Restricted Flue Pipes

Flue pipes carry away exhaust gases from the combustion chamber. Blockages here – from bird nests, leaves, or even ice in harsh UK winters – create backpressure, making the fan work harder and drop below safe speed thresholds, triggering F32.

In exposed locations like coastal homes or those with horizontal flues, wind-blown debris is a frequent offender, especially if the terminal isn’t cowled properly.

How to Fix Blocked Flue Pipes Causing F32

- Visual Inspection: Safely check the external flue terminal (the pipe end outside your property) for obvious obstructions like nests or frost. Use a torch but never climb ladders without safety gear.

- Clearing Debris: For minor blockages, gently use a soft brush or compressed air from a safe distance to dislodge material – avoid forcing anything that could damage seals.

- Engineer Intervention: If the blockage is internal or the flue run is long (over 3 metres), a professional uses a flue brush and CCTV inspection tool. Clearing and resealing costs £80–£150, and they’ll test combustion gases to confirm safety.

Cause 3: PCB Communication Errors

The printed circuit board (PCB) is the boiler’s electronic brain, sending signals to the fan to adjust speed based on demand. A communication glitch – often from loose wiring, corrosion, or water ingress in damp UK bathrooms – means the PCB can’t “talk” to the fan properly, registering it as faulty and locking out with F32.

This is more common in boilers over 5 years old, where vibrations from nearby appliances like washing machines can loosen connections.

How to Fix PCB Communication Errors Causing F32

- Power Cycle: Switch off the boiler at the mains for 10 minutes to reset temporary glitches, then restart and monitor.

- Wiring Check: An engineer inspects and tightens connections on the PCB harness using a multimeter for continuity. This simple fix is often free during a service.

- PCB Replacement if Needed: If corrosion is present, the full PCB swap runs £200–£350. Viessmann or Vaillant-approved boards ensure compatibility, and the engineer updates firmware for better reliability.

Cause 4: Faulty Air Pressure Switch (APS)

The APS monitors airflow pressure to ensure safe combustion. If it’s stuck, dirty, or failed (due to soot buildup from incomplete burns), it falsely signals low pressure to the PCB, mimicking a fan issue and activating F32.

In hard-water areas like the South East, related condensate issues can indirectly affect the APS through moisture.

How to Fix a Faulty Air Pressure Switch Causing F32

- Basic Clean: With the boiler isolated, an engineer removes the APS (a small diaphragm device) and blows out dust with compressed air – a 30-minute job under £100.

- Testing and Replacement: Using a manometer, they check switching pressure (should activate at 0.5–1.0 mbar). New APS units cost £40–£60, fitted in under an hour.

- Prevention: Annual servicing includes APS checks to catch early wear.

Cause 5: Blocked Air Intake or Condensate Issues

The air intake draws in combustion air, and if partially blocked by dust filters or external vents clogged with pollen/snow, the fan can’t maintain speed. Similarly, a frozen or siphoned condensate pipe (the drain for acidic waste water) backs up pressure, indirectly slowing the fan.

This is a seasonal headache for UK landlords with outdoor-exposed pipes in rented properties.

How to Fix Blocked Air Intake or Condensate Issues Causing F32

- Intake Clearance: Vacuum the air intake grille inside the boiler (engineer access only) and check external vents for debris – quick and low-cost.

- Condensate Thaw: Pour lukewarm water over frozen external pipes to melt ice, then insulate with foam lagging (£10 from DIY stores).

- Full Drain: If backed up, the engineer flushes the siphon trap and tests flow, ensuring no acidic leaks damage nearby brickwork.

How to Reset a Vaillant Boiler After Fixing F32

Once the underlying issue is resolved:

- Turn the boiler off at the control knob to the off position.

- Wait 5 minutes for the system to stabilise.

- Turn it back to the on position (heating and hot water symbols).

- Press and hold the reset button (usually a red or black button on the front panel) for 3–5 seconds until the display clears. Do not reset repeatedly without fixes – it risks further damage to the PCB or fan.

FAQs

Does the F32 fault code only appear on specific Vaillant models?

It’s most common on ecoTEC series like the Plus 825 and Pro 30, but can occur on older ecoMAX if the air system shares similar components – check your model’s manual for confirmation.

How does humidity in a UK home contribute to F32 errors?

High indoor humidity, especially in unventilated kitchens, can lead to condensation on the PCB or APS, causing intermittent communication faults that trigger F32 over time.

What role does boiler age play in F32 frequency?

Boilers over 7 years old see F32 up to 40% more often due to natural fan bearing wear, per Gas Safe data – consider a service history review if yours is approaching this milestone.

Can smart controls like Nest exacerbate F32 faults?

Incompatible zoning from third-party thermostats can cause erratic fan demands, mimicking speed issues; always verify Vaillant OpenTherm compatibility for seamless integration.

Is F32 linked to higher energy bills before the lockout?

Yes, a struggling fan runs inefficiently, increasing gas use by 10–15% as the boiler compensates – monitoring for unusual humming can catch it early.

The Boilers2Go Team

I’m Penny North, a home energy heating expert. My mission is to demystify new boilers and complex heating systems to help you achieve a warm, cosy home with lower energy bills and a smaller environmental footprint.